Special water-based acrylic acid modified alkyd anticorrosive paint for steel structures and preparation method thereof

A water-based acrylic and anti-corrosion coating technology, applied in anti-corrosion coatings, coatings and other directions, can solve the problems of restricting the development of water-based steel structure anti-corrosion coatings, huge hidden dangers for people and the environment, and high requirements for substrate treatment, achieving significant economic benefits, The effect of low construction environment requirements and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

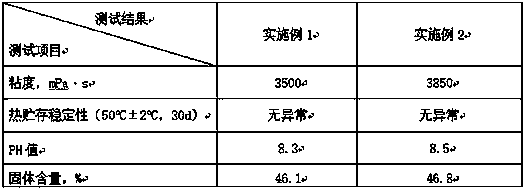

[0046] Embodiment 1 (water-based acrylic modified alkyd resin)

[0047] In a reactor equipped with a stirrer, a condenser, and a heater, weigh 15 g of linoleic acid, 6 g of soybean oil, 6 g of benzoic acid, 5 g of isophthalic acid, 2 g of maleic anhydride, and neopentyl glycol. 7g, 7g of pentaerythritol, and 0.2g of dihydroxybutyl tin chloride, slowly raise the temperature to 150°C and keep it for 1 hour, raise the temperature to 180°C and keep it for 1 hour, raise the temperature to 210°C and keep it for 1.5 hours, then raise the temperature to 220°C and keep it for 1.5 hours. Finally, add 5g of xylene, heat up to 210°C-220°C to keep warm for esterification, keep warm until the acid value is less than 7mgKOH•g -1 , vacuumize to remove xylene, cool down and add 10g propylene glycol methyl ether and 10g 2-tert-butoxyethanol mixed solvent to dilute. Raise the temperature to 120°C-125°C and add dropwise the first two-thirds of the mixed monomer of 10g styrene and 2.5g methacryli...

Embodiment 2

[0048] Embodiment 2 (waterborne acrylic modified alkyd resin)

[0049] In a reactor equipped with a stirrer, a condenser, and a heater, weigh 18 g of linoleic acid, 3 g of soy acid, 4 g of benzoic acid, 5 g of isophthalic acid, 1.5 g of maleic anhydride, and 5 g of alcohol, 8 g of pentaerythritol, and 0.2 g of dihydroxybutyl tin chloride are slowly raised to 150° C. for 1 hour, 180° C. for 1 hour, 210° C. for 1.5 hours, and then 220° C. for 1.5 hours. Finally, add 5g of xylene, heat up to 210°C-220°C to keep warm for esterification, keep warm until the acid value is less than 7mgKOH•g -1, vacuumize to remove xylene, cool down and add 10g propylene glycol methyl ether and 10g 2-tert-butoxyethanol mixed solvent to dilute. Raise the temperature to 120°C-125°C and add dropwise the first two-thirds of the mixed monomer of 15g styrene and 3g methacrylic acid, and drop evenly within 2 hours, then add dropwise the last third of the above-mentioned mixed monomer Add 1.5g of vinyltrie...

Embodiment 3

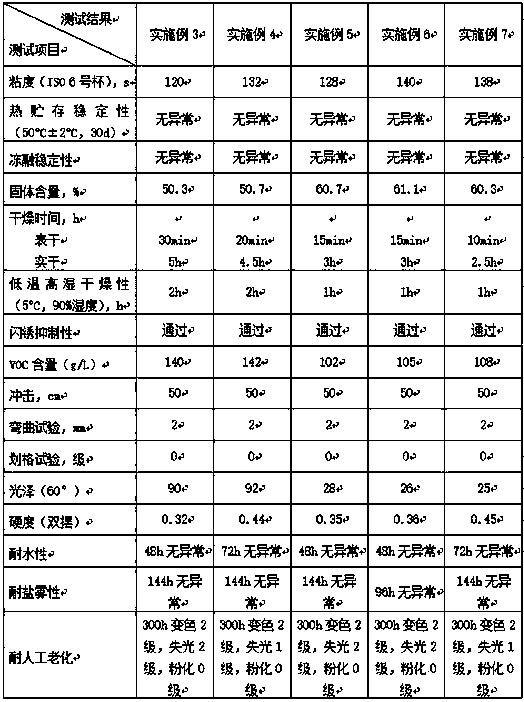

[0051] In the dispersing kettle, put 600g of the resin in Example 1, 2g of dispersant, 60g of deionized water, and 5g of organic bentonite powder into the dispersing kettle. After dispersing evenly at high speed, add 100g of titanium dioxide, 5g of carbon black, 50g of precipitated barium sulfate, and 50g of ferric phosphate. Grind and disperse zinc to a fineness of 40µm, add 3g of leveling aid, 3g of defoamer, 6g of anti-flash rust agent, and 4g of thickener and stir evenly, and adjust the viscosity with the remaining 50g of deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com