Method and equipment for mounting precast beam

A technology of prefabricated beams and equipment, applied in bridge construction, erection/assembly of bridges, bridges, etc., can solve the problems of inability to meet the requirements of bridge construction, inability to complete the installation of prefabricated beams, low construction costs, etc., and achieve high construction efficiency and structural The effect of simplicity and short installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

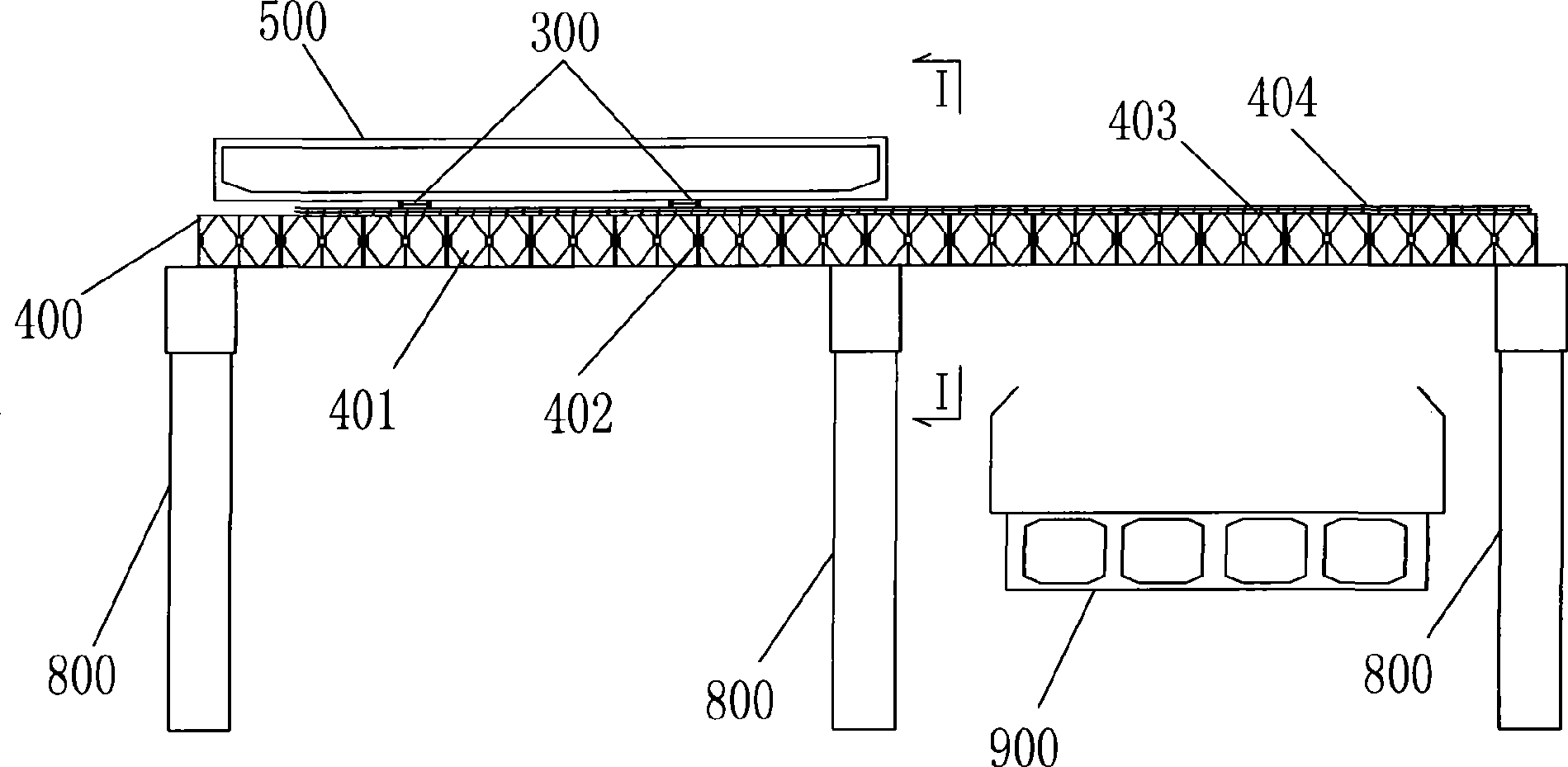

[0025] In order to make the present invention easier to understand, the present invention will be further explained below in conjunction with the accompanying drawings, but the embodiments in the accompanying drawings do not constitute any limitation to the present invention.

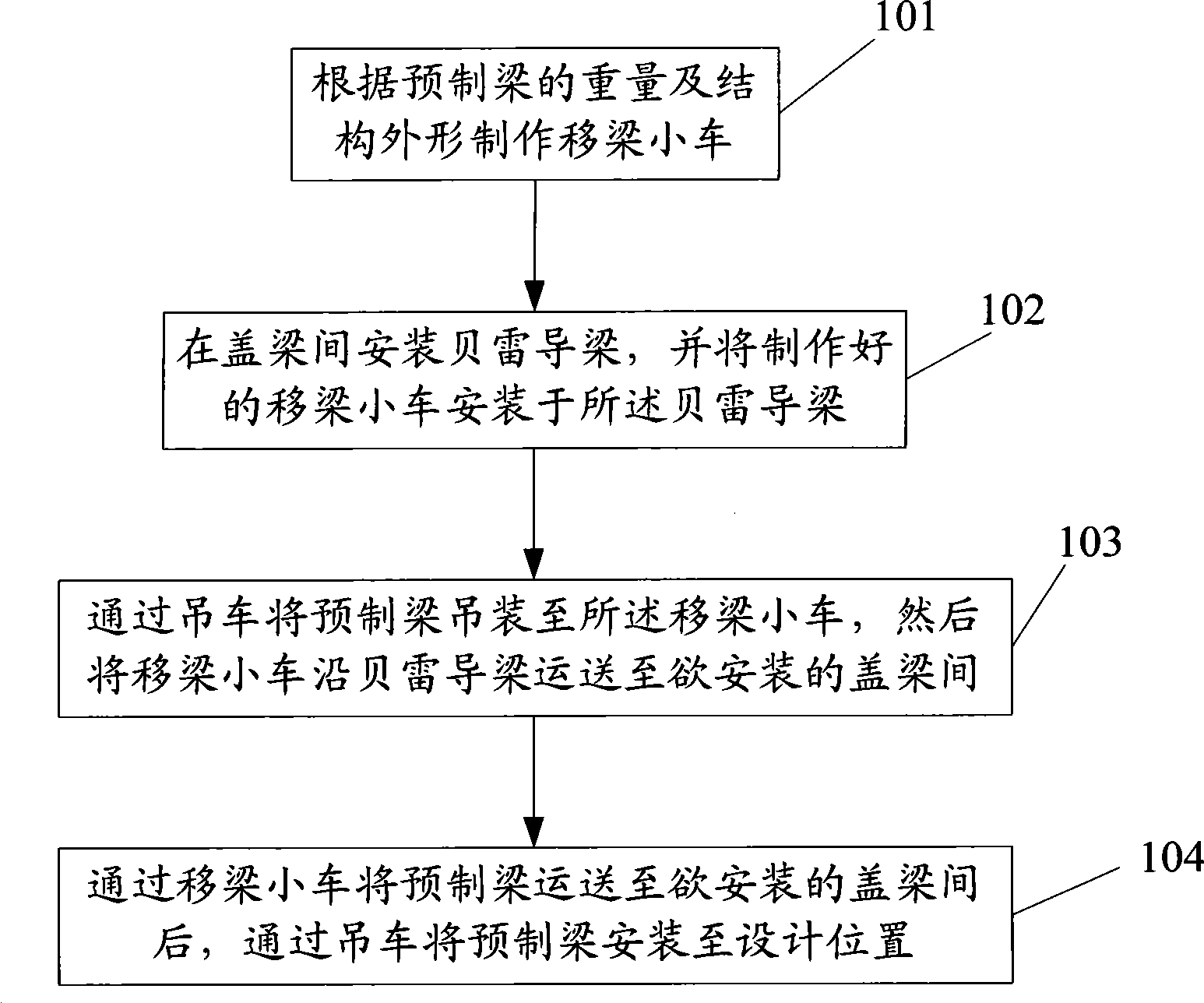

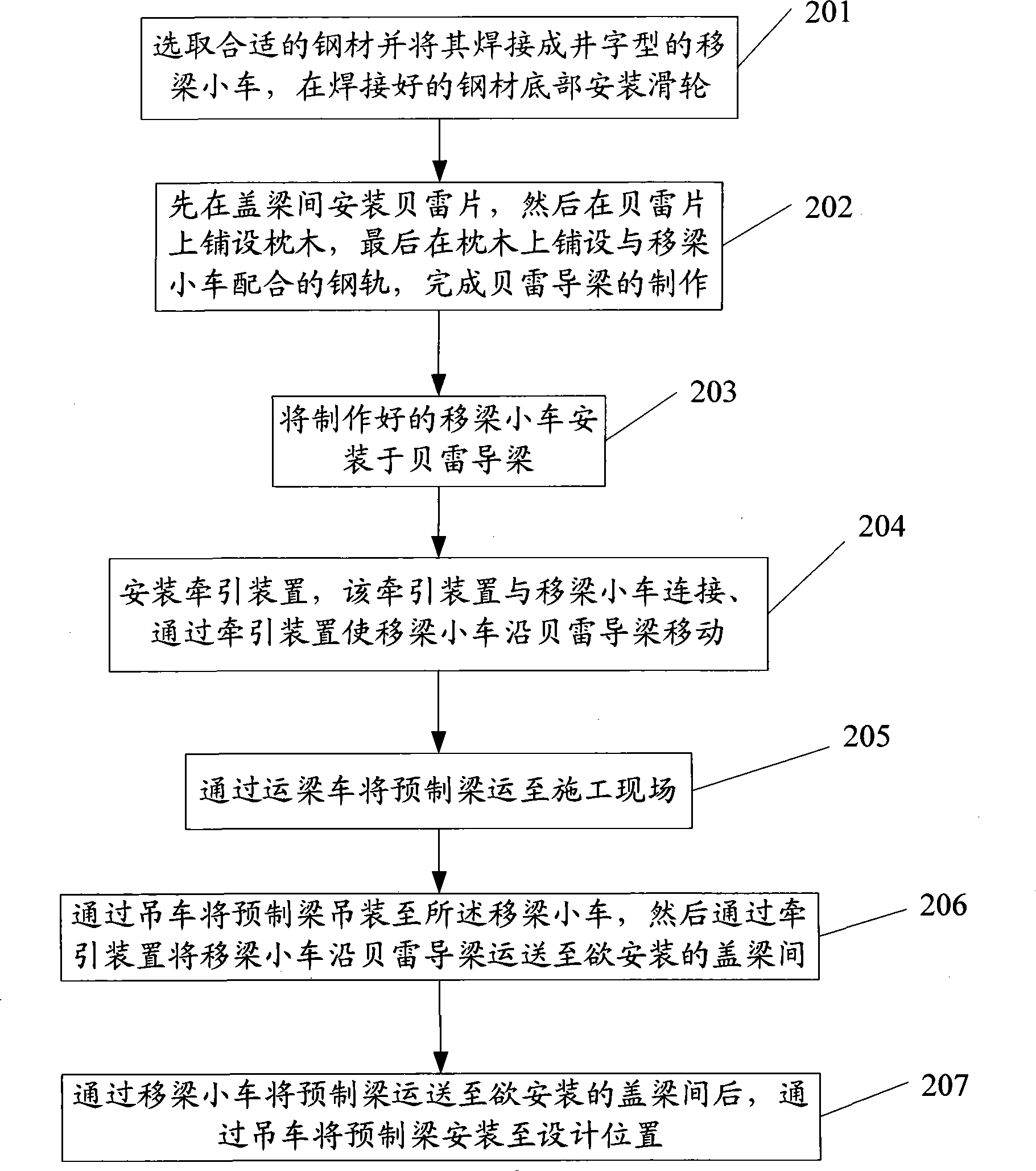

[0026] Such as figure 1 As shown, the first embodiment of the present invention provides a method for installing a precast beam, which is used to install a precast beam on a bridge cover beam that spans an old bridge or other obstacles, including the following steps:

[0027] 101. Make a beam-moving trolley according to the weight and structural shape of the precast beam;

[0028] 102. Install Bailey guide beams between the cover beams, and install the manufactured beam-moving trolley on the Bailey guide beams;

[0029] 103. Hoist the precast beam to the beam-moving trolley by a crane, and then transport the beam-moving trolley along the Bailey guide beam to the cover beam room to be installed;

[0030] 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com