Single membrane capacitance type microphone chip

A condenser microphone and microphone technology, applied in the field of microphones, can solve the problems of complex manufacturing process, poor frequency response characteristics of microphones, and high mechanical sensitivity, and achieve the effects of simple manufacturing process, broadband characteristics, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

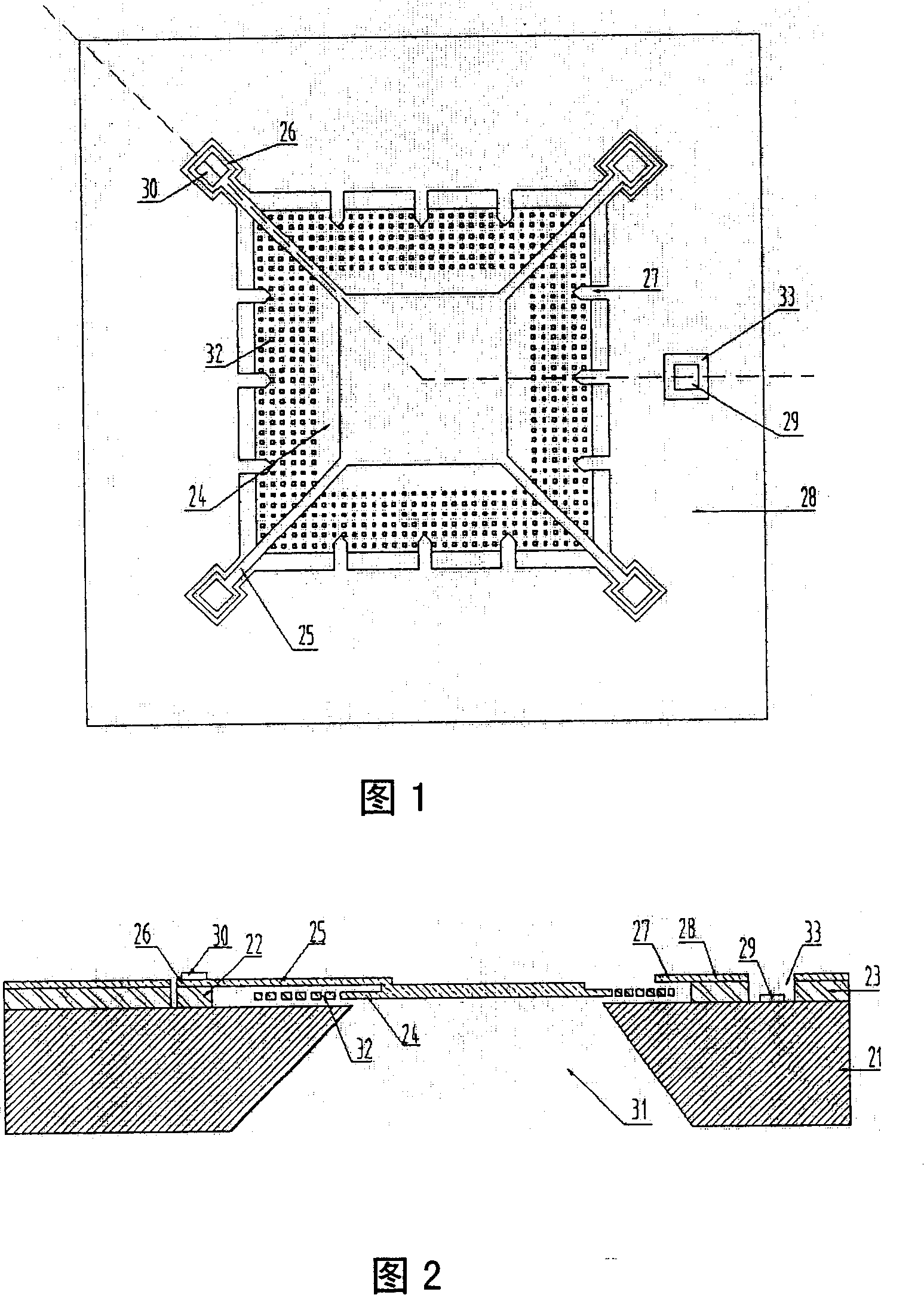

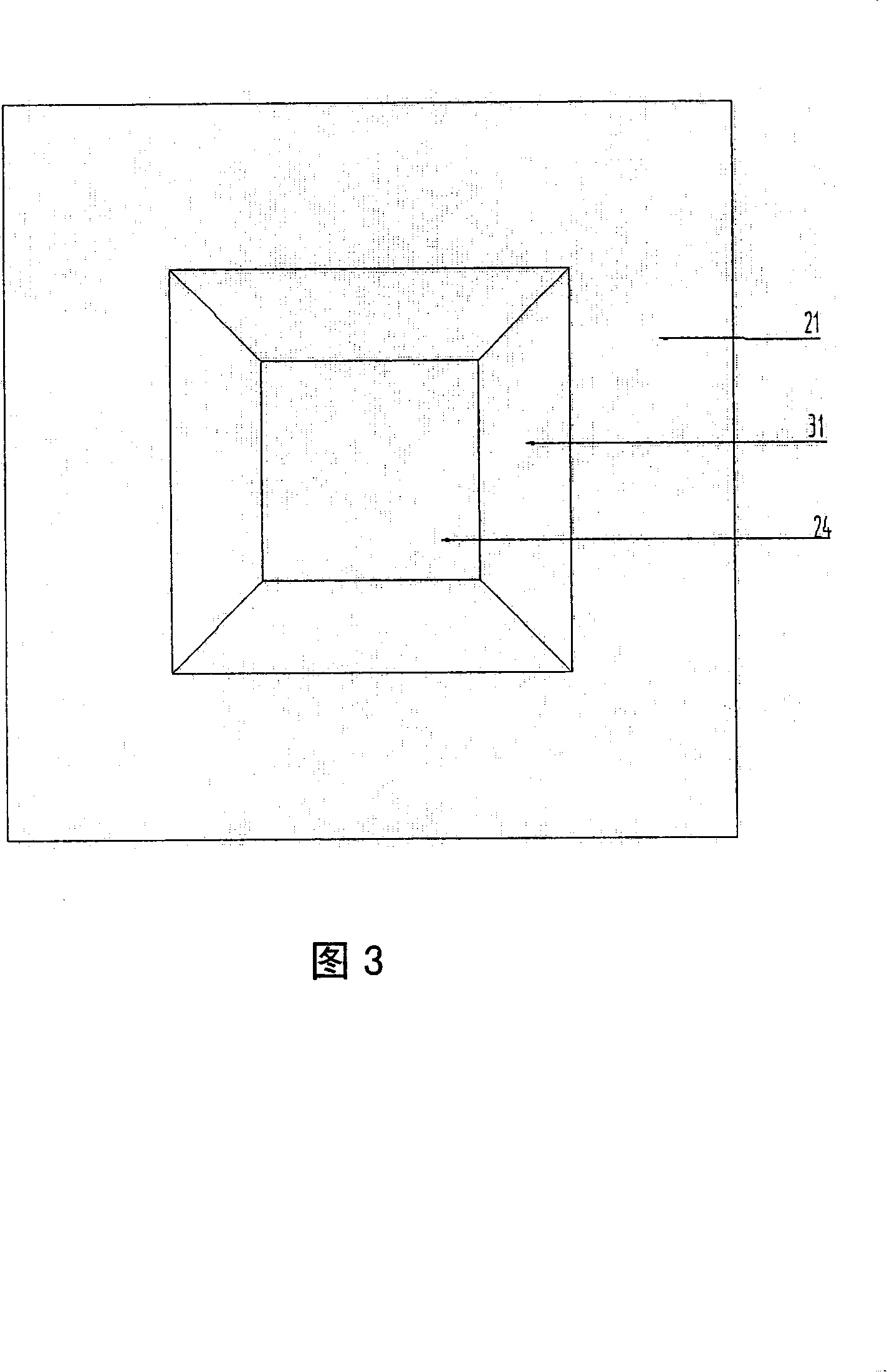

[0037] As shown in Figures 1-3, Embodiment 1 of the present invention is a single-membrane condenser microphone chip structure of the present invention, as shown in Figures 1 and 2, which is characterized by a single-membrane with a cantilever beam on the top and a diaphragm on the bottom Structure, from bottom to top: base 21, cantilever support 22, stopper support 23, diaphragm 24, cantilever beam 25 and cantilever frame 26, stopper 27 and stopper frame 28, and lower electrode 29, upper electrode 30 , the edge of the diaphragm 24 and the base 21 form a capacitive structure.

[0038] Wherein, there is a through hole in the center of the base 21, which is the back cavity 31, and the upper surface of the base 21 is fixedly connected with a frame-shaped stop support 23, and the upper surface of the stop support 23 is fixedly connected with a frame-shaped stop frame 28, and the center of the stop support 23 and The square through hole in the center of the stop frame 28 is similar...

Embodiment 2

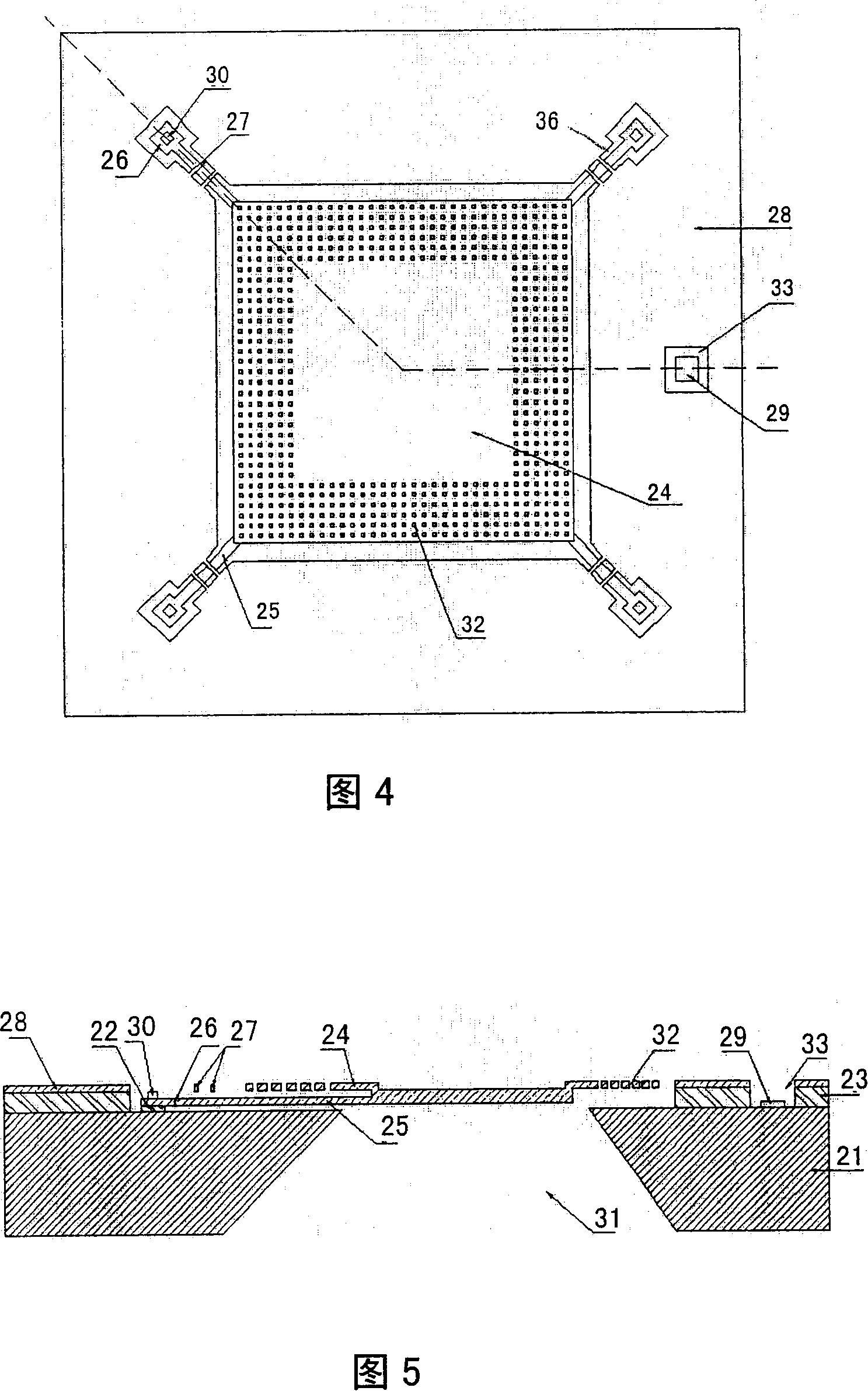

[0049] As shown in Figure 4-6, it is the second embodiment of the present invention, which is another single-membrane condenser microphone structure in the present invention, as shown in Figure 4 and Figure 5, the basic structure and materials used are the same as the first embodiment, from the bottom On the top are: base 21, cantilever support 22, stopper support 23, cantilever beam 25 and cantilever frame 26, diaphragm 24, stopper 27 and stopper frame 28, as well as lower electrode 29, upper electrode 30, diaphragm 24 The edge and base 21 form a capacitive structure. It is characterized by a single-membrane structure with the diaphragm 24 on top and the suspension beam 25 on the bottom. Simultaneously, at the periphery of the through hole at the center of the stop frame 28, a plurality of evenly arranged toothed anti-vibration stoppers 27 extending horizontally into the hole are removed, while the through holes at the center of the stop support 23 and the center of the stop ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com