Multistage differential pumped ultrahigh vacuum sample transmission mechanism

An ultra-high vacuum, sample transfer technology, applied in the direction of analytical materials, instruments, etc., can solve the problems of low work efficiency, lack of ownership, long time, etc., to achieve the effect of improving experimental efficiency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

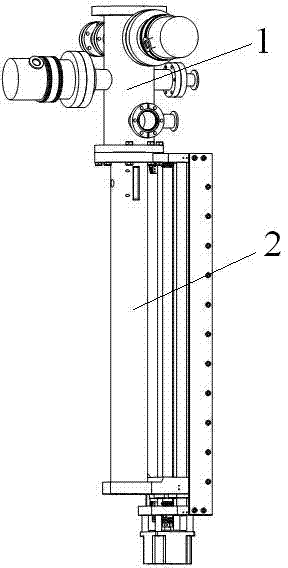

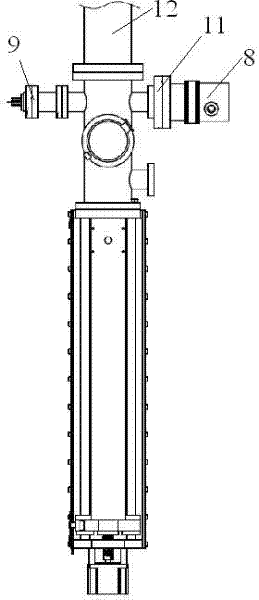

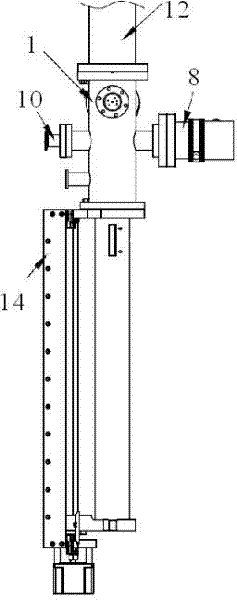

[0017] Such as figure 1 The four-stage differential pumping ultra-high vacuum sample transfer mechanism shown in -3 is composed of a differential pumping mechanism 1 and a sample transfer rod driver 2, and the differential pumping mechanism 1 is as follows: Figure 4 As shown, the U-shaped sealing ring 6 is used to separate the U-shaped sealing ring in the cavity and is supported by the spacer ring 7 to form three spaces, namely, the first differential pump 3, the second differential pump 4 and the third differential pump 5. Each differential The pumping space has an independent vacuum obtaining mechanism and detection mechanism 9, and the first-stage differential pumping space is fixedly connected with the sample transfer rod driver through a flange. The blue is connected with the ultra-high vacuum chamber, and the vacuum obtaining ability of each differential pumping space is enhanced sequentially. The highest-level differential pumping space is fixedly connected with the ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com