Small-bore long distance curved pipe jacking method

A small-caliber, curved technology, applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as traffic obstruction, and achieve high social benefits, less damage, and less man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

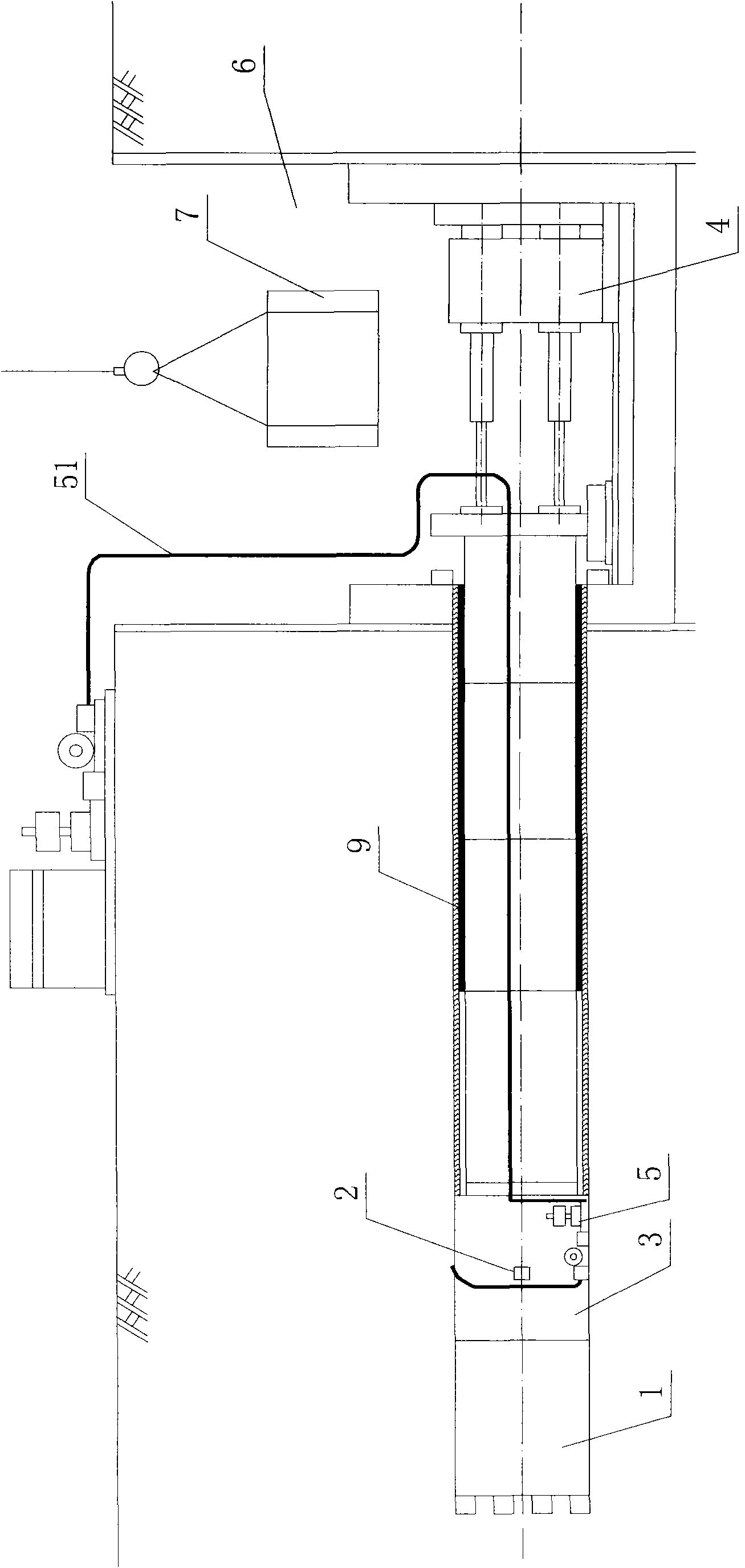

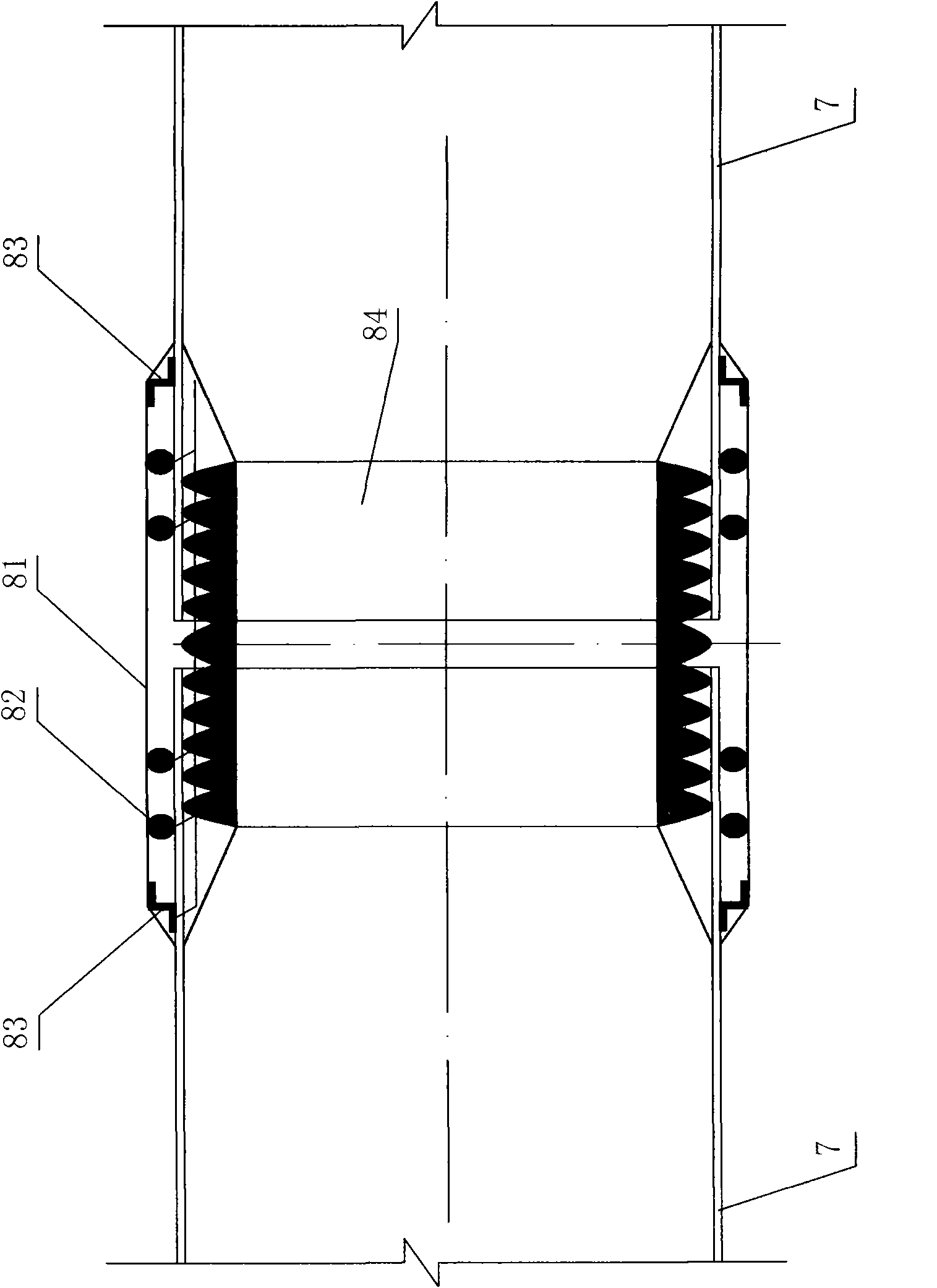

[0057] Example 1. The sewage pipeline project of the east section of Xinchangjiang City

[0058] The sewage pipeline project of the east section of the Xinchang River City is mainly to collect the industrial sewage from the Xinchang County Pharmaceutical Factory, Xinhecheng Co., Ltd. and other enterprises in the east section of Xinchang County to the proposed Ru'ao Town sewage treatment plant through the sewage pipeline of this project. Because this sewage pipeline project needs to continuously cross the Xinchang River and the factory block along the river at stake K2+080~K3+100, and this crossing section is to ensure the stability and safety of the original building, at the intersection of stake K2+ A circular curve with a radius of 1500m (L-607.055m, a=23°11′16″) is set at 384.676.

[0059] The construction of this project started in July 2007 and was completed for acceptance in February 2008. The design sewage pipe diameter is The steel pipes are buried deep and 16 meters thic...

example 2

[0067] Example 2. Sewage treatment project of Pudong Road, Pukou District, Nanjing City

[0068] The sewage treatment project of Pudong Road, Pukou District, Nanjing is a major water environment construction project in Nanjing, which is subordinate to the main sewage treatment project. The project is located in a prosperous business district of the city. The sewage pipelines mainly run along the busy Pudong Road. The underground pipelines are intricate and complex, including gas pipelines, water pipelines, communication pipelines, and fire-fighting pipelines. There are dense buildings along the line, and there is a 220kV underground high-voltage cable. The construction method of sewage pipeline is pipe jacking, the total length of the pipeline is 1085m, and the pipe diameter is For steel pipes, the elevation of the bottom of the top pipe is -5.00-6.00m, and the buried depth is 9.42-11.25m. Among them, the radius of curvature of the curve jacking pipe is 900m, and the total leng...

example 3

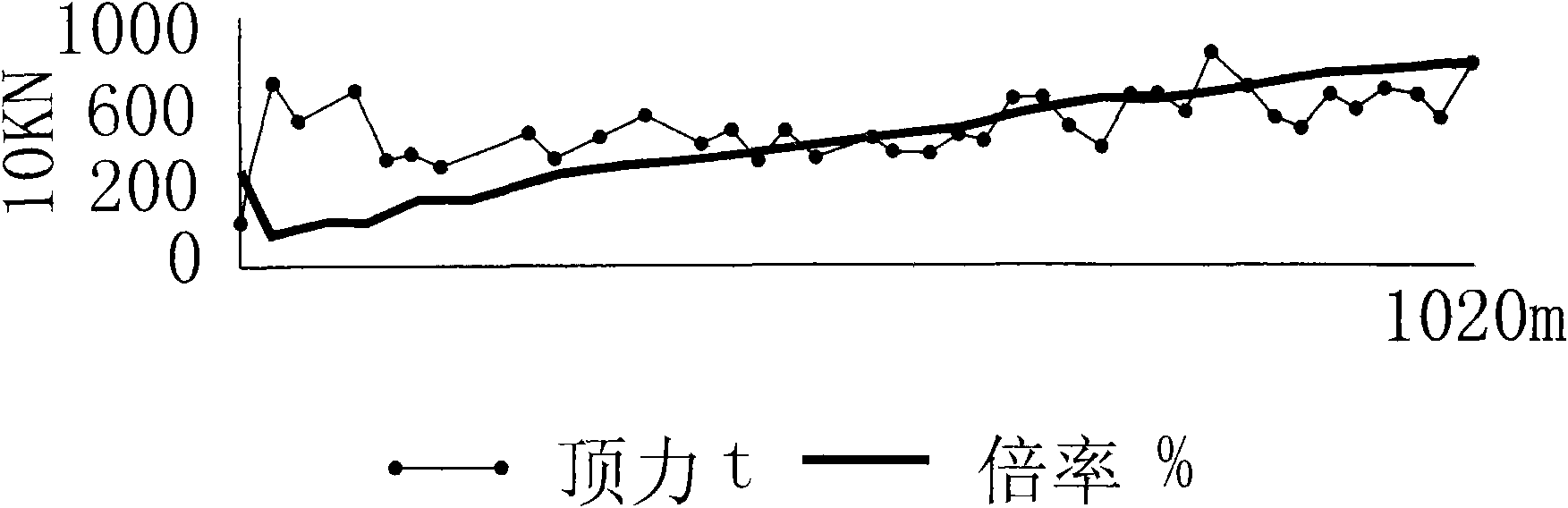

[0082] Example 3. Road and sewage pipeline project of Changchun Road, Wuhu Economic and Technological Development Zone

[0083] The road and sewage pipeline project of Changchun Road in Wuhu Economic and Technological Development Zone is located on Changchun Road with heavy traffic. It is close to North Changjiang Road, with Shunchang Industry and Trade Company, Beitong Chery Planning and Design Institute and Chery Automobile Co., Ltd. in the west, Pujiang Road, Yinhu North Road, and Zhujiang Road to the east, Guoxin Hotel, Dajiang Automotive Electronics Company, Enterprise companies such as Knauf Gypsum Board Company and Xinke New Material Company have a large traffic flow, and saving construction time is the best social benefit. Therefore, this project adopts the curved pipe jacking construction technique for the main sewage pipeline of Pujiang Road-Zhujiang Road. Design sewage pipe diameter of this section The steel pipe has a total length of 1020m, among which a circular cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com