Polyurethane plastic material and preparation method thereof

A plastic material and polyurethane technology, applied in the field of polyurethane plastic material and its preparation, can solve the problems of large foaming ratio of plastic material, failure to meet national standards, and great influence of air humidity, and achieve average bubble size, stable speed, and stable response Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

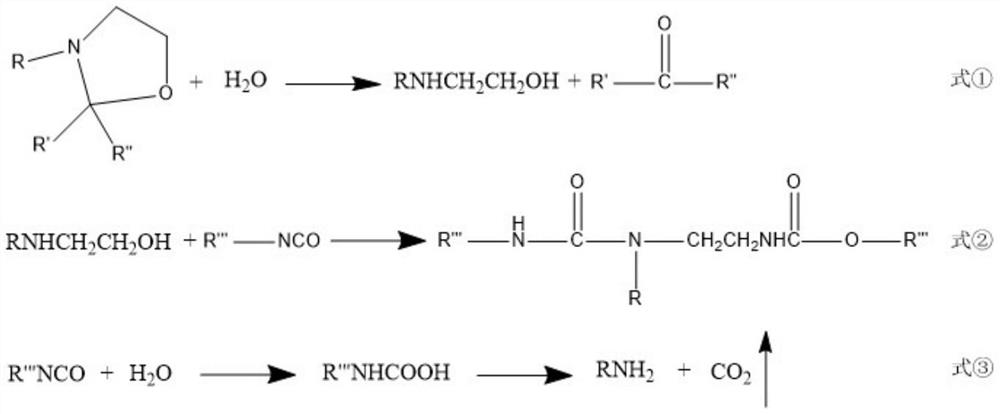

Method used

Image

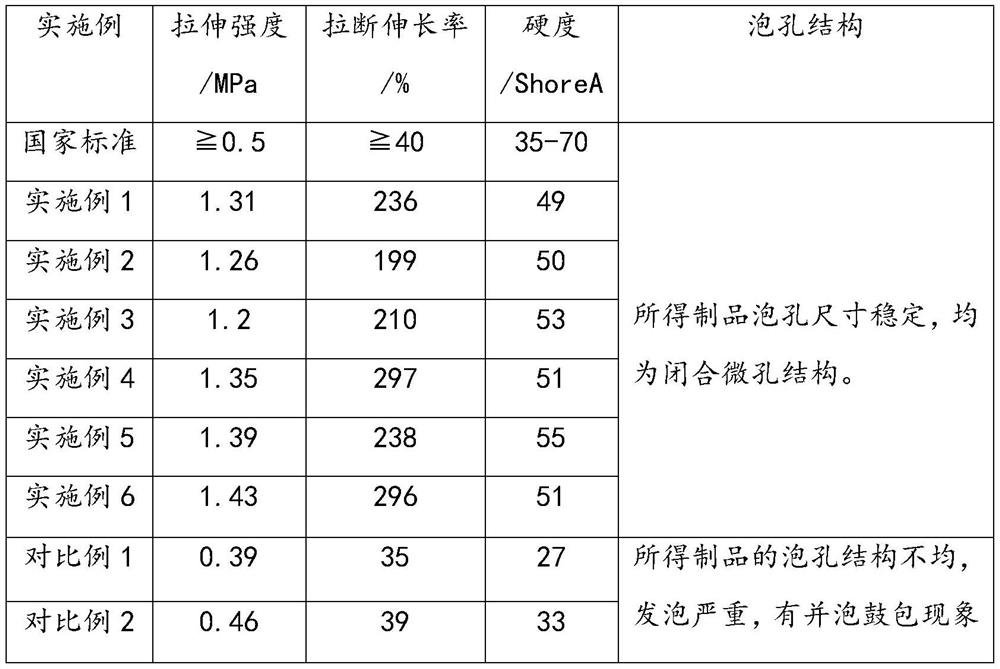

Examples

Embodiment 1

[0047] A kind of polyurethane plastic material, the raw material that its preparation adopts and consumption are as shown in table 1:

[0048] Table 1 Embodiment 1 raw material ratio table

[0049] raw material name parts by mass 330N 55 220 30 210 15 Chlorinated paraffin 50 BYK-W961 1 Iron Oxide Red 3 1010 1 heavy calcium 150 Titanium dioxide 5 light calcium 10 MDI-50 20 ALT-101 2 phosphoric acid 0.3

[0050] The preparation method of the polyurethane plastic material of the present embodiment is as follows:

[0051] (1) Polyether polyol (330N, 220, 210), plasticizer (chlorinated paraffin), wetting and dispersing agent (BYK-W961), inorganic filler (heavy calcium, titanium dioxide, light calcium), colorant (Red iron oxide) and antioxidant (1010) were put into the reaction kettle, dehydrated at a temperature of 110-120°C and a pressure of -0.1MPa until the water content of the system was low...

Embodiment 2

[0057] A kind of polyurethane plastic material, the raw material that its preparation adopts and consumption are as shown in table 2:

[0058] Table 2 Embodiment 2 raw material ratio table

[0059] raw material name parts by mass 330N 60 220 30 210 10 Epoxidized soybean oil 50 BYK-W961 1 Iron Oxide Red 3 1010 1 heavy calcium 150 talcum powder 5 light calcium 20 MDI-50 20 RGT23416 2 phosphoric acid 0.3

[0060] The preparation method of the polyurethane plastic material of the present embodiment:

[0061] Different from Example 1, the plasticizer of the present embodiment adopts epoxy soybean oil; Inorganic filler adopts heavy calcium, talcum powder and light calcium; Oxazolidine adopts RGT23416; In step (1) and step (2), Cool down to 60°C after dehydration.

[0062] Others are the same as in Embodiment 1, and will not be repeated here.

[0063] In this example, a polyurethane plastic ma...

Embodiment 3

[0065] A kind of polyurethane plastic material, the raw material that its preparation adopts and consumption are as shown in table 3:

[0066] Table 3 Embodiment 3 raw material ratio table

[0067] raw material name parts by mass 330N 70 220 30 Chlorinated paraffin 35 Epoxidized soybean oil 15 BYK-W961 1 Iron Oxide Red 3 1010 1 heavy calcium 130 Kaolin 5 light calcium 20 MDI-50 20 ALT-101 2 phosphoric acid 0.3

[0068] The preparation method of the polyurethane plastic material of the present embodiment:

[0069] Different from Example 1, the polyether polyol of the present embodiment adopts 330N and 220; Plasticizer adopts epoxy soybean oil and chlorinated paraffin; Inorganic filler adopts heavy calcium, kaolin and light calcium; Step (1) and In step (2), the temperature is lowered to 55°C after dehydration.

[0070] Others are the same as in Embodiment 1, and will not be repeated here...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com