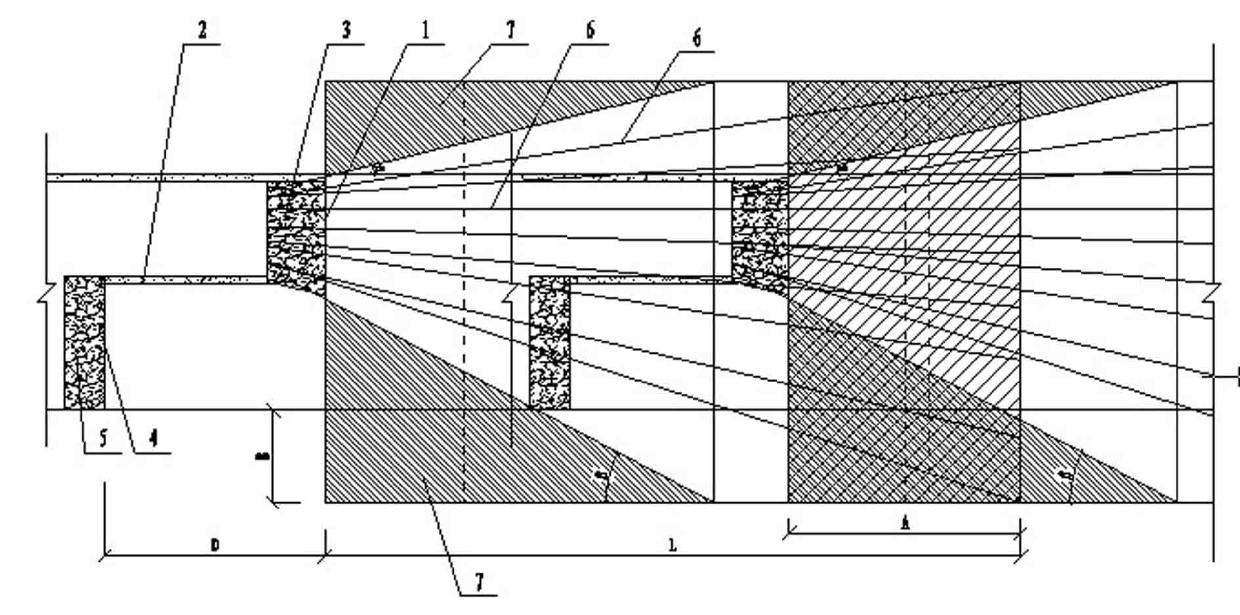

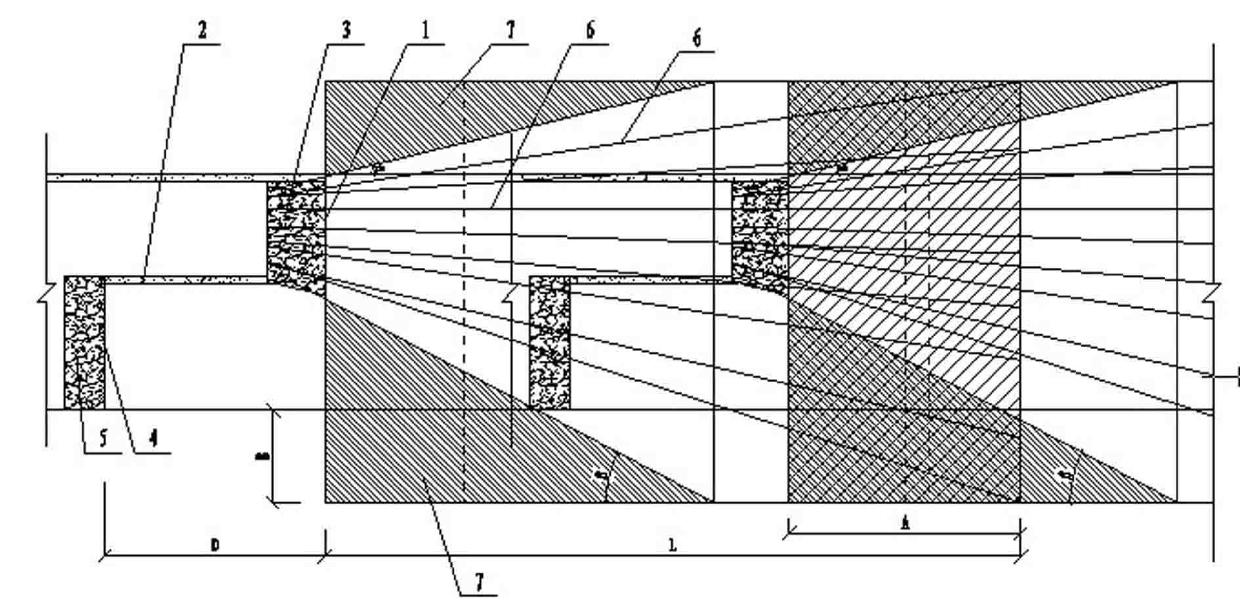

Method for constructing tunnel by finishing full section curtain grouting from upper-half section

A curtain grouting and tunnel construction technology, applied in tunnels, tunnel linings, earthwork drilling, etc., can solve the problems of difficult construction, long construction period, unsafe construction, etc., to shorten the construction period, reduce construction difficulty, and ensure construction. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] List the following engineering examples to further illustrate the grouting method of the present invention:

[0029] 1. Project introduction:

[0030] The Qiyueshan super-long tunnel is located 23km north of the west of Lichuan City, Hubei Province. It starts from Leyuangou, the wild tea township in the east, and crosses Qiyueshan and Jingzhuyuan in the northwest. It exits at Xiazhenzui in Baizhanggou. , the exit mileage is DK371+778, the total length is 10523m, the maximum buried depth of the cave body is 670m, and the whole cave is drained from one side. The geological structures traversed by the tunnel are the Qiyueshan anticline and the Jianzhuxi syncline. The geological conditions are extremely complex, and they are the key and controlling projects of the whole line. The tunnel passes through about 4.7km of soluble rock in the formation, accounting for 45% of the tunnel length. The main engineering geological problems include: karst and karst high-pressure water i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com