Steel bridge floor pavement structure containing polyurethane modified polymers

A polyurethane modification and steel bridge deck technology, which is applied to the coagulation pavement, bridges, bridge parts and other directions laid on site to achieve the effect of low construction environment requirements, good deformation ability and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

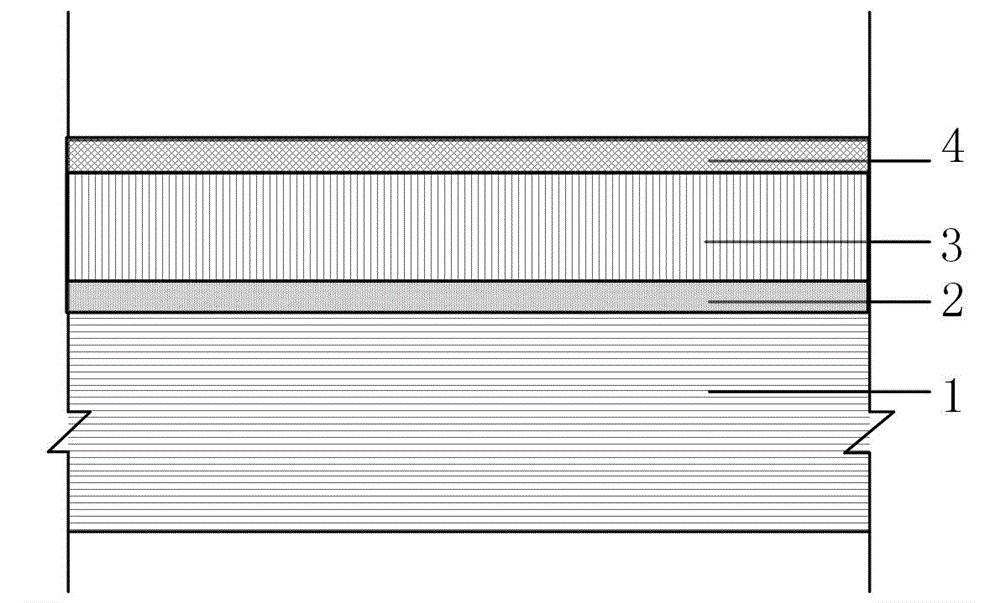

[0019] see figure 1 , one A polyurethane modified polymer steel bridge deck pavement structure comprises a steel bridge deck 1, an intermediate layer 3 is laid on the steel bridge deck 1 through an adhesive layer 2, and a wearing layer 4 is laid on the intermediate layer 3.

[0020] The material of the bonding layer 2 is two-component polyurethane modified resin special glue, and the thickness of the bonding layer 2 is 1-2mm; the material of the middle layer 3 is two-component high thixotropic polyurethane modified polymer gravel, The thickness of the middle layer 3 is 6-7 mm; the material of the wearing layer 4 is two-component polyurethane modified polymer gravel, and the thickness of the wearing layer 4 is 2-3 mm.

[0021] The materials of the bonding layer 2, the intermediate layer 3 and the wearing layer 4 are all cured at room temperature.

[0022] Concrete construction steps of the present invention are as follows:

[0023] (1) The surface of the steel bridge deck 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com