Waterborne electrostatic epoxy anticorrosive primer for wheel shafts and preparation method thereof

An anti-corrosion primer and electrostatic ring technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as operator health threats and air pollution, and achieve good chemical resistance and adhesion. Strong focus, good physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

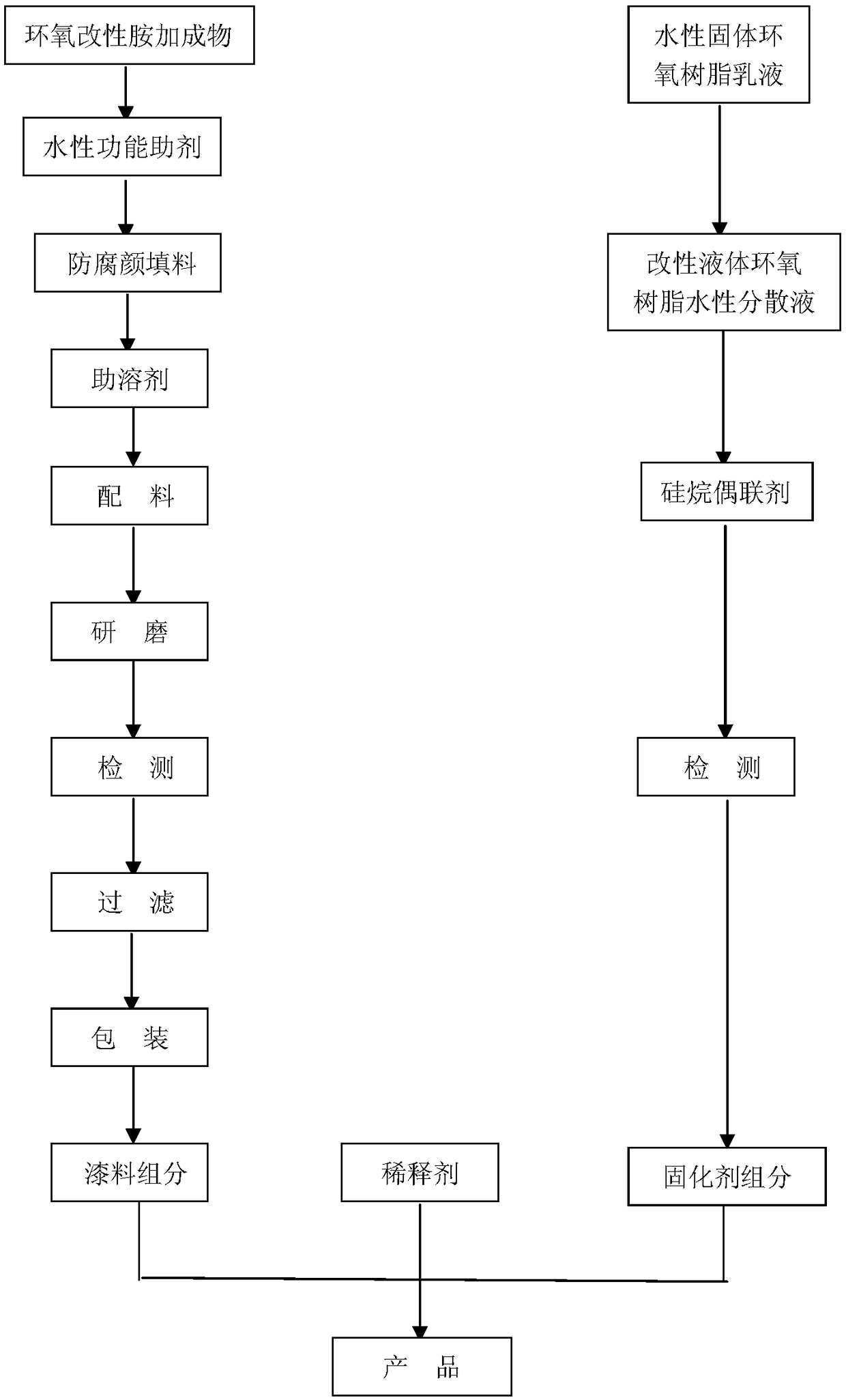

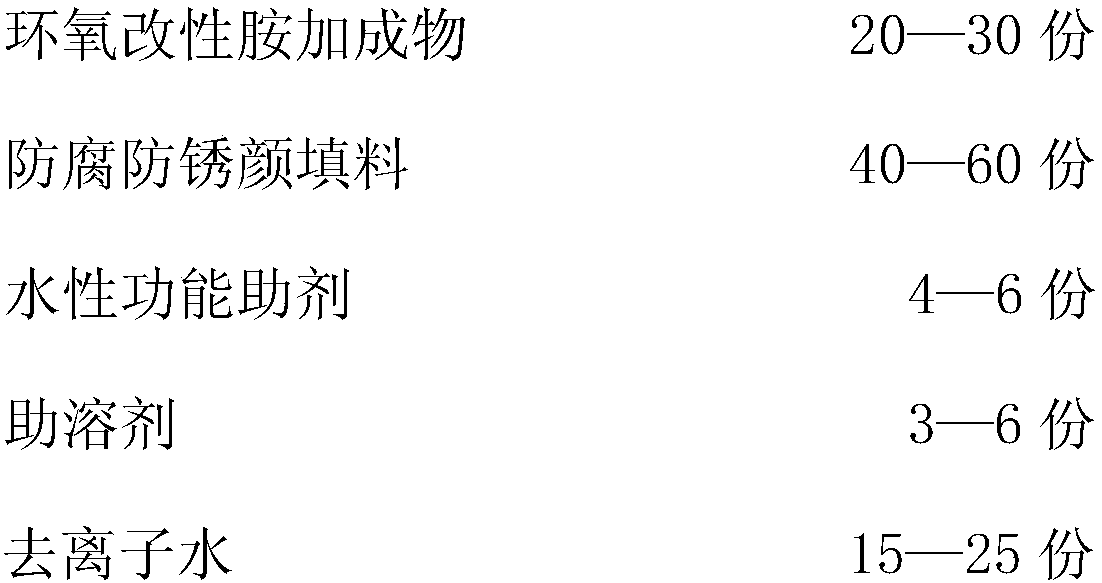

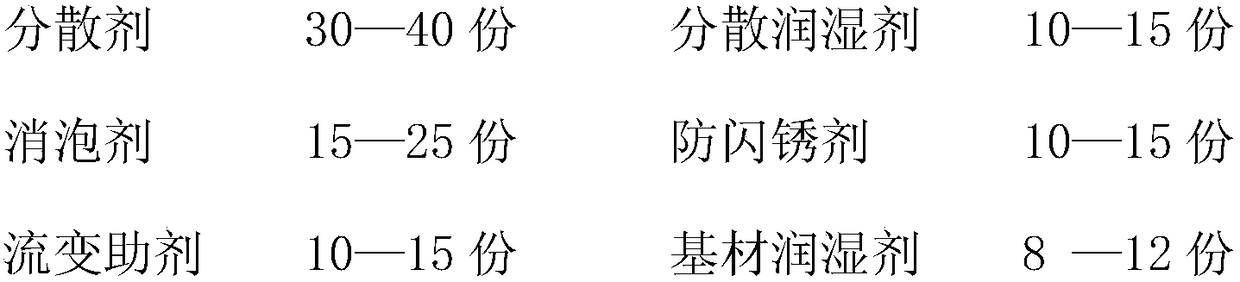

[0060] A. Preparation of primer paint: Add the raw materials of each component of the water-based electrostatic epoxy anti-corrosion primer paint required for production according to the above weight ratio, and add rings in turn under low-speed stirring (600-800 rpm). Oxygen-modified amine adducts, water-based functional additives, anti-corrosion and anti-rust pigments and fillers, co-solvents, deionized water. After the feeding is completed, under high-speed stirring (800-1000 rpm) for about 10-15 minutes, the pre-dispersed slurry of primer paint can be obtained. Then use an air pump to pump it into a sand mill, grind it to a fineness of ≤40μm, and discharge it to become the primer paint component.

[0061] B. Filtration and packaging: filter the above-mentioned paint material in an 80-mesh sieve to remove mechanical impurities, and produce a finished paint material, which is packed in a plastic bucket for use.

[0062] C. Preparation of curing agent: put water-based solid e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com