Construction method for subsurface excavated underground pipe rack and storage well

A technology of underground pipe gallery and construction method, which is applied to artificial islands, earthwork drilling, water conservancy projects, etc., can solve the problems of long time for completion and delivery, high cost, etc., achieve broad market prospects and social value, low cost and fast speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

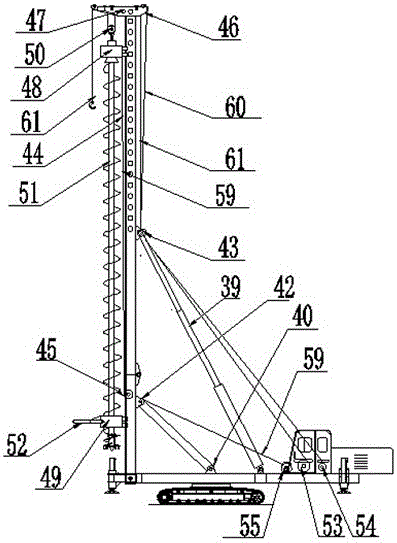

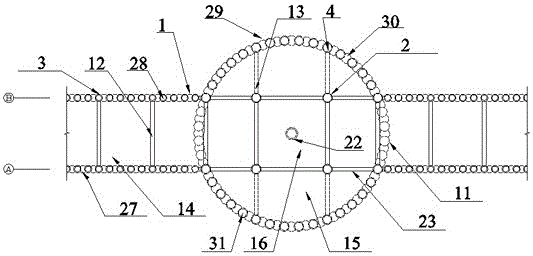

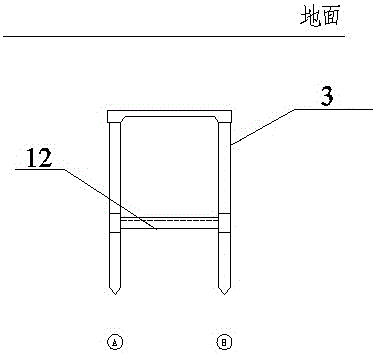

[0040] A construction method for digging underground pipe galleries and storage wells, such as Figure 1-5 shown, including the following steps:

[0041] Step 1: Level the site, measure and place the piles, and pour the concrete guide wall of the occlusal piles;

[0042] Step 2: Use a portable pile driver to construct a concrete occlusal pile composed of plain concrete water-stop piles, reinforced concrete support piles, and reinforced concrete load-bearing piles, which are used as concrete occlusal piles for the pipe gallery wall and the water storage well wall Concrete occlusal pile two 29, construct 4 pile diameters in the storage well again and be the reinforced concrete bearing column pile 2 of 80cm; The pile diameter of concrete bearing pile one 3 is 60cm, and the pile diameter of plain concrete water stop pile two 30, reinforced concrete support pile two 31, reinforced concrete bearing pile two 4 of reservoir well wall is 80cm;

[0043]Step 3: One week after the compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com