Steel bridge deck laying structure

A steel bridge deck and pavement technology, which is applied to bridges, bridge parts, bridge materials, etc., to achieve the effects of light weight, high strength and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

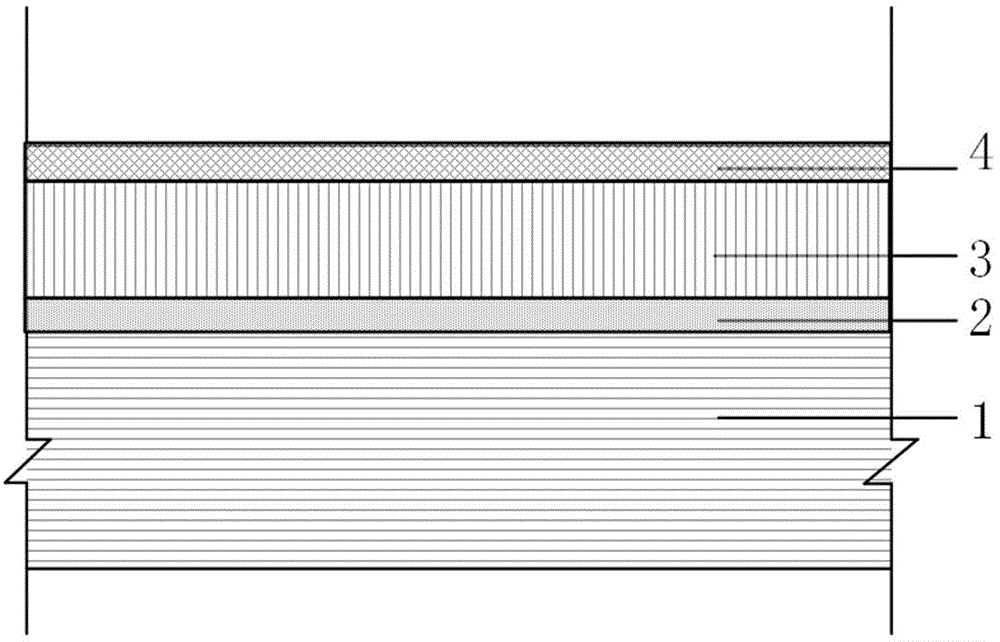

[0021] see figure 1 , a steel bridge deck pavement structure, comprising a steel bridge deck 1, an elastic crack-resistant layer 3 is laid on the steel bridge deck 1 through a bonding layer 2, and a wear layer 4 is arranged on the elastic crack-resistant layer 3.

[0022] The material of the bonding layer 2 is a two-component polyurethane modified resin special adhesive, and the thickness of the bonding layer 2 is 1-1.5mm; the material of the elastic anti-cracking layer 3 is a two-component high thixotropic pure elastic polyurethane modified The thickness of the elastic anti-cracking layer 3 is 6-7 mm; the material of the wearing layer 4 is two-component polyurethane modified polymer gravel, and the thickness of the wearing layer 4 is 3-5 mm.

[0023] The materials of the adhesive layer 2, the elastic anti-crack layer 3 and the wear layer 4 are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com