Multifunctional rubber asphalt waterproof material as well as preparation method and construction method thereof

A technology of rubber asphalt and waterproof material, applied in the field of materials, can solve the problem of not meeting the requirements of sound insulation, and achieve the effects of excellent adhesion, high thermal stability, and improved wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

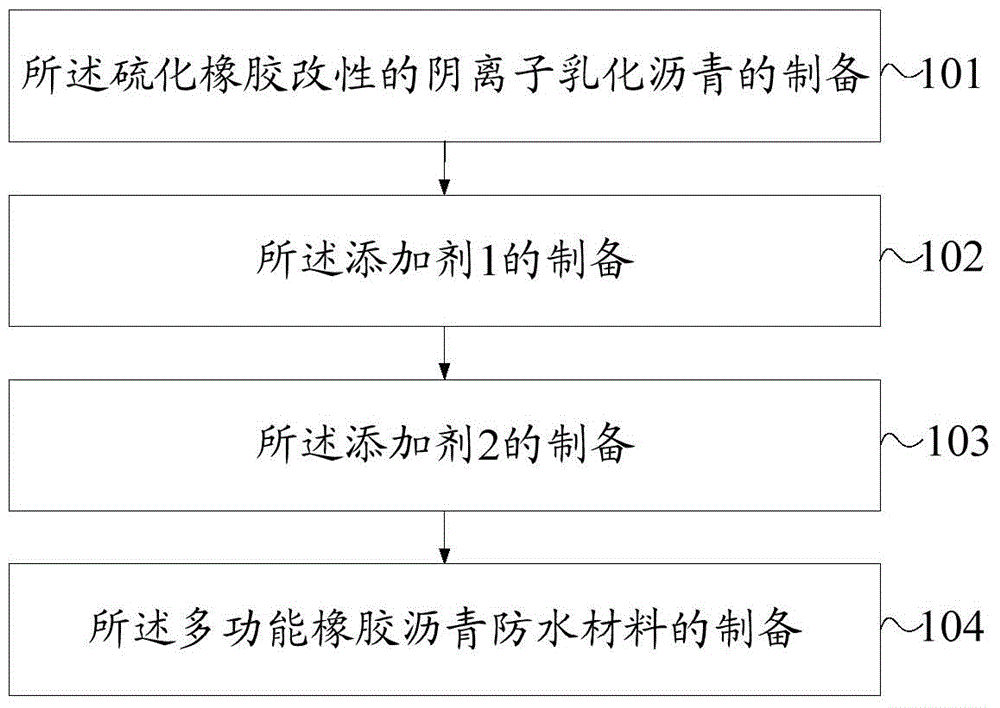

[0043] refer to figure 1 , which shows a flow chart of a method for preparing a multifunctional rubber asphalt waterproof material according to an embodiment of the present invention, the method specifically includes:

[0044] Step 101. Preparation of vulcanized rubber-modified anionic emulsified asphalt: mixing asphalt and vulcanized rubber and emulsifying to prepare vulcanized rubber-modified anionic emulsified asphalt.

[0045] Step 102, preparation of the additive 1: sequentially add silicon dioxide, diatomaceous earth, silane coupling agent, surfactant, wetting agent, dispersant and deionized water and mix to obtain the first mixture, and the first The mixture is dispersed at a rotational speed of 1000-2000 r / min for 1 hour, and then the dispersed first mixture is ground for 1 hour to prepare the additive 1.

[0046] Step 103, the preparation of the additive 2: add surfactant, dispersant, stabilizer, sunscreen, defoamer and anti-aging agent in order to mix, and then disp...

Embodiment 1

[0055] When preparing multifunctional rubber asphalt waterproof material, mix 90kg of vulcanized rubber-modified anionic emulsified asphalt and 10kg of rubber emulsion, then mix with 0.7kg of additive 1 and 0.6kg of additive 2, and then mix the material mixture at 150r / Disperse for 1 hour at a speed of 1 min, and mix well to prepare a multi-functional rubber asphalt waterproof material. Among them, 90kg of vulcanized rubber-modified anionic emulsified asphalt includes 63kg of asphalt and 27kg of vulcanized rubber.

[0056] The total weight of additive 1 is 0.7kg, which contains 0.1kg of silicon dioxide, 0.1kg of diatomaceous earth, 0.1kg of silane coupling agent, 0.1kg of rosin soap and fatty acid soap, 0.1kg of wetting agent, 0.1kg Polynaphthalenesulfonate sodium salt and 0.1kg of deionized water to obtain the first mixture, the first mixture is dispersed at a speed of 1000r / min, the dispersion time is 1h, and then the dispersed first mixture Grinding treatment was carried ...

Embodiment 2

[0059] When preparing multifunctional rubber asphalt waterproof material, mix 30kg of vulcanized rubber-modified anionic emulsified asphalt and 70kg of rubber emulsion, then mix with 12kg of additive 1 and 10kg of additive 2, and then mix the material mixture at 200r / min Disperse for 1 hour at a rotating speed, and make a multifunctional rubber asphalt waterproof material after stirring evenly.

[0060] Among them, 30kg of vulcanized rubber-modified anionic emulsified asphalt includes 29.1kg of asphalt and 0.9kg of vulcanized rubber.

[0061] The total weight of additive 1 is 12kg, which contains 2kg of silicon dioxide, 2kg of diatomaceous earth, 2kg of silane coupling agent, 2kg of nonylphenol ethoxylate, 1kg of wetting agent, 1kg of dispersing agent and 2kg The composition of deionized water is to obtain the first mixture, and the first mixture is dispersed at a speed of 2000r / min for 1 hour, and then the dispersed first mixture is ground for 1 hour to obtain Additive 1, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com