Testing method for glass deflection

A test method and deflection measurement technology, which is applied in the direction of elasticity test, machine/structural component test, measuring device, etc., can solve the problem of inability to measure glass deflection, etc., and achieve the effect of strong practicability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for testing the deflection of float glass, comprising the following steps:

[0026] Step 1. Cutting pattern: Select a 1.7mm thick float glass plate to be tested, and cut the float glass plate to be tested into a rectangular glass pattern of 1000mm×600mm.

[0027] Step 2, pattern mark: mark the center point of the tin liquid surface and the center point of the air surface of the glass pattern. The mark is an opaque circular coating with a diameter of 3mm uniformly applied by a red oily marker. During the coating process, it must be applied evenly, and there must be no leakage of coating, so as to avoid the problem of inaccurate data caused by the transmission of infrared rays through the glass.

[0028] Step 3, zeroing the deflection measuring device: use a plate without deflection to zero the deflection rangefinder in the deflection measuring device.

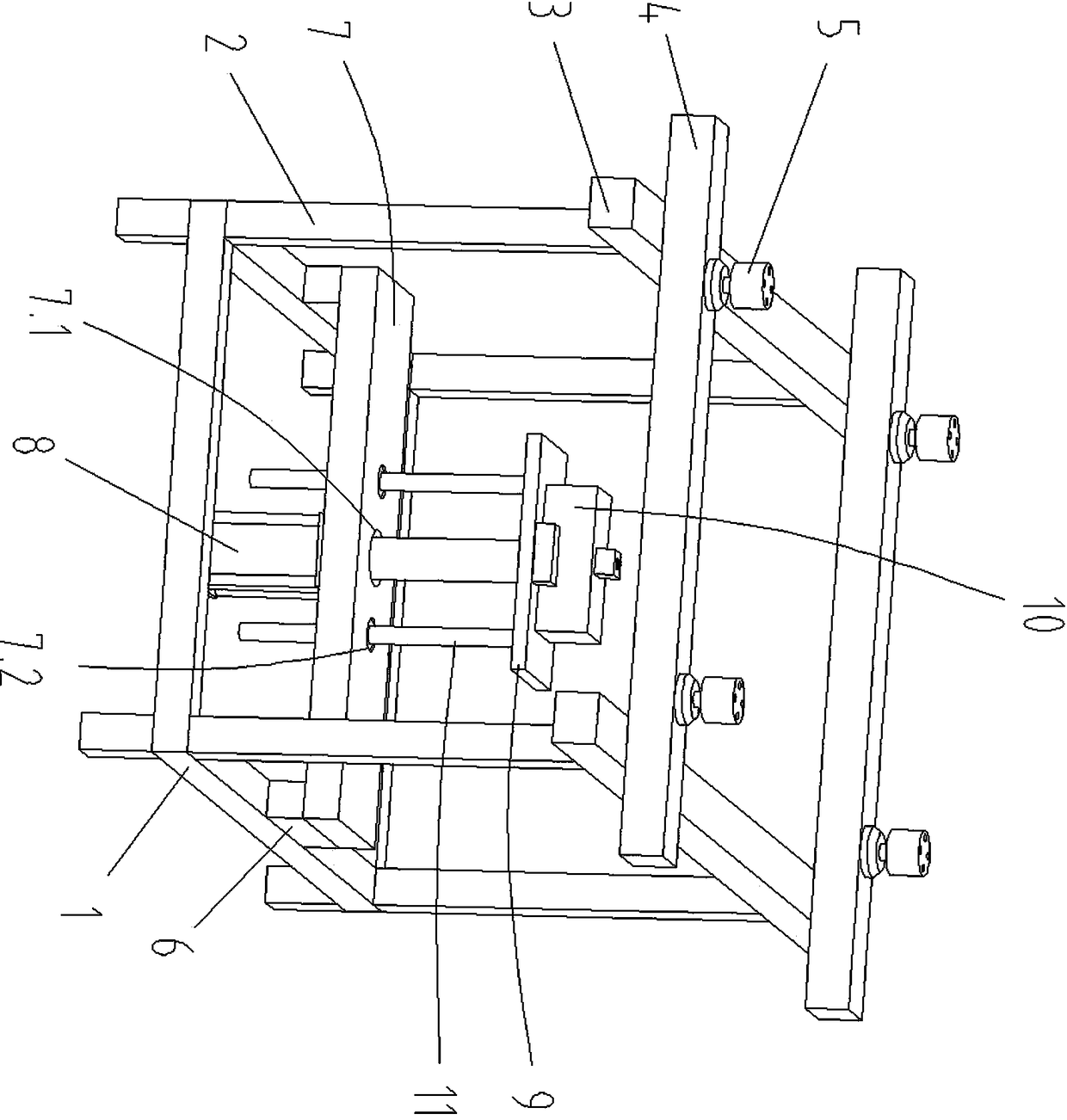

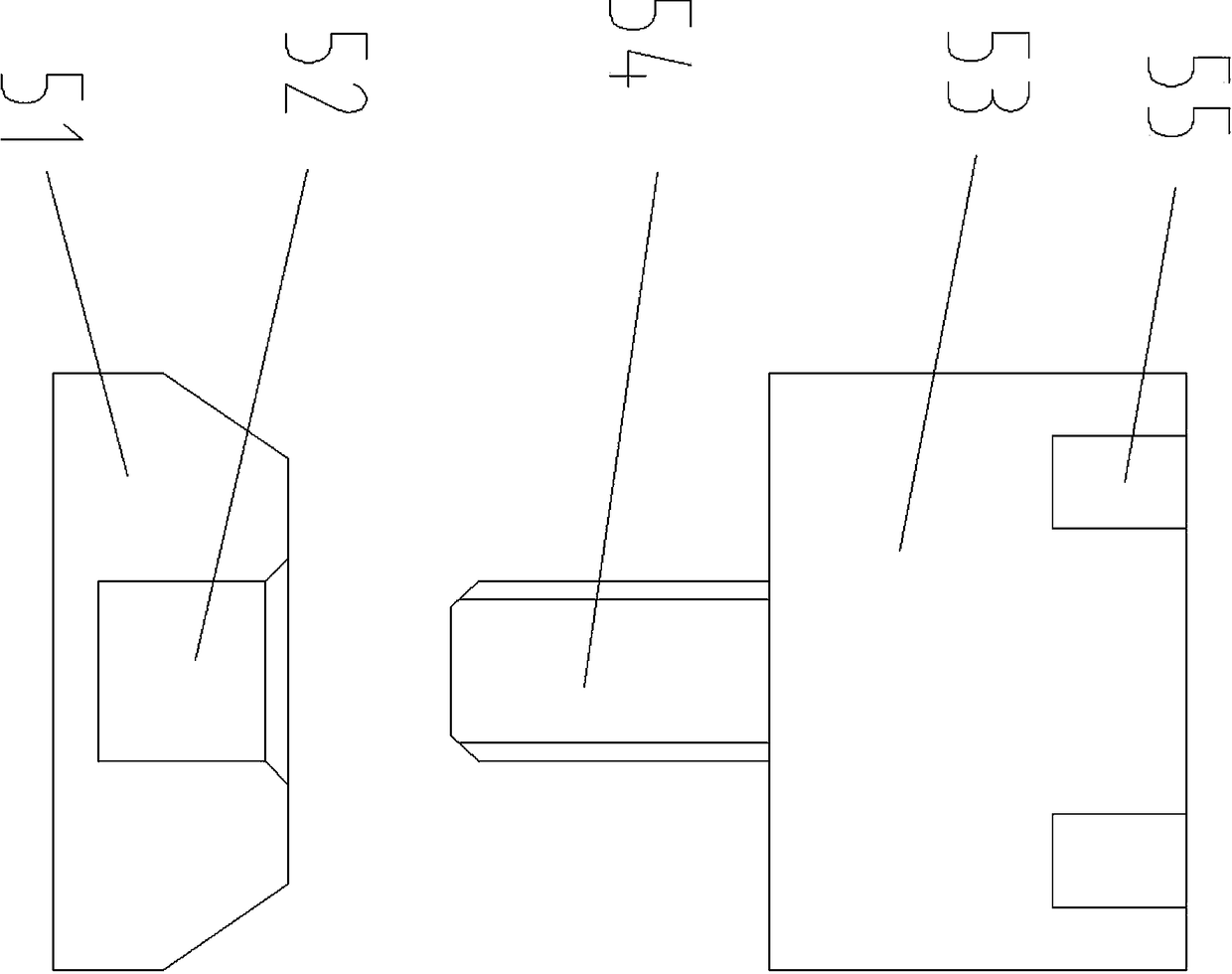

[0029] Among them, such as figure 1 and figure 2 As shown, the deflection measuring device includes a fram...

Embodiment 2

[0040] A method for testing the deflection of float glass, comprising the following steps:

[0041] Step 1. Cutting pattern: Select a 2.5mm thick float glass plate to be tested, and cut the float glass plate to be tested into a circular glass pattern with a specification of φ800mm.

[0042]Step 2. Pattern mark: Label paper is attached to the center point of the tin liquid surface and the center point of the air surface of the glass pattern, and the label paper corresponding to the center point of the tin liquid surface and the center point of the air surface of the glass pattern is used Paint a circle with a diameter of 3mm with a red marker. During the coating process, it must be applied evenly, and there must be no leakage of coating, so as to avoid the problem of inaccurate data caused by the transmission of infrared rays through the glass.

[0043] Step 3, zeroing the deflection measuring device: use a plate without deflection to zero the deflection rangefinder in the def...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com