Construction method of pervious rib type arch beam tunnel

A technique for tunnel construction and transparent ribs, which is applied in the construction of transparent ribbed arch beam tunnels and the field of construction of transparent ribbed arch beam tunnels. To achieve the effect of convenient construction, improving strength and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

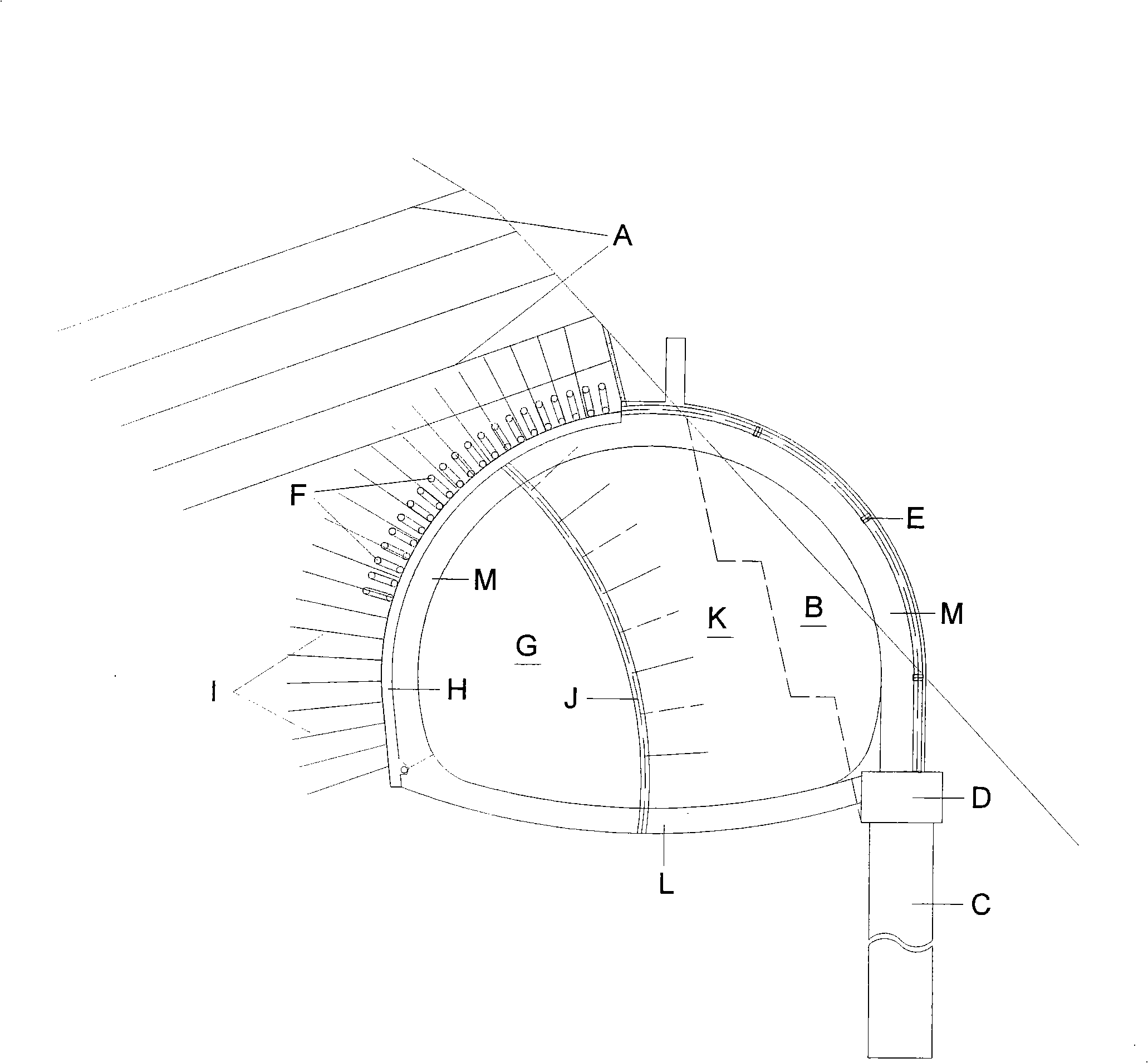

[0028] The present invention will be described in further detail below according to accompanying drawing:

[0029] according to figure 1 , the construction method and steps of the transparent ribbed arch beam tunnel are as follows:

[0030]A. Reinforcement of horizontal tube sheds on the vaulted hillside: Before excavation of the tunnel, 5 or 6 rows of horizontal tube sheds are arranged on the slope of the vaulted roof along the line, with a spacing of 2m×2m, arranged in a plum blossom shape, and each tube shed is Drill horizontally at an angle of 0° or 5° or 10° or 15° or 20° or 25°, the axis of the drilling hole is perpendicular to the direction of the line, and the pipe shed has an outer diameter of 108mm or 138mm and a wall thickness of 6mm or 8mm. Hot-rolled seamless steel pipe with a length of 15m or 18m or 20m. Two rows of grouting holes with a diameter of 20mm are drilled around the pipe wall. After the steel pipe is driven into the surrounding rock, a steel cage is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com