Anticorrosive coating for steel structure in alkaline steam environment and preparation method thereof

A technology for anti-corrosion coatings and steel structures, applied in anti-corrosion coatings, coatings, etc., can solve the problems of high curing temperature of silicone resin, poor adhesion and solvent resistance, poor weather resistance, etc., achieve super weather resistance, reduce labor Effect of increased strength, environmental protection and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following examples are used to illustrate the present invention, but not to limit the scope of the present invention. Without departing from the spirit and essence of the present invention, modifications or substitutions made to the methods, steps or conditions of the present invention fall within the scope of the present invention. The chemical raw materials used in the examples are all conventional commercially available raw materials.

[0040] In the following, the present invention will be further described in conjunction with embodiments.

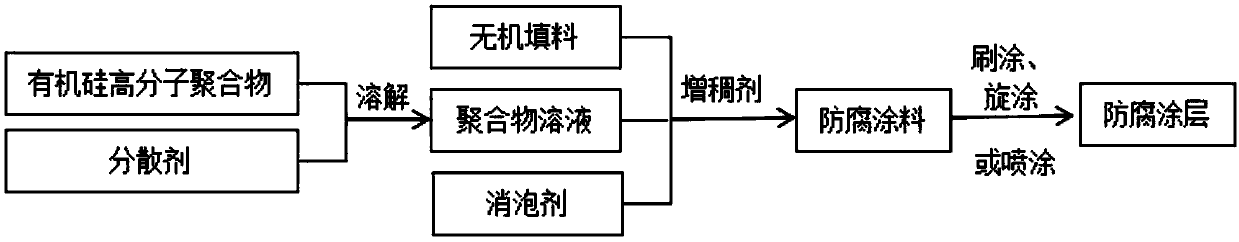

[0041] Such as figure 1 As shown, first, prepare organosilicon high molecular polymer anticorrosive coating according to the following steps:

[0042] (1) Weigh 300 grams of polysilazane and add 1L of petroleum ether to dissolve it to prepare an organic silicon polymer solution;

[0043] (2) Add inorganic filler nano SiO2 powder, Al 2 O 3 Powder, TiO 2 Powder and defoamer, disperse at high speed for 20 minutes, stir evenly;

[0044]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com