Sinusoidal optical pressure sensitive coating dynamic pressure calibration chamber

A dynamic pressure, sinusoidal technology, applied in the direction of measuring fluid pressure, measuring devices, instruments, etc., to achieve the effect of easy processing, accuracy assurance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

[0032] The concrete technical scheme that the present invention adopts is:

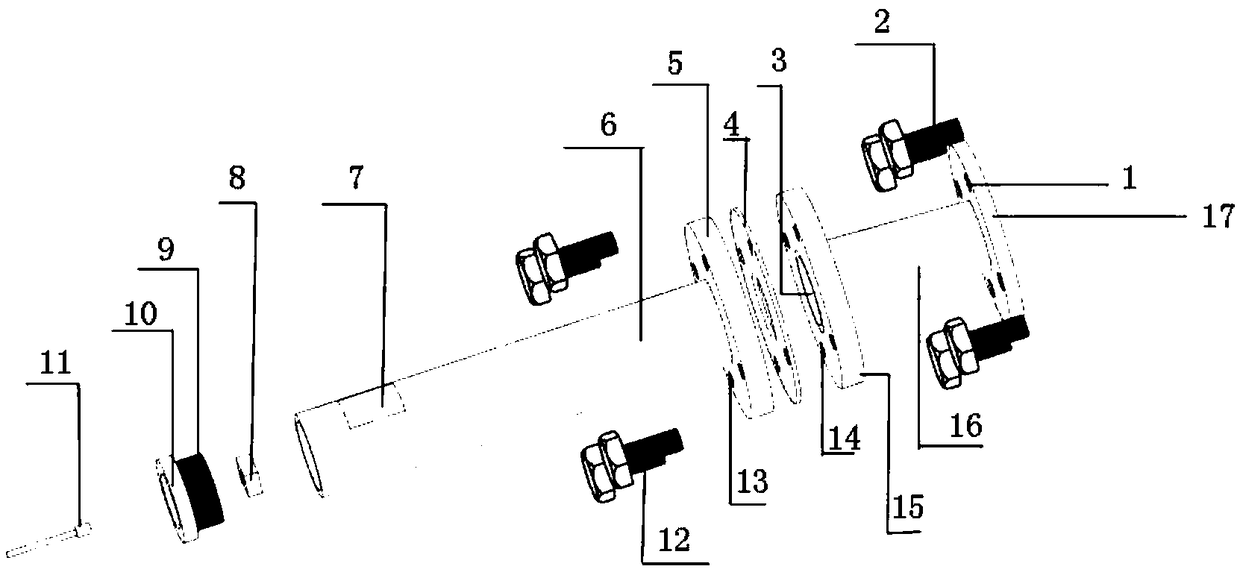

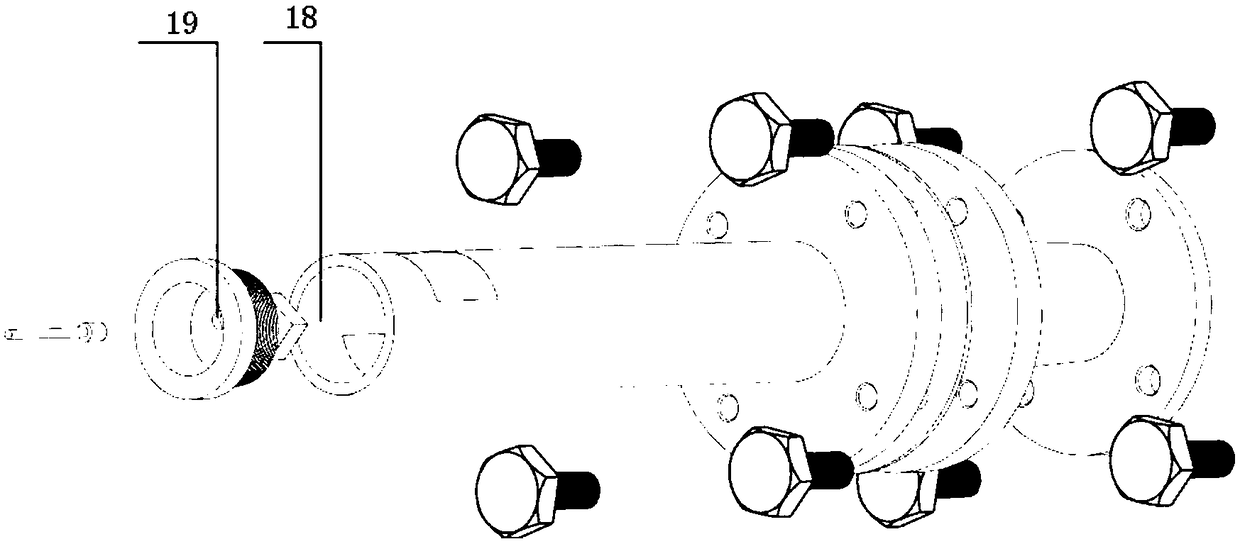

[0033] It is composed of the first flange 5, the second flange 15 and the third flange 17, the adapter section 16, the main body section 6, the bottom cover 10, the transparent window section 7, the sealing rubber ring 4, and the optical pressure-sensitive calibration sheet 8. Calibration cabin. The dynamic calibration test bench is composed of woofer / tweeter, dynamic calibration cabin, photomultiplier tube (PMT), pressure sensor, data acquisition card and host.

[0034] 1. The establishment of dynamic calibration cabin

[0035] a. Comparing the cut-off frequency formula of rectangular section In the case of polar symmetric vibration of the sound source, the cut-off frequency formula of the circular section Under the condition of the same cross-sectional area, the cut-off frequency...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Small end diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com