High altitude suspension selecting bulk construction method of barrel shell type bolt ball node network frame

A construction method and the technology of bolt balls, which are applied in the direction of construction and building construction, etc., can solve the problems of erecting rod materials and long working site time, high cost of pipe truss structures, and high requirements for scaffolding erection, so as to facilitate construction organization and shorten construction period , The effect of increased construction flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In conjunction with accompanying drawing, concrete construction method of the present invention is as follows:

[0021] 1. Measure and set out the elevation and axis of the embedded parts supporting the top surface.

[0022] 2. Balls and rods are all manufactured in the factory, and re-inspected after entering the field. The materials, specifications, dimensions, and serial numbers meet the design requirements.

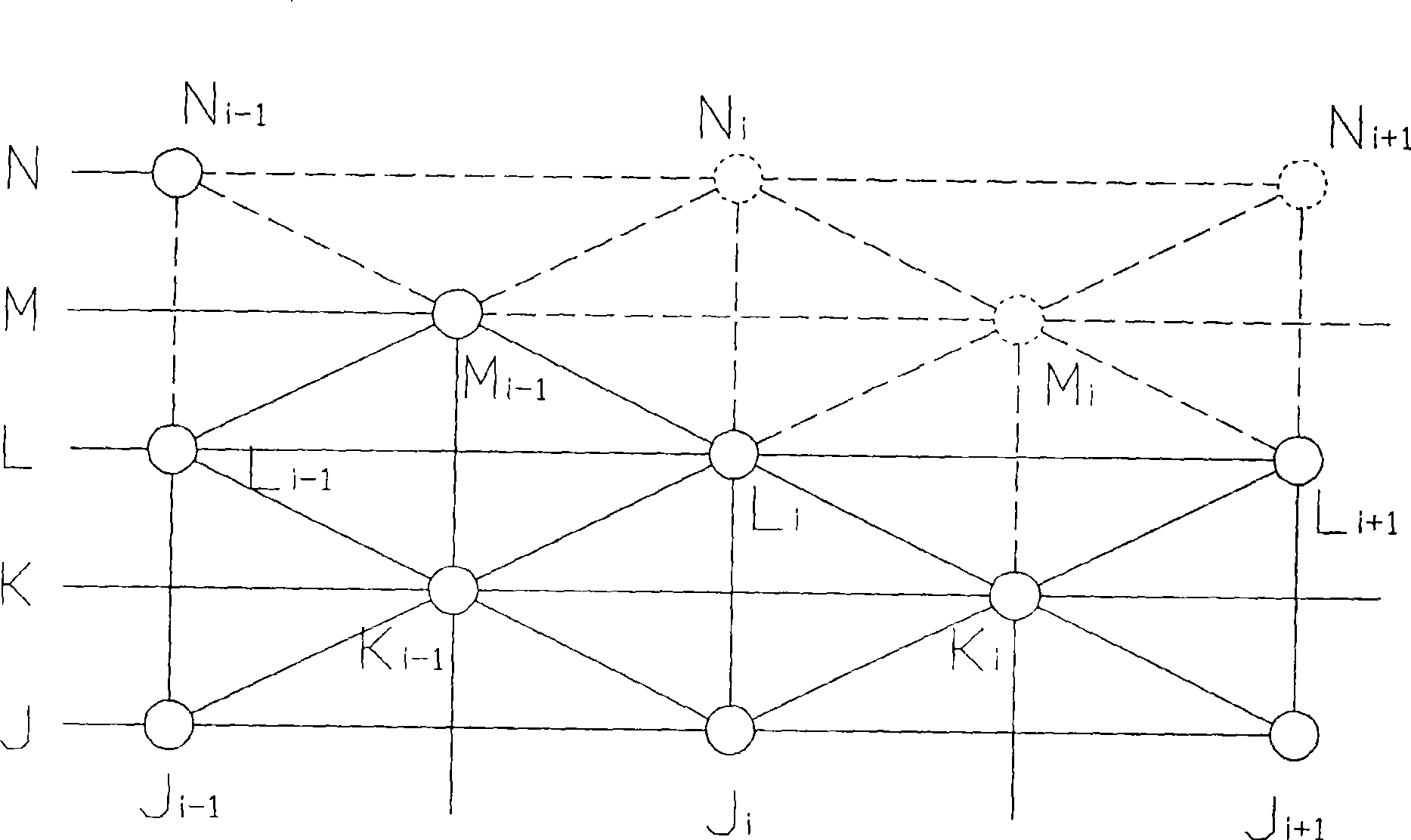

[0023] 3. Combined with the support situation along the longitudinal direction, the cylindrical shell-type bolt ball joint grid is divided into several rings, and the span of each ring is the same as the design span of the grid. Combined with the site conditions, steel pipe scaffolding is erected in a ring belt, and the bearing capacity of the scaffold is required to meet the requirements of the bulk reticulated shell of the ring belt, and the calculation and construction of vertical bars and horizontal bars meet the requirements of current specifications.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com