Patents

Literature

31results about How to "Reliable friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

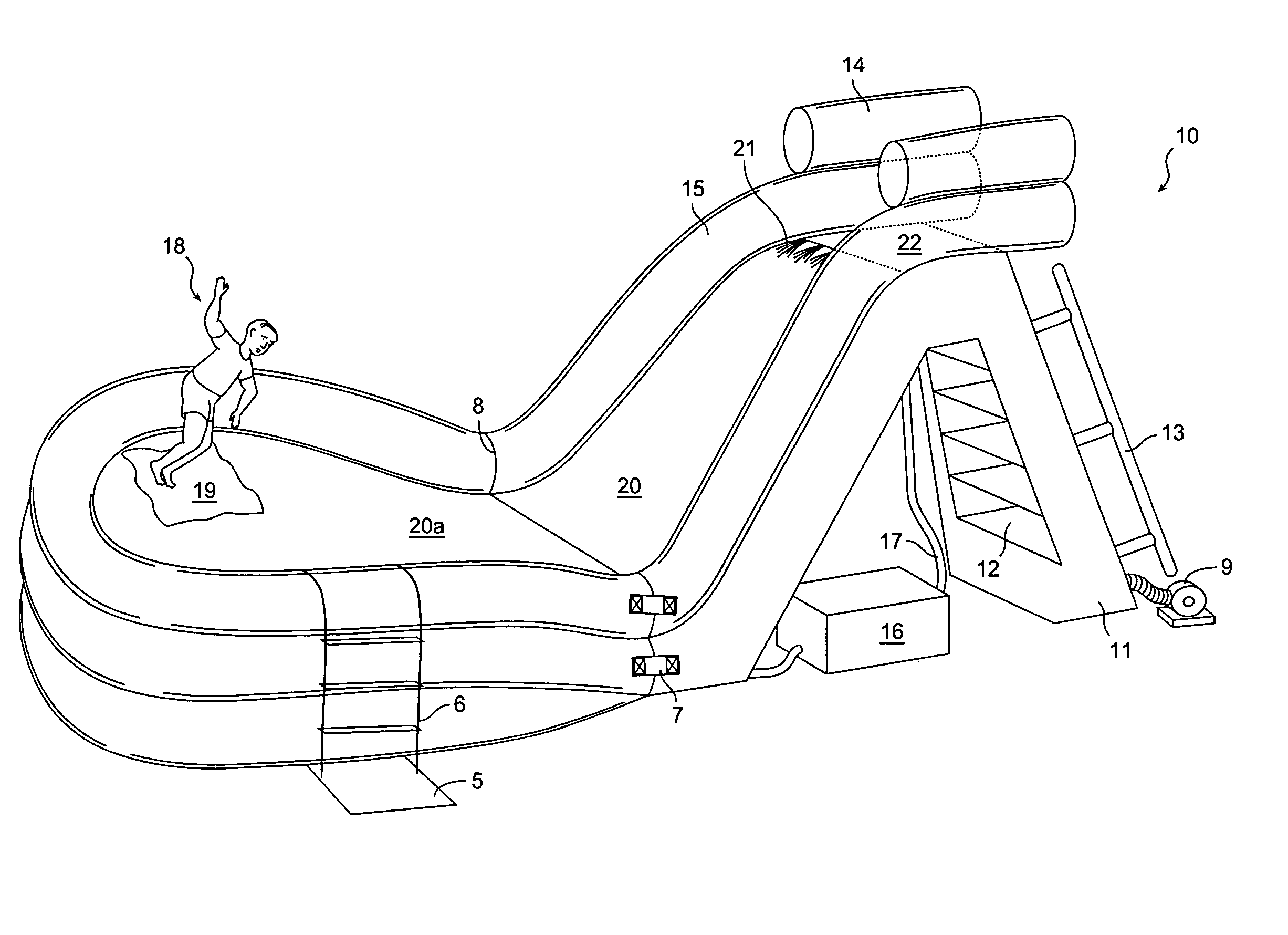

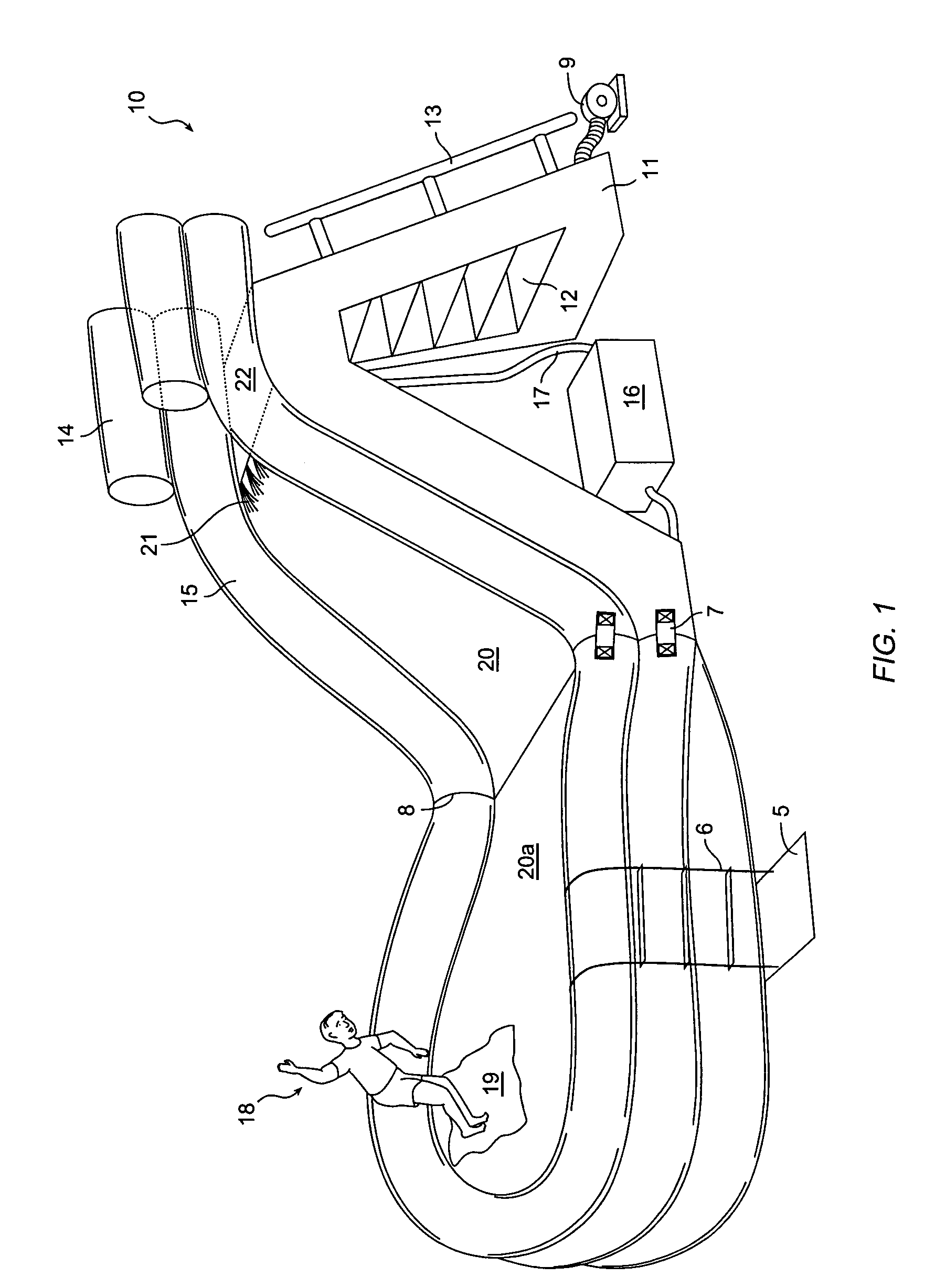

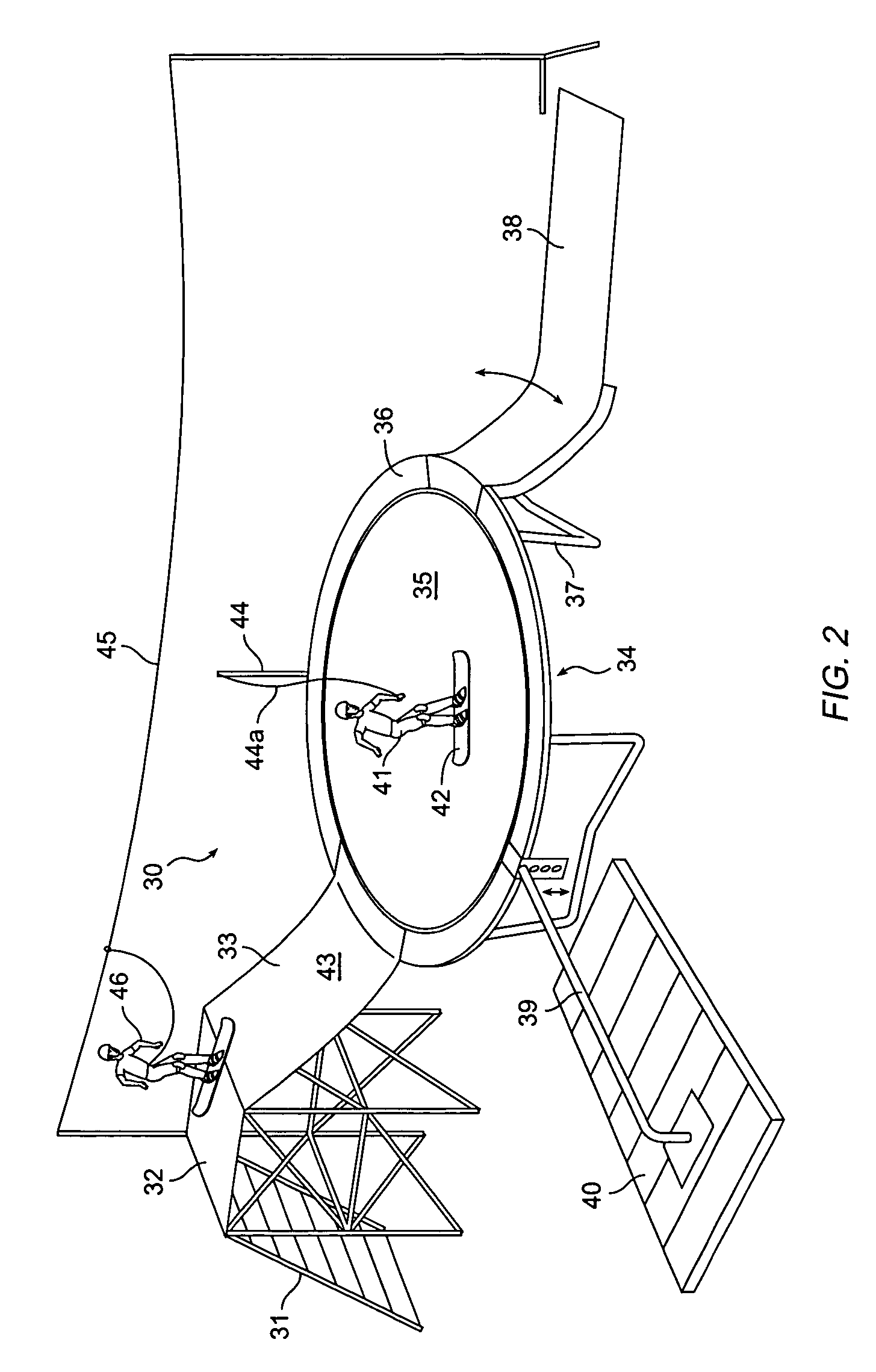

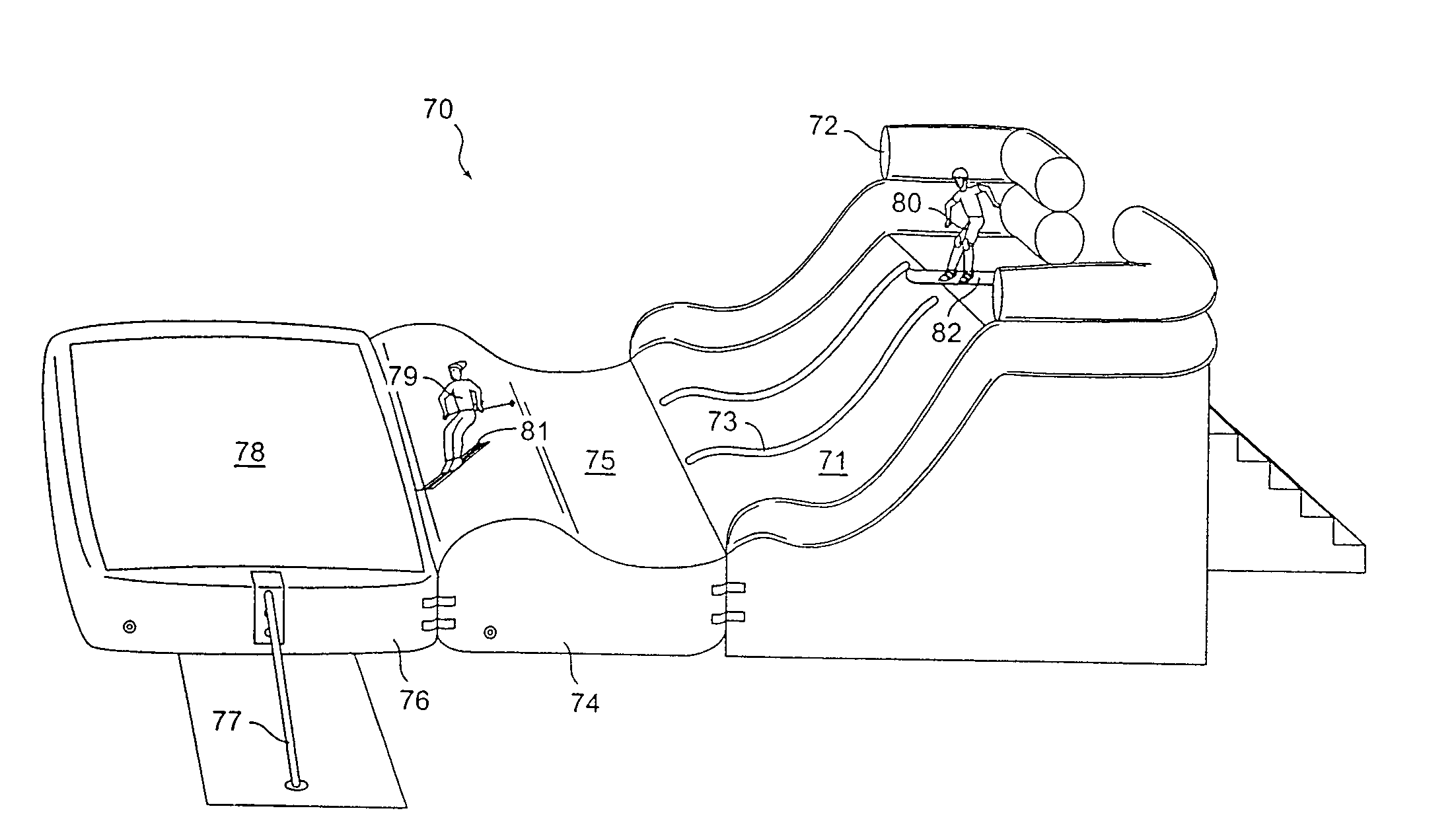

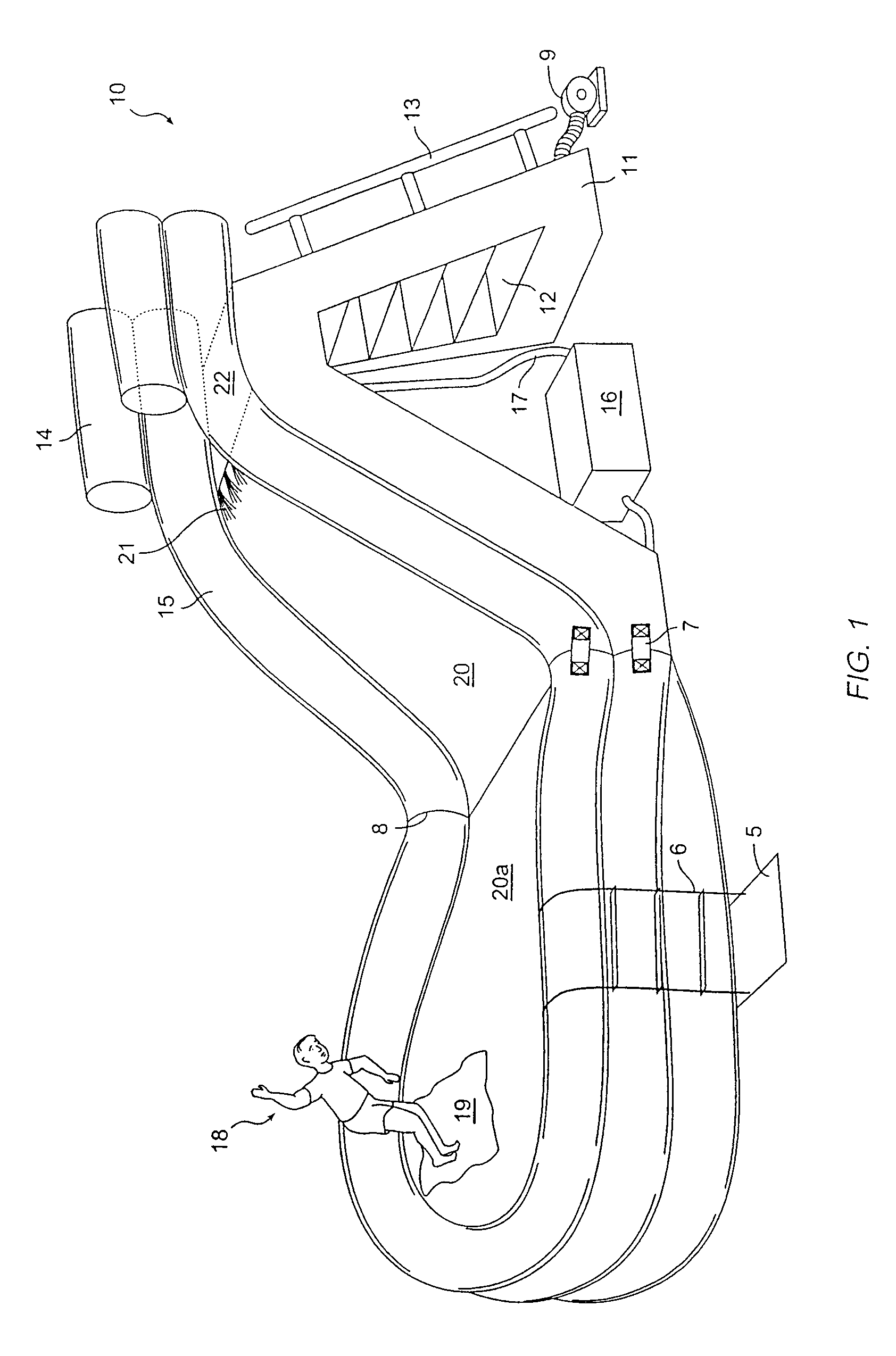

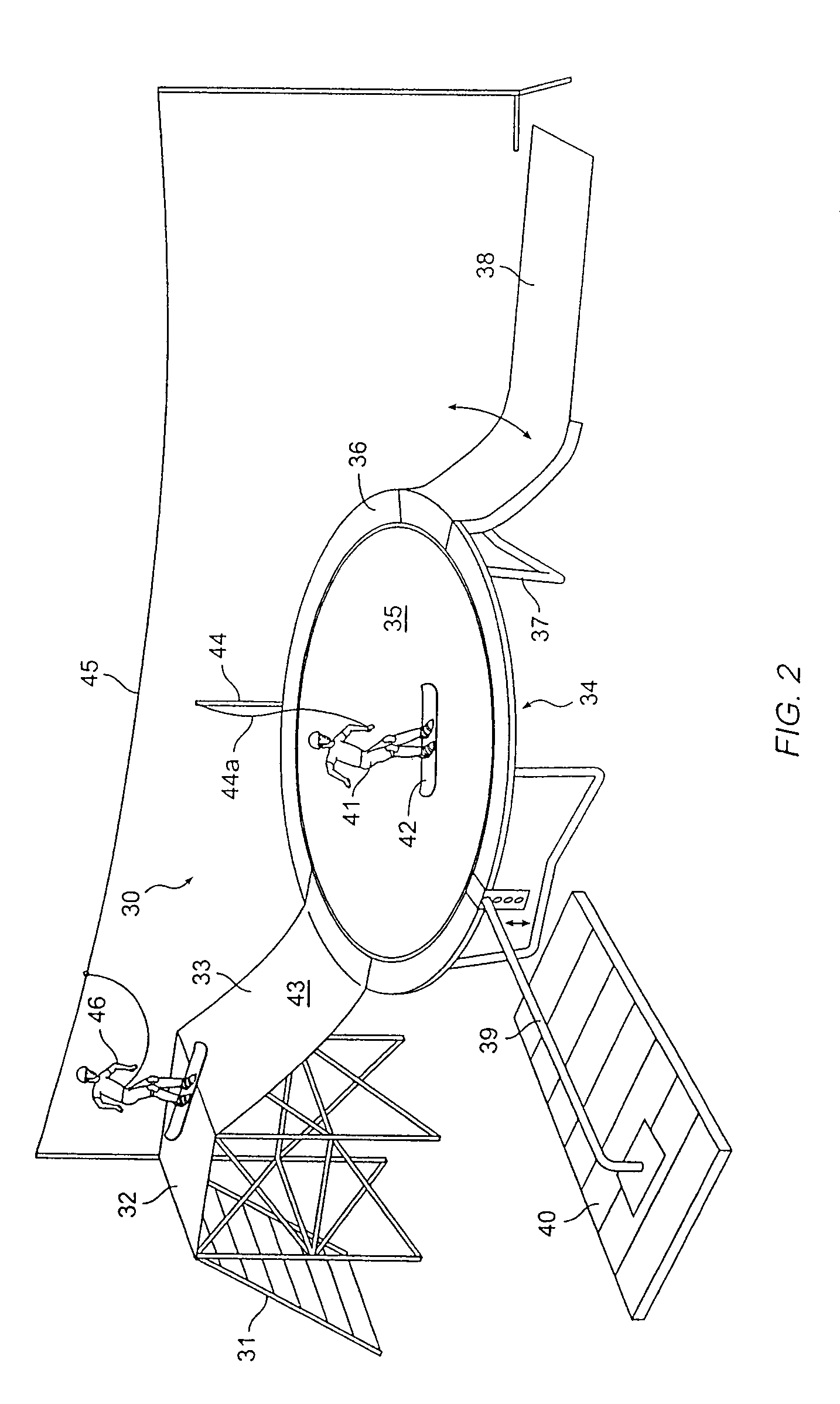

Sliding exercise apparatus and recreational device

InactiveUS7309302B1Improve experienceSufficient sizeSki bindingsGymnastic climbingEngineeringExercise machine

A sliding exercise apparatus and recreational device which can be employed both wet and dry. A user can traverse the device which includes a surface which can be inclined as a durable low friction sheeting material. The user can be supported by a wide variety of vehicles including sports boards and clothing apparel which, in turn, have a durable low friction layer for contacting the sliding exercise apparatus and recreational device for entertainment and in order to enhance gymnastic and board skills.

Owner:WORLDSLIDE

Sliding exercise apparatus and recreational device

InactiveUS7789804B1Improve experienceSufficient sizeSki bindingsGymnastic climbingEngineeringExercise machine

A sliding exercise apparatus and recreational device which can be employed both wet and dry. A user can traverse the device which includes a surface which can be inclined as a durable low friction sheeting material. The user can be supported by a wide variety of vehicles including sports boards and clothing apparel which, in turn, have a durable low friction layer for contacting the sliding exercise apparatus and recreational device for entertainment and in order to enhance gymnastic and board skills.

Owner:WORLDSLIDE

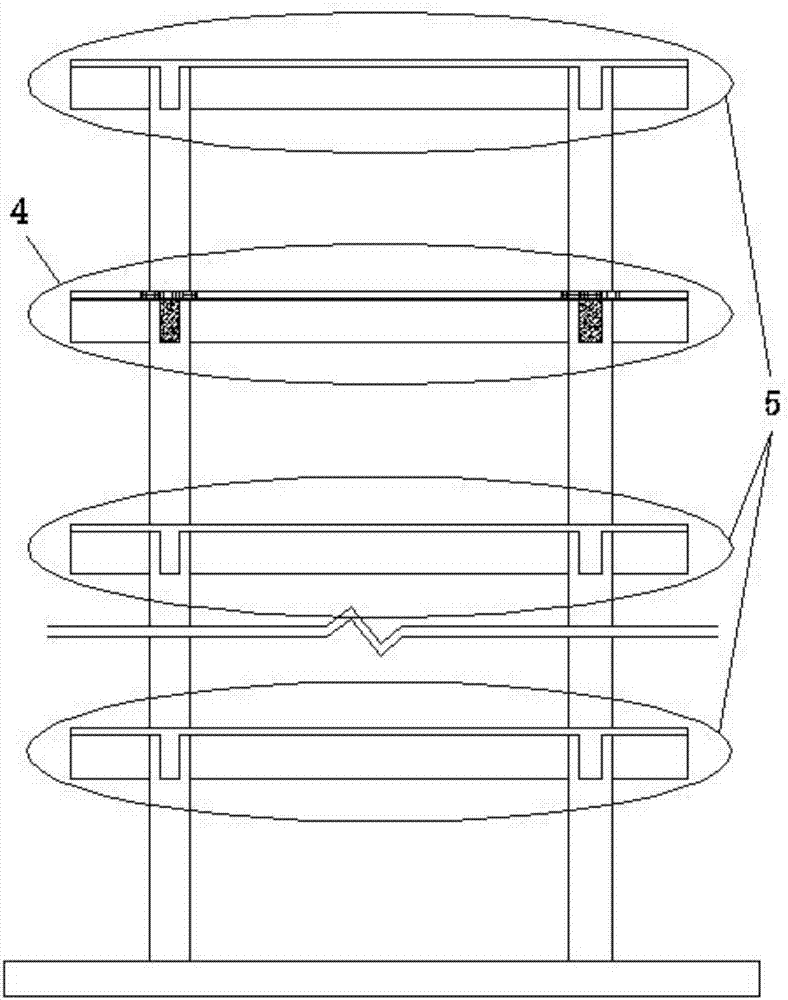

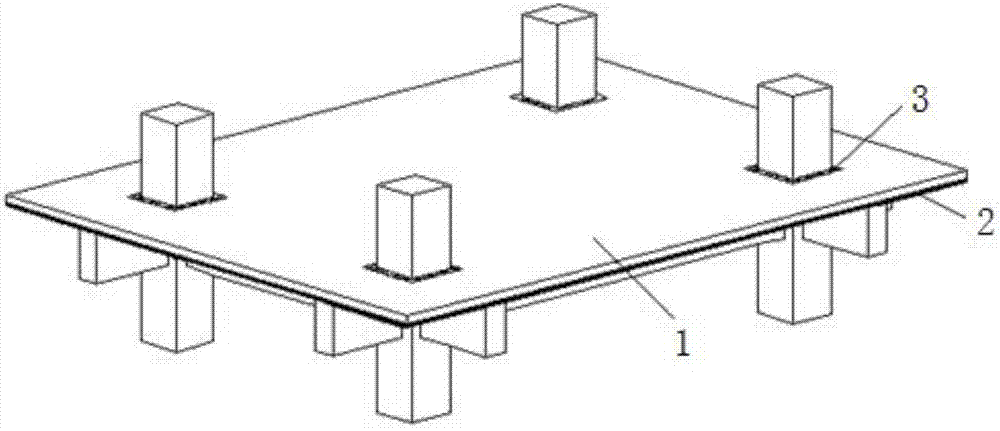

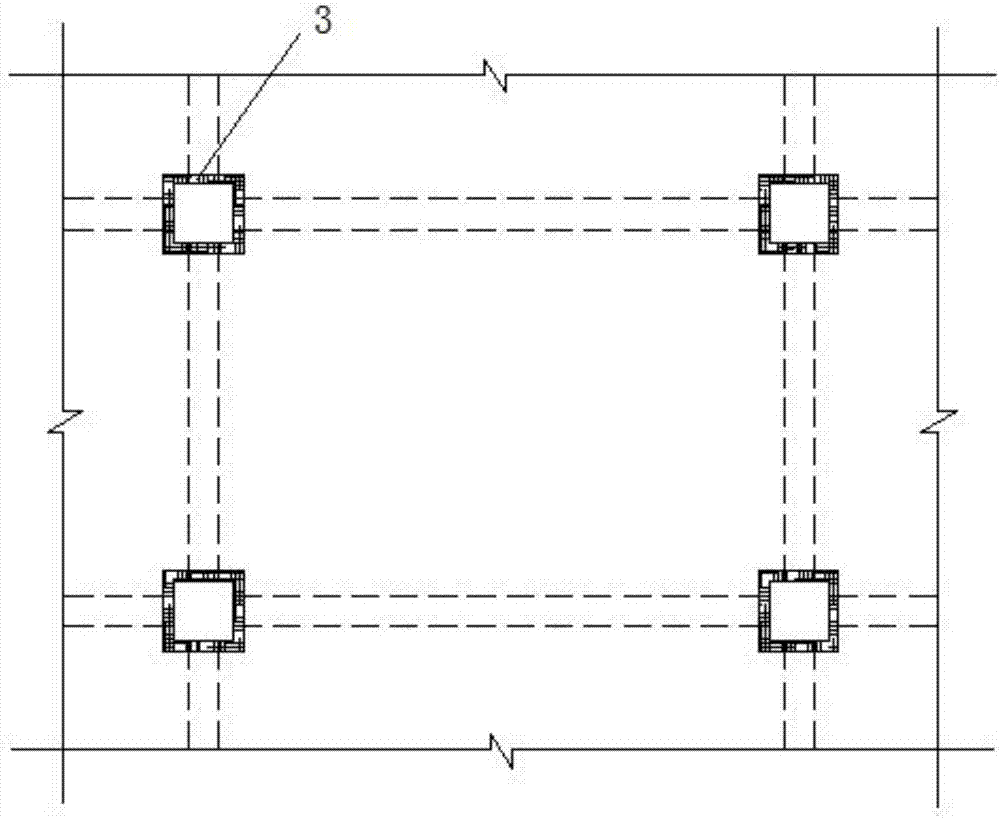

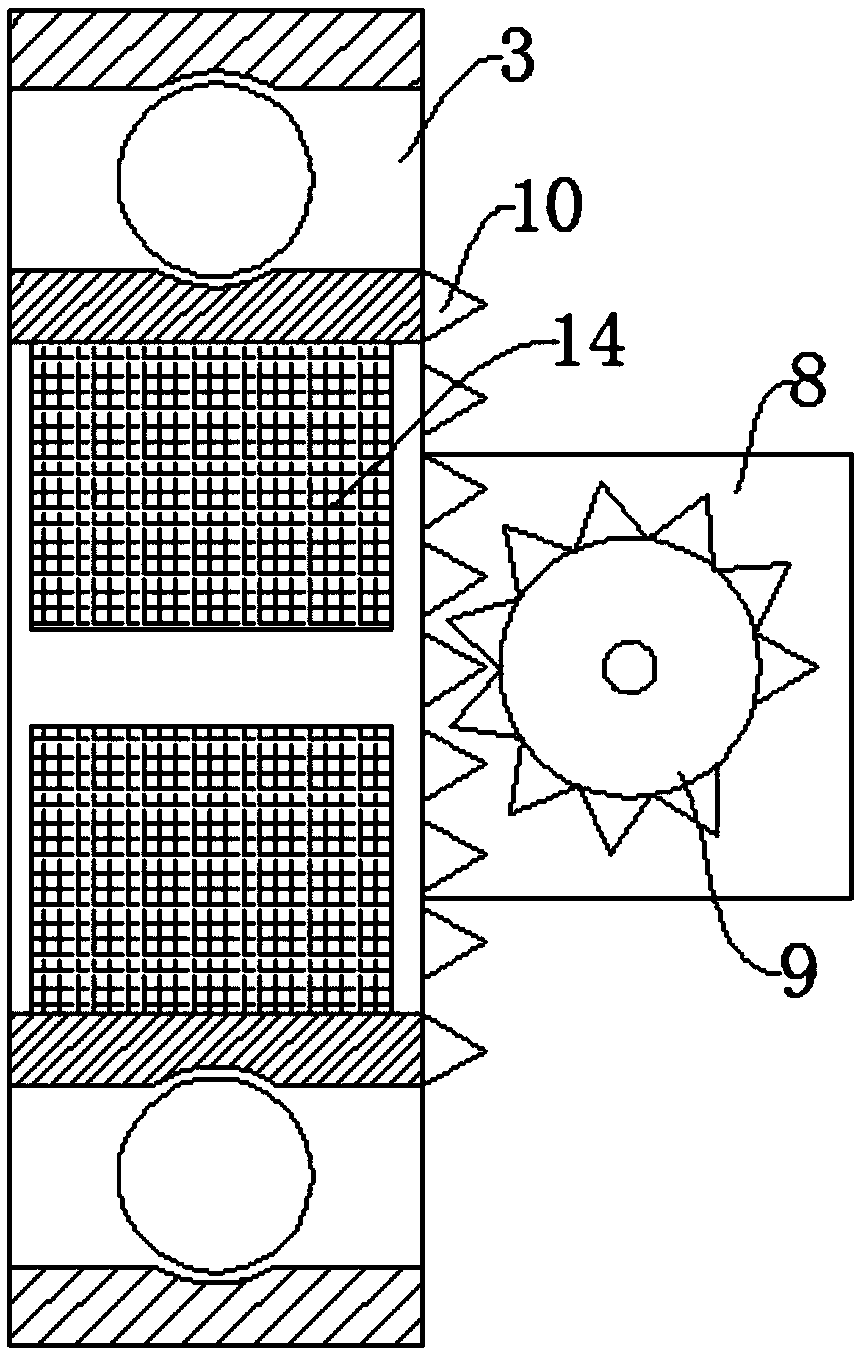

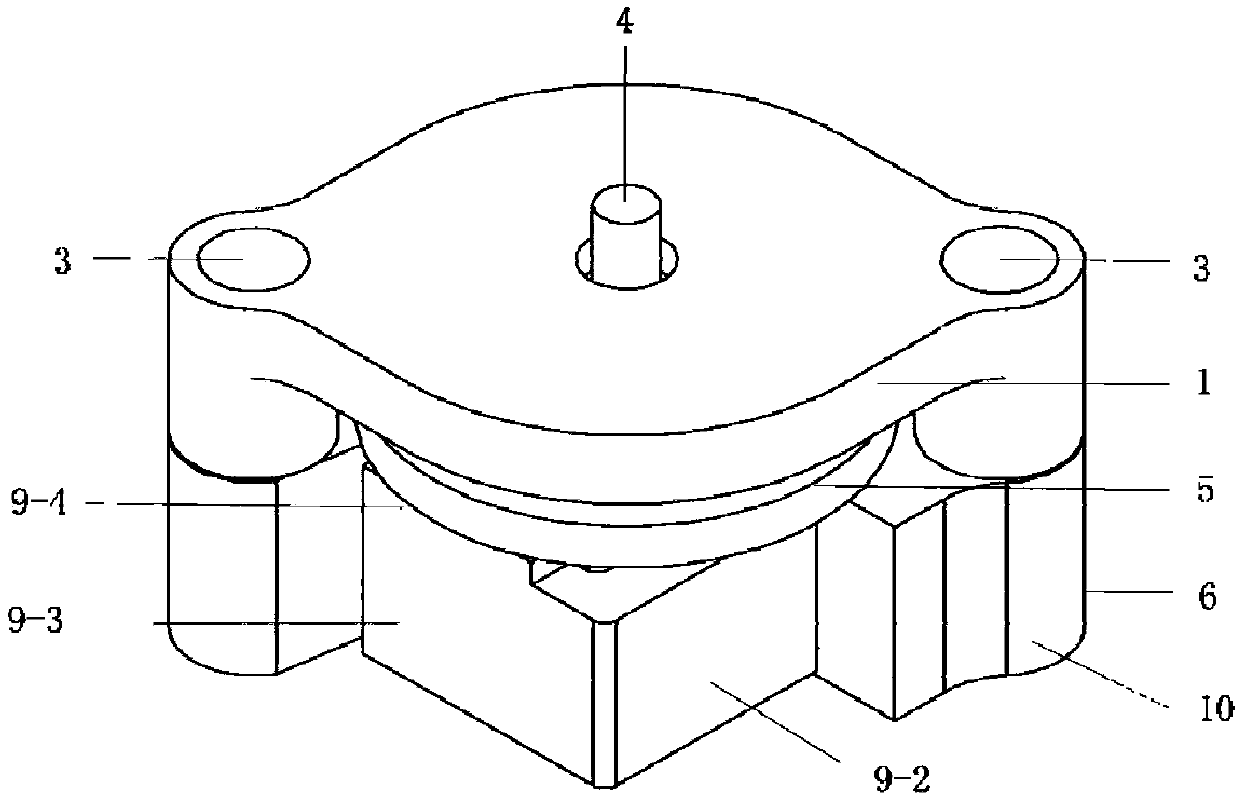

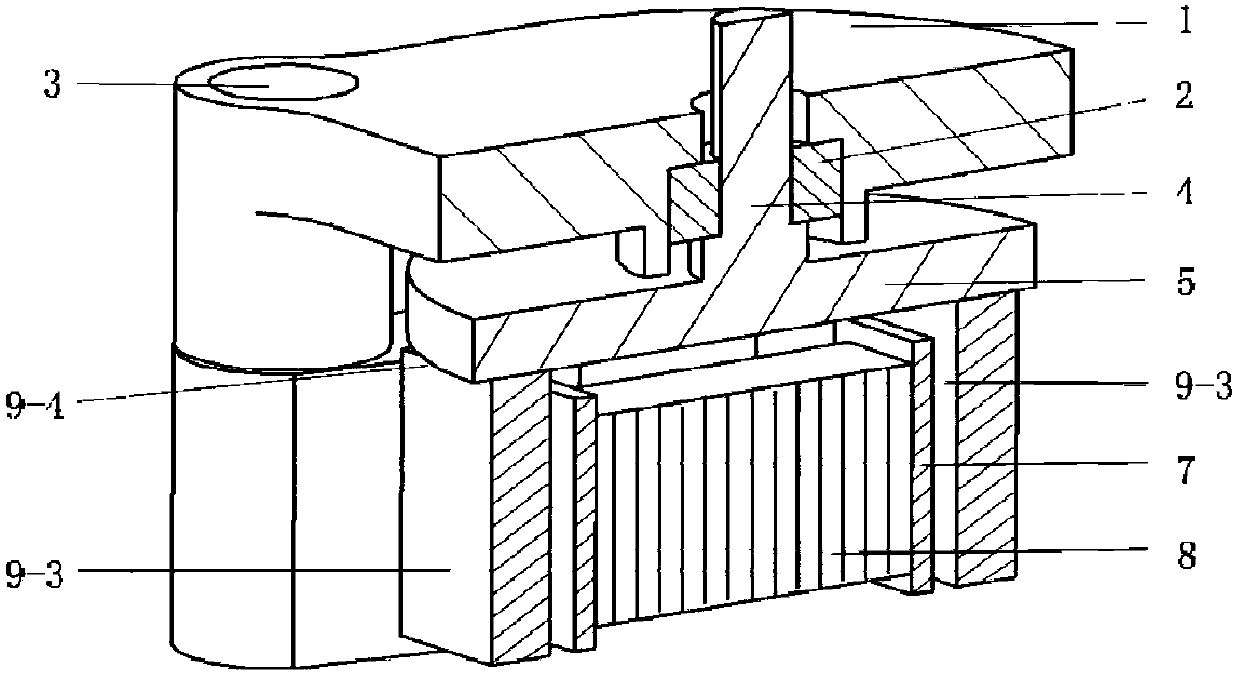

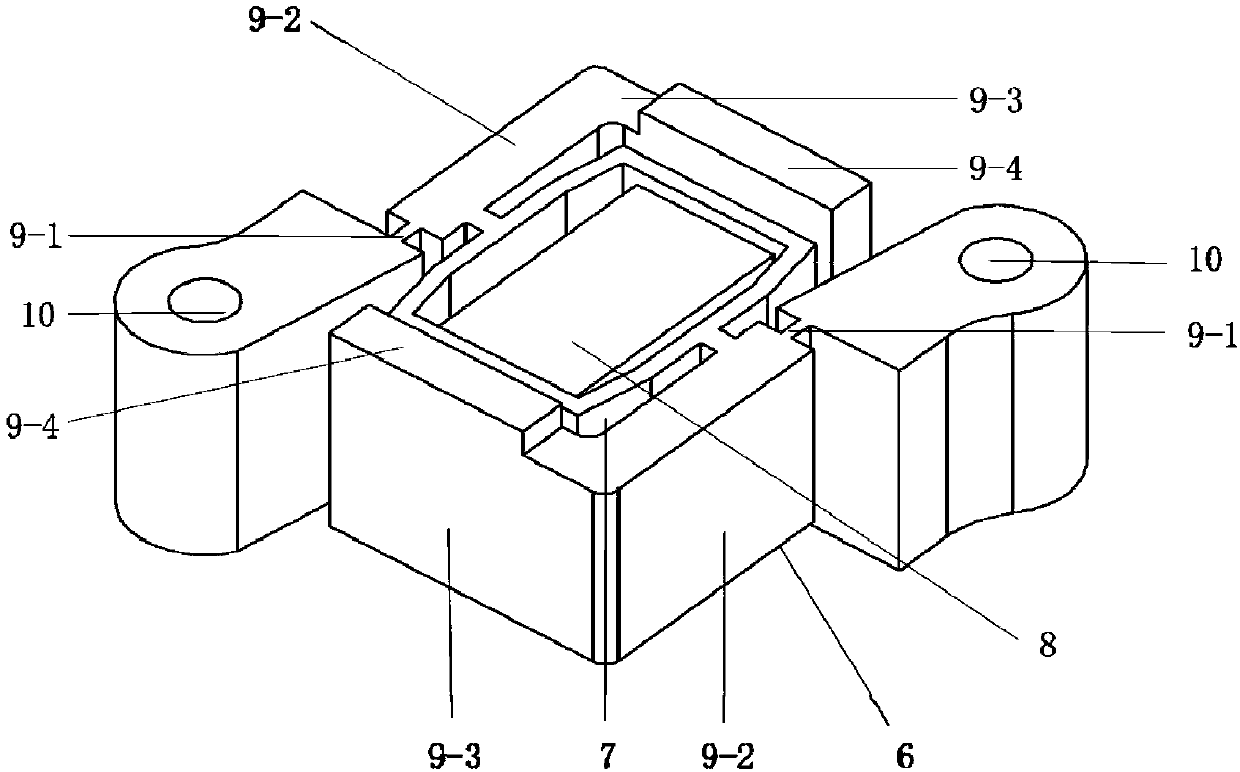

System for achieving structural shock absorption through floor slippage

InactiveCN107060126AReliable frictionAvoid collisionProtective buildings/sheltersShock proofingCushioningFloor slab

The present invention provides a system for structural damping by using floor slippage when the structure encounters a rare earthquake, including a damping layer floor, a frictional damping layer and an elastic buffer device; the frictional damping layer is laid on the The lower part of the floor slab of the friction damping layer is integrally poured together with the frame beam and frame column of the friction damping layer; the elastic buffer device is installed at the junction of the floor slab of the damping layer with the column body and the ring beam. The floor of the shock-absorbing floor is a part of the main structure, and it is converted into a shock-absorbing mass, which avoids adding too much mass to the main structure, and is easier to implement, eliminating the need to add hundreds of tons or even thousands of tons of mass blocks. Structurally, the possibility of increasing the vertical bearing load of the structure; laying the friction damping layer on the bottom layer can provide reliable friction for the damping layer floor, and the construction is simple and easy to implement; through the design of a reasonable elastic buffer device, shock absorption can be avoided The first floor slab collides with the main structure during the sliding process.

Owner:HUAQIAO UNIVERSITY

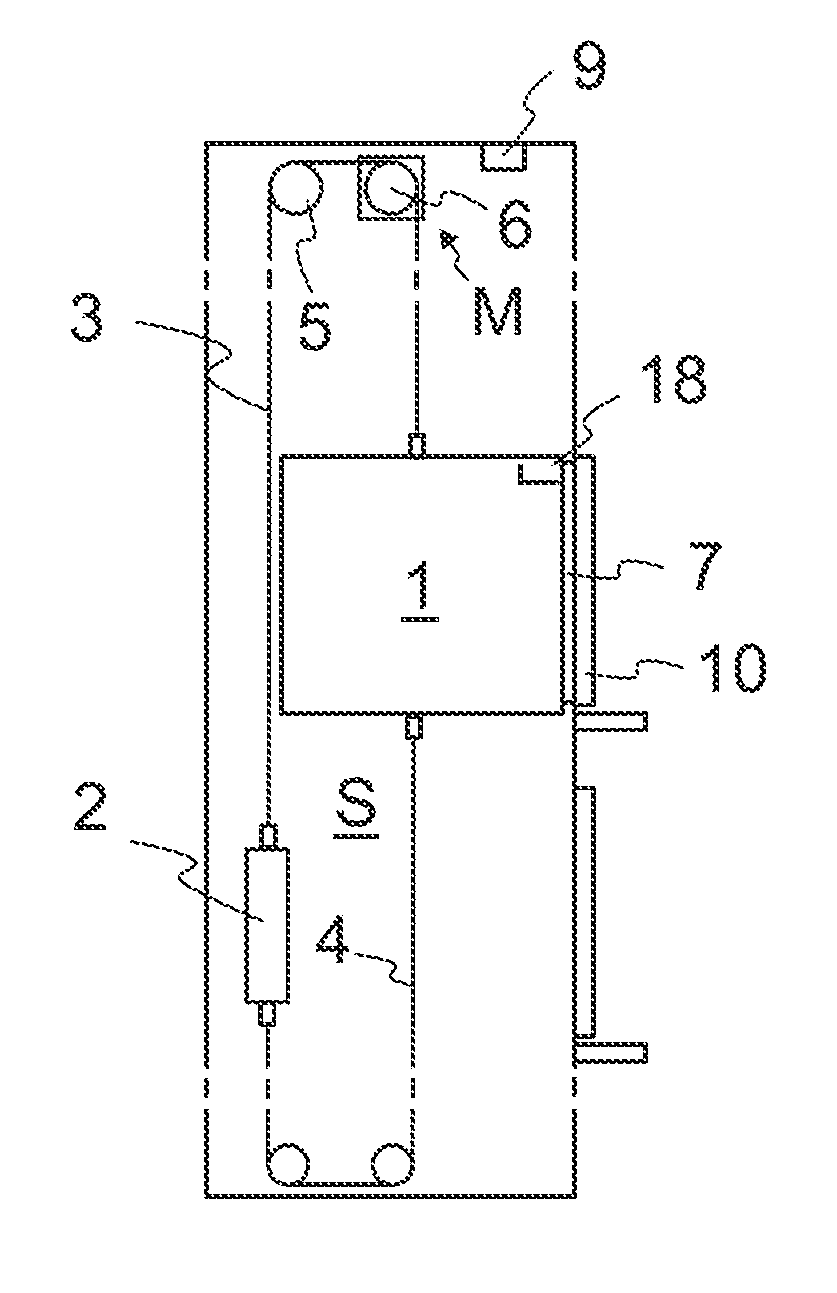

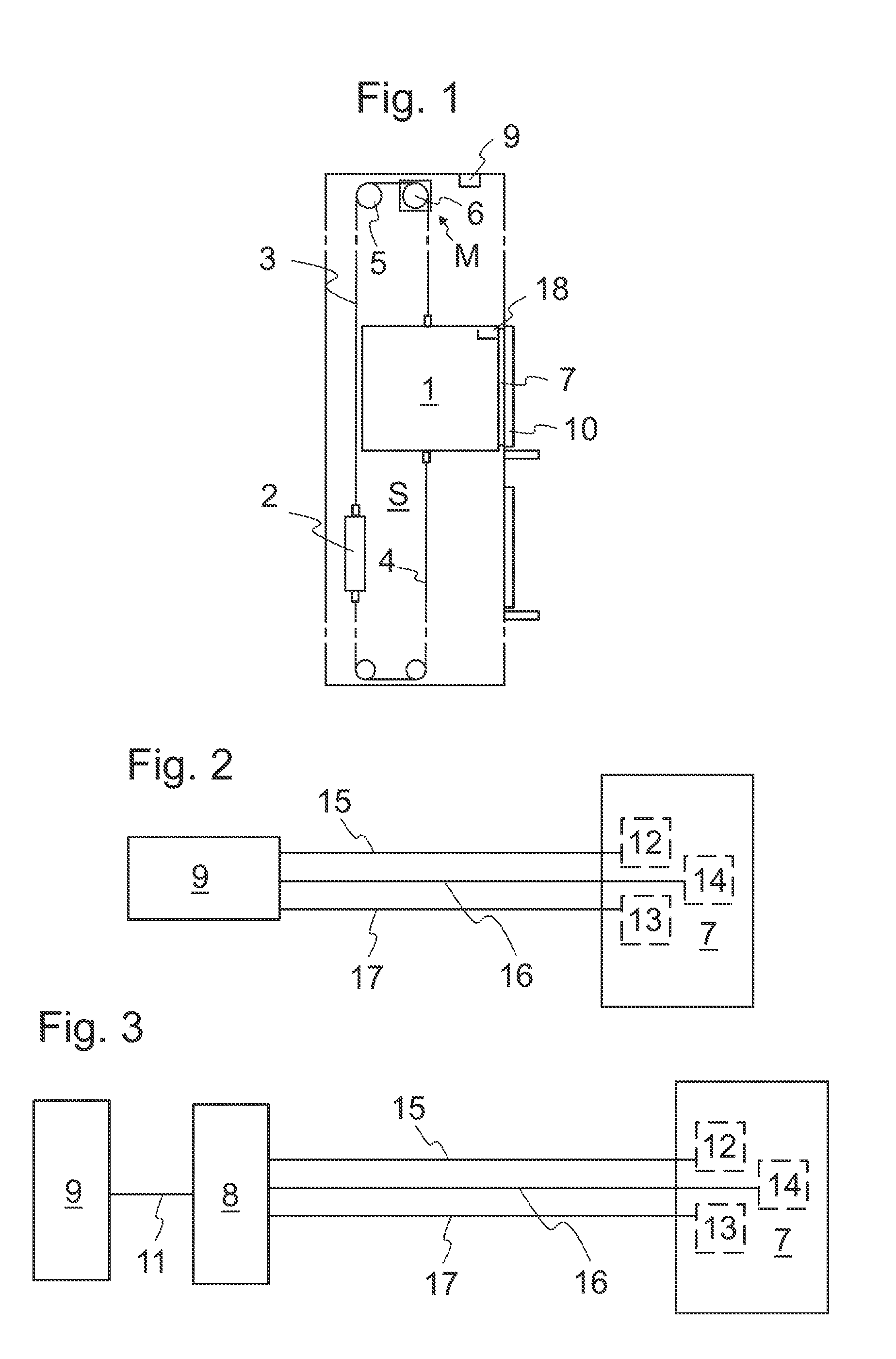

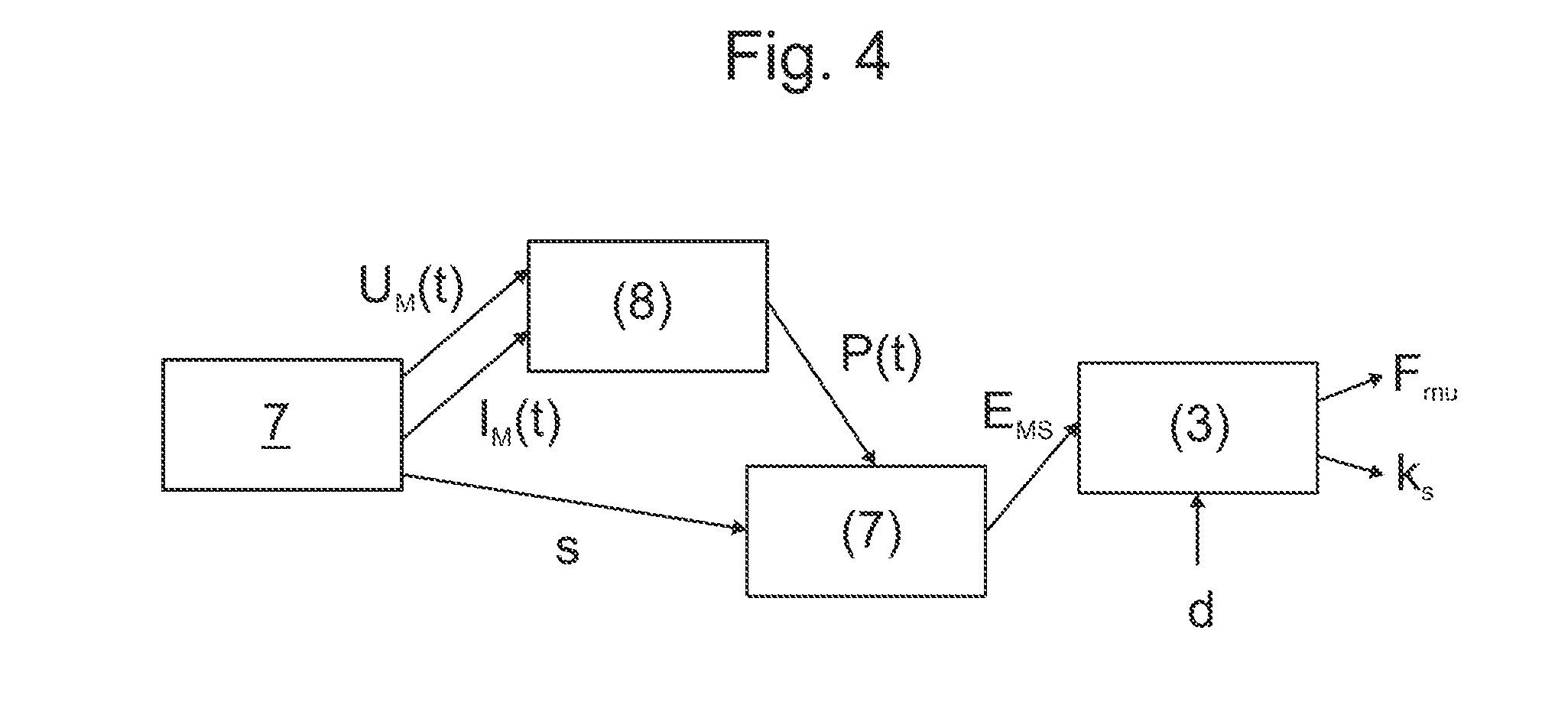

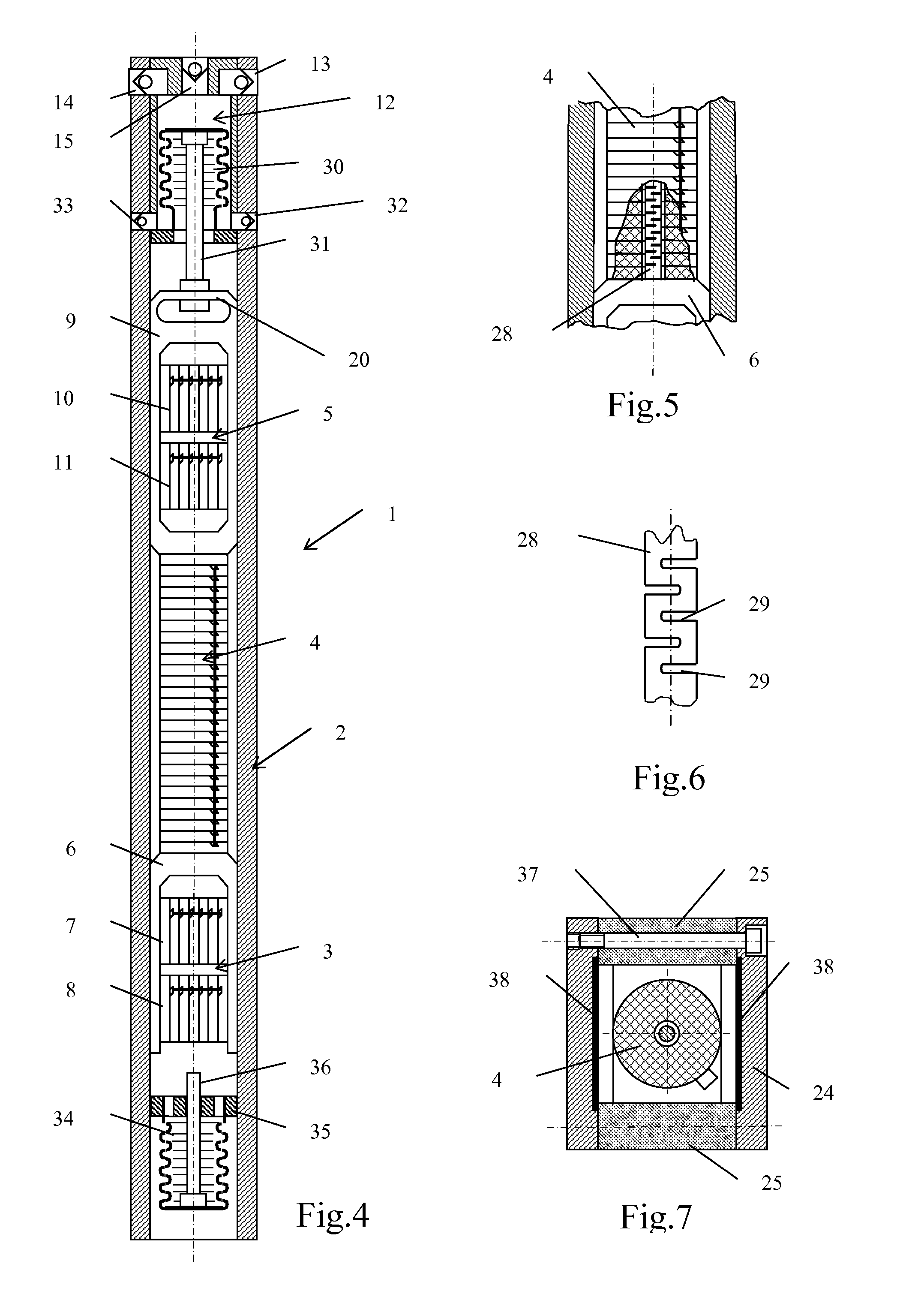

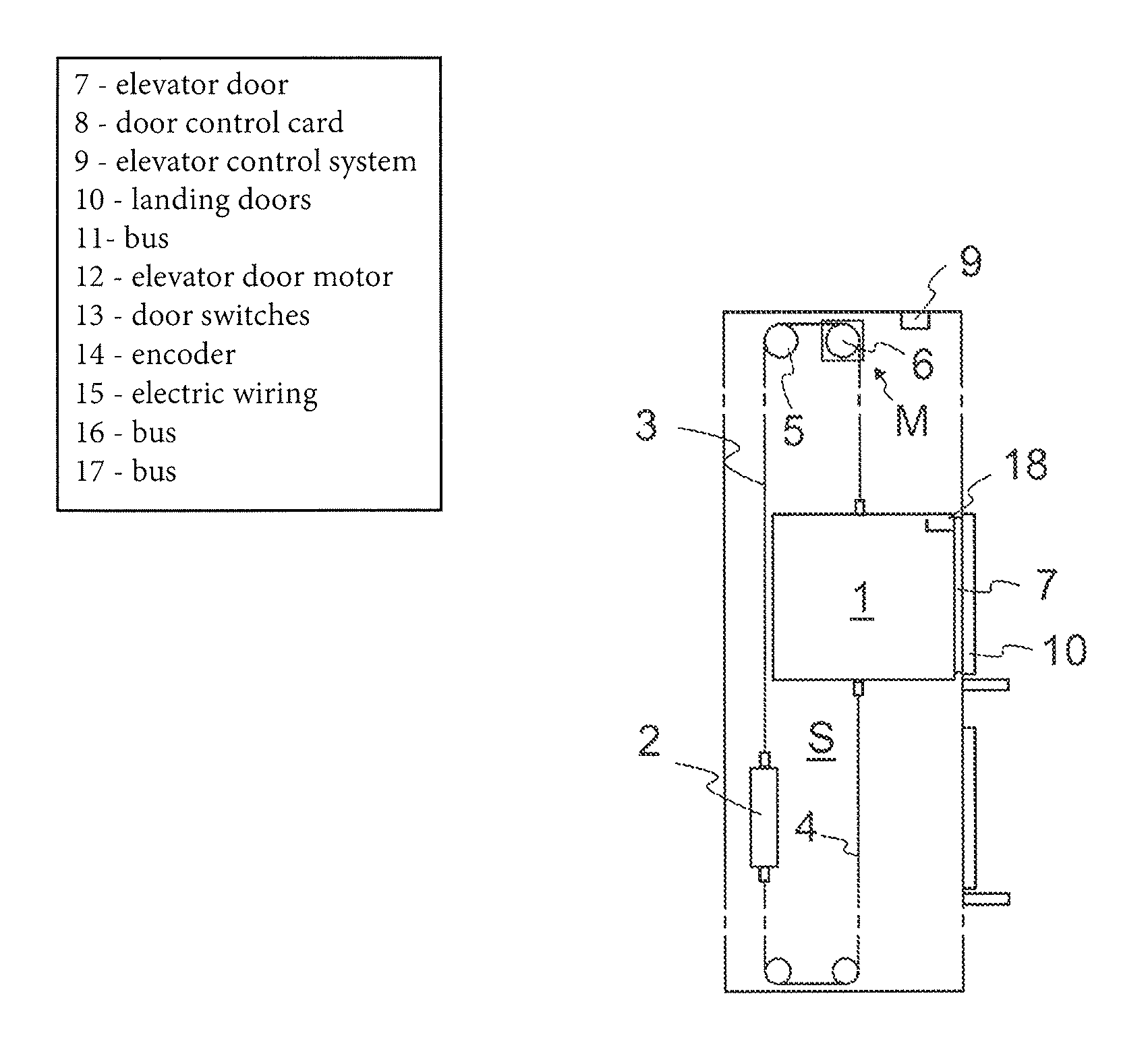

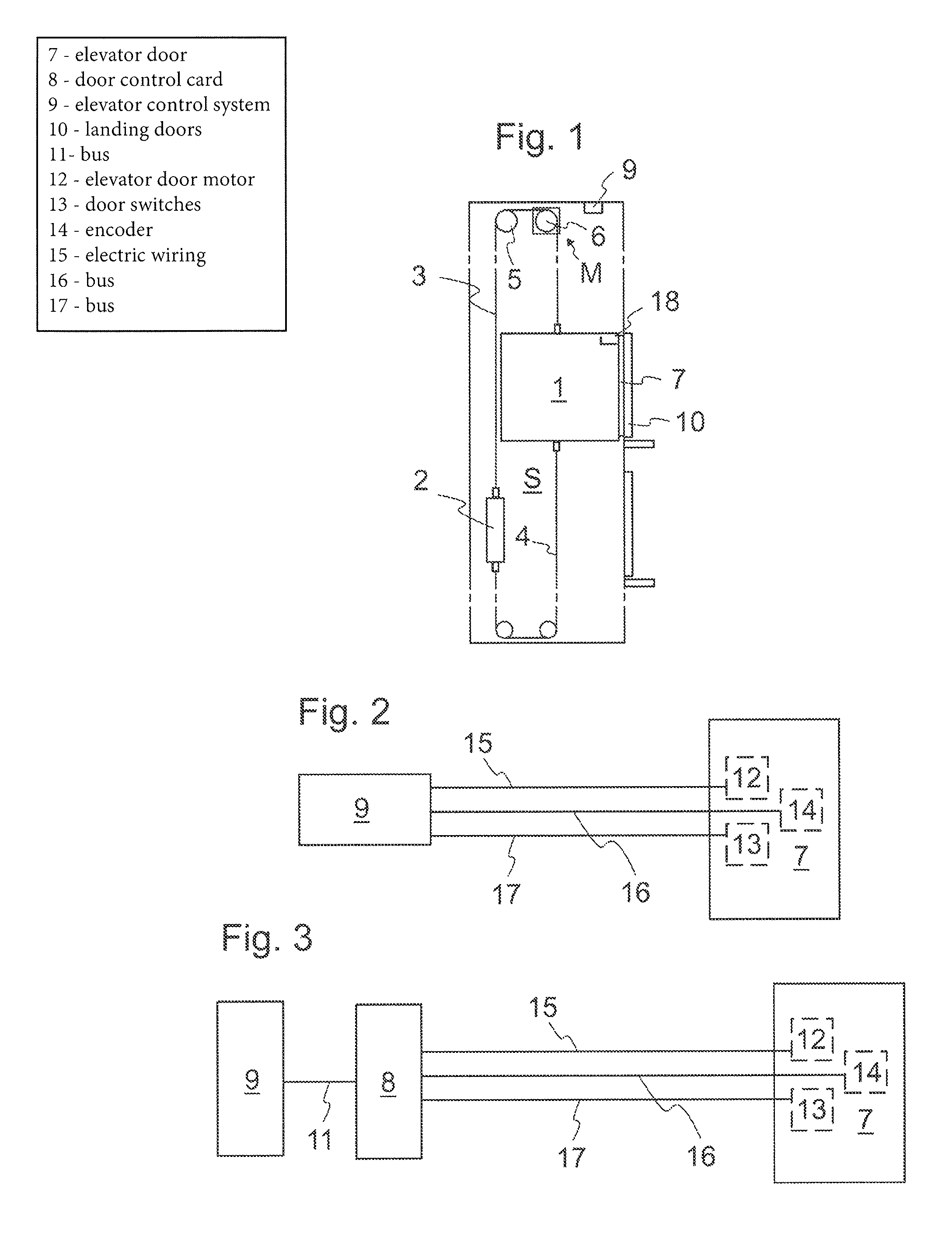

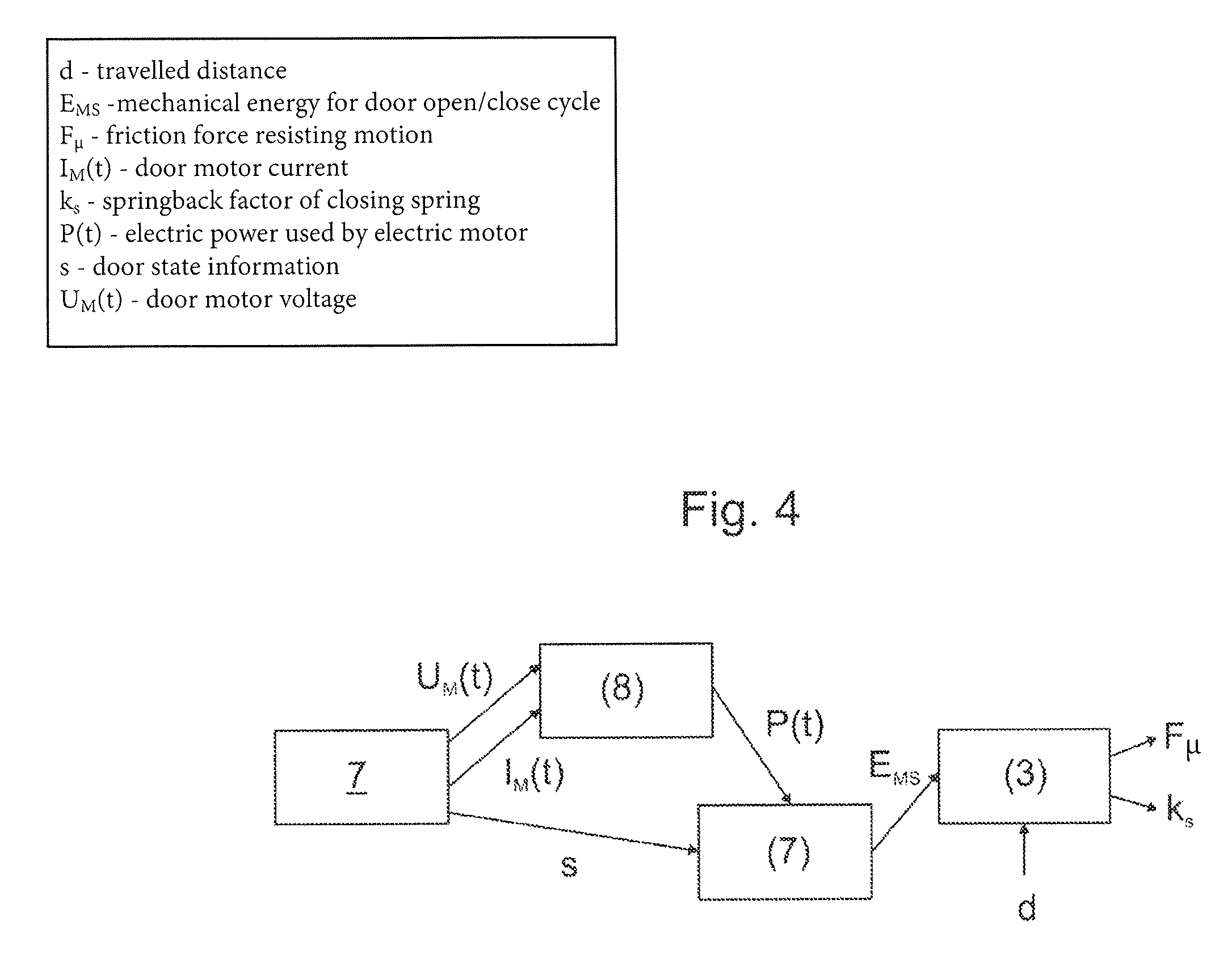

Arrangement and method for monitoring condition of automatic door

ActiveUS20140339024A1Reliable frictionUniform qualityElevatorsBuilding liftsOperating energyControl system

An arrangement and a method for monitoring the operational condition of an automatic door in an elevator, particularly a passenger and / or goods elevator, or in a building, the arrangement includes an automatic door which includes one or more door leaves, which slide horizontally in their location, a door operator, which includes a door motor and a door mechanism for moving the door leaf horizontally in its location, a closing device for closing the automatic door, a control system for the door operator for controlling the door motor, a device configured to define the operational condition of the closing device and the door mechanism of the automatic door, the device configured to define the operational condition of the closing device and the door mechanism of the automatic door includes a mechanism configured to determine the mechanical energy of the shaft in the door motor of the automatic door during an operating cycle.

Owner:KONE CORP

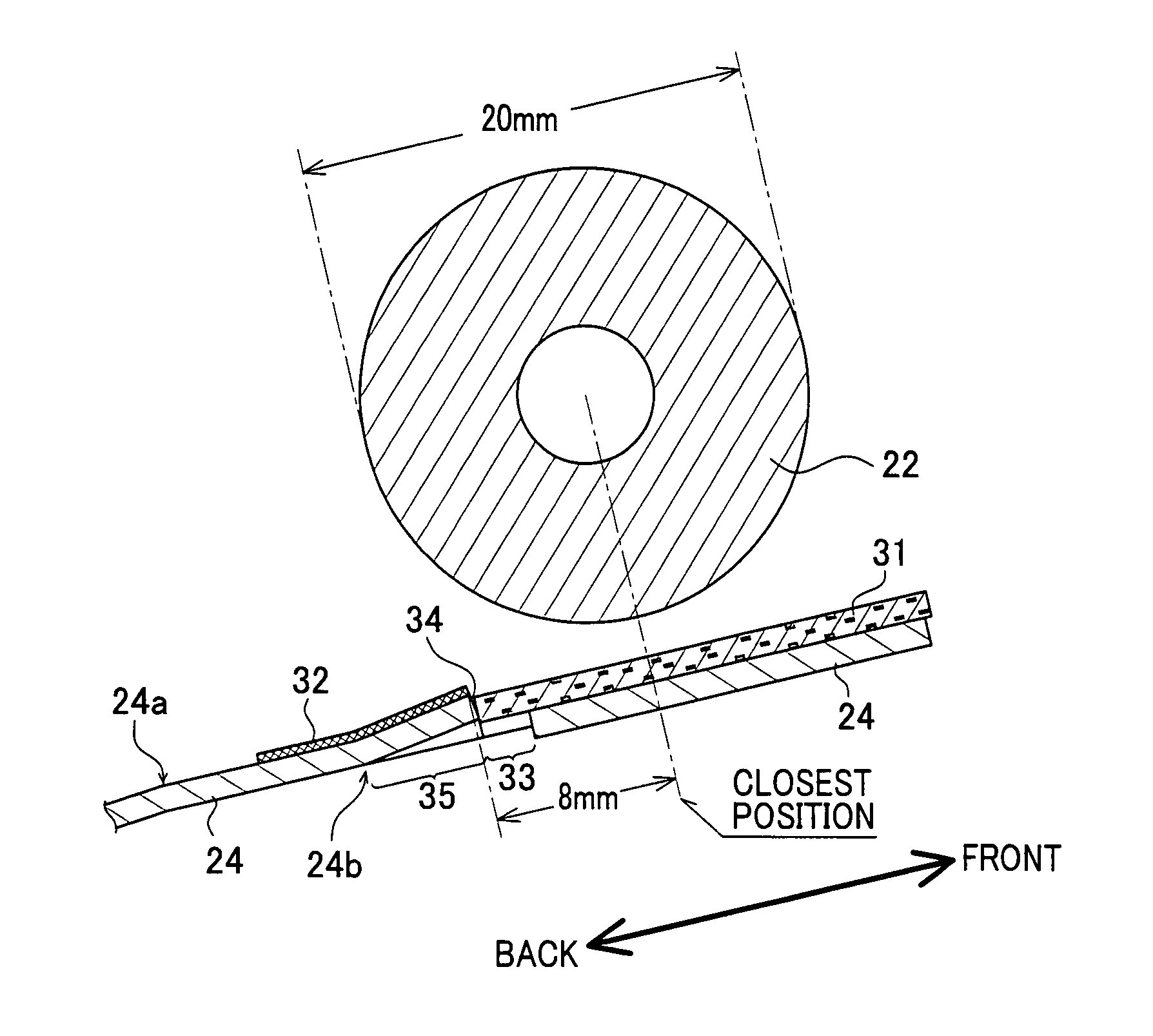

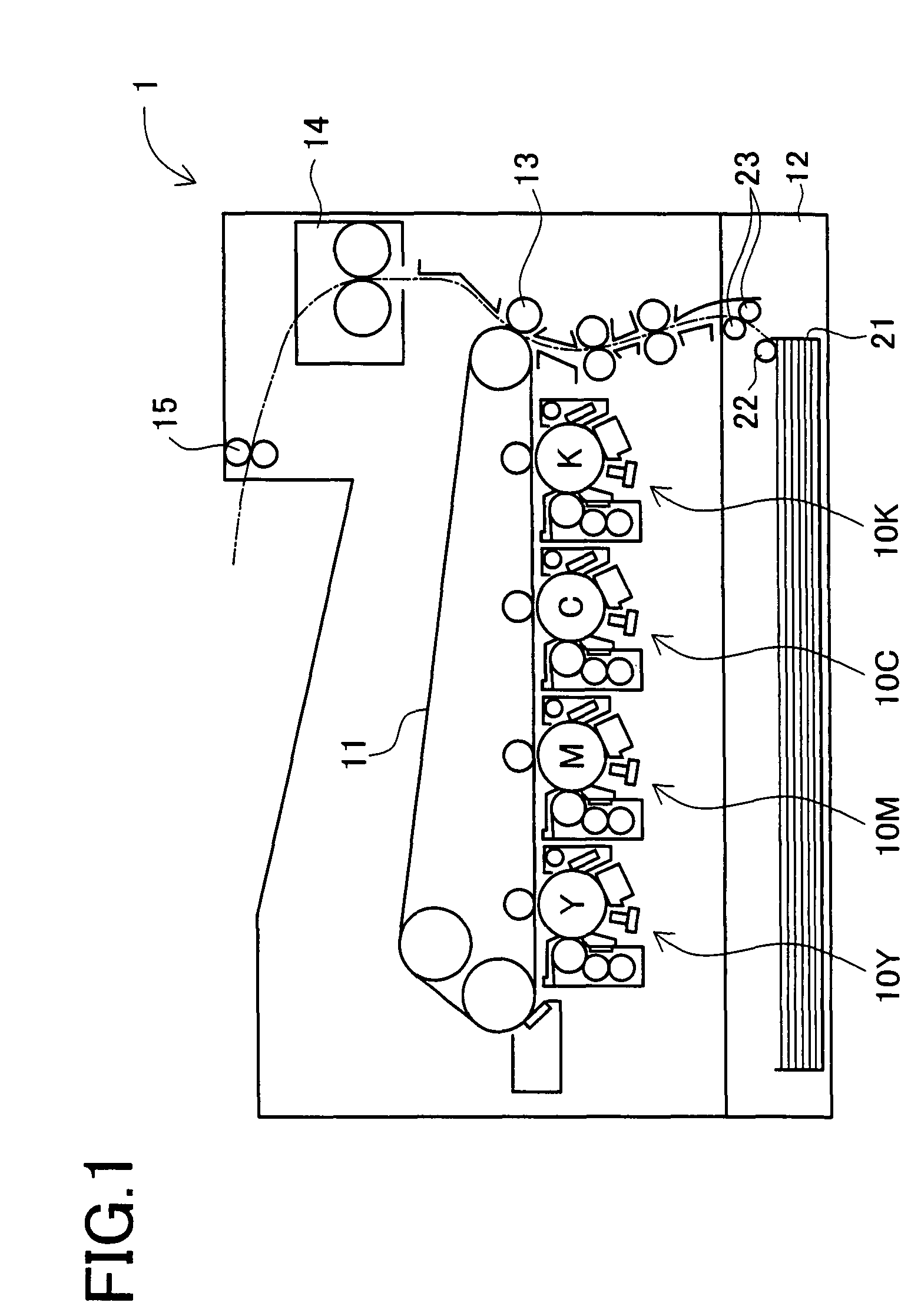

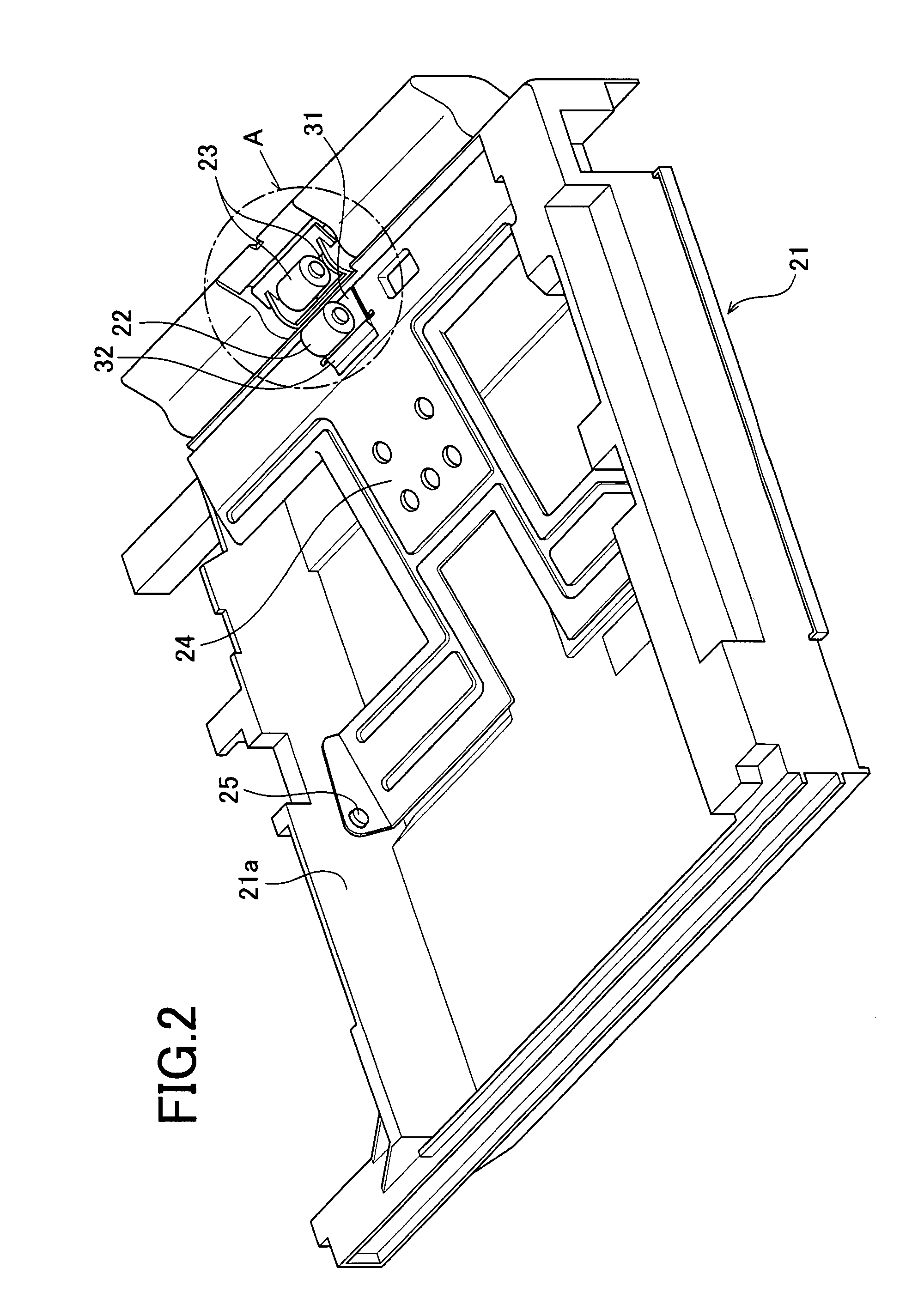

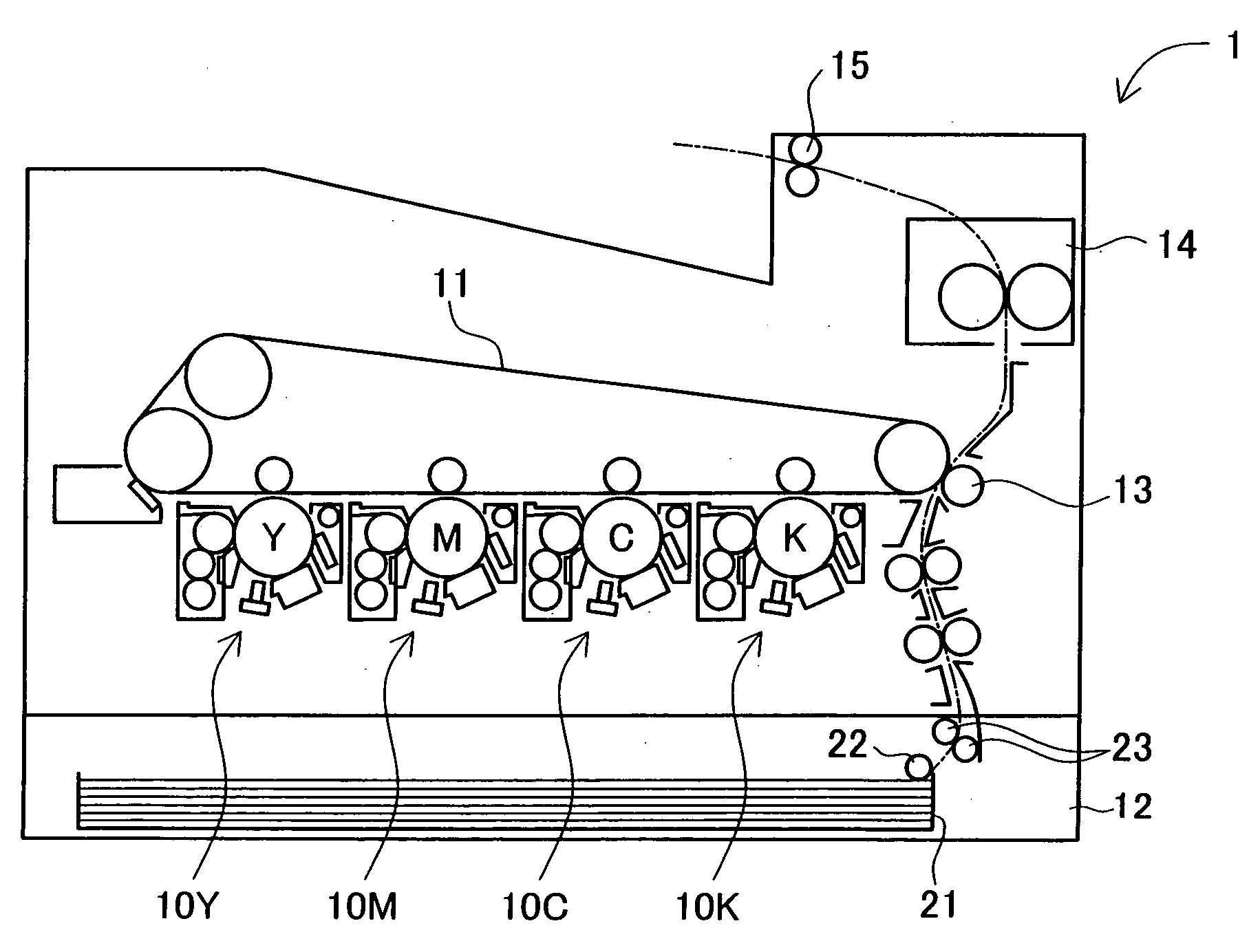

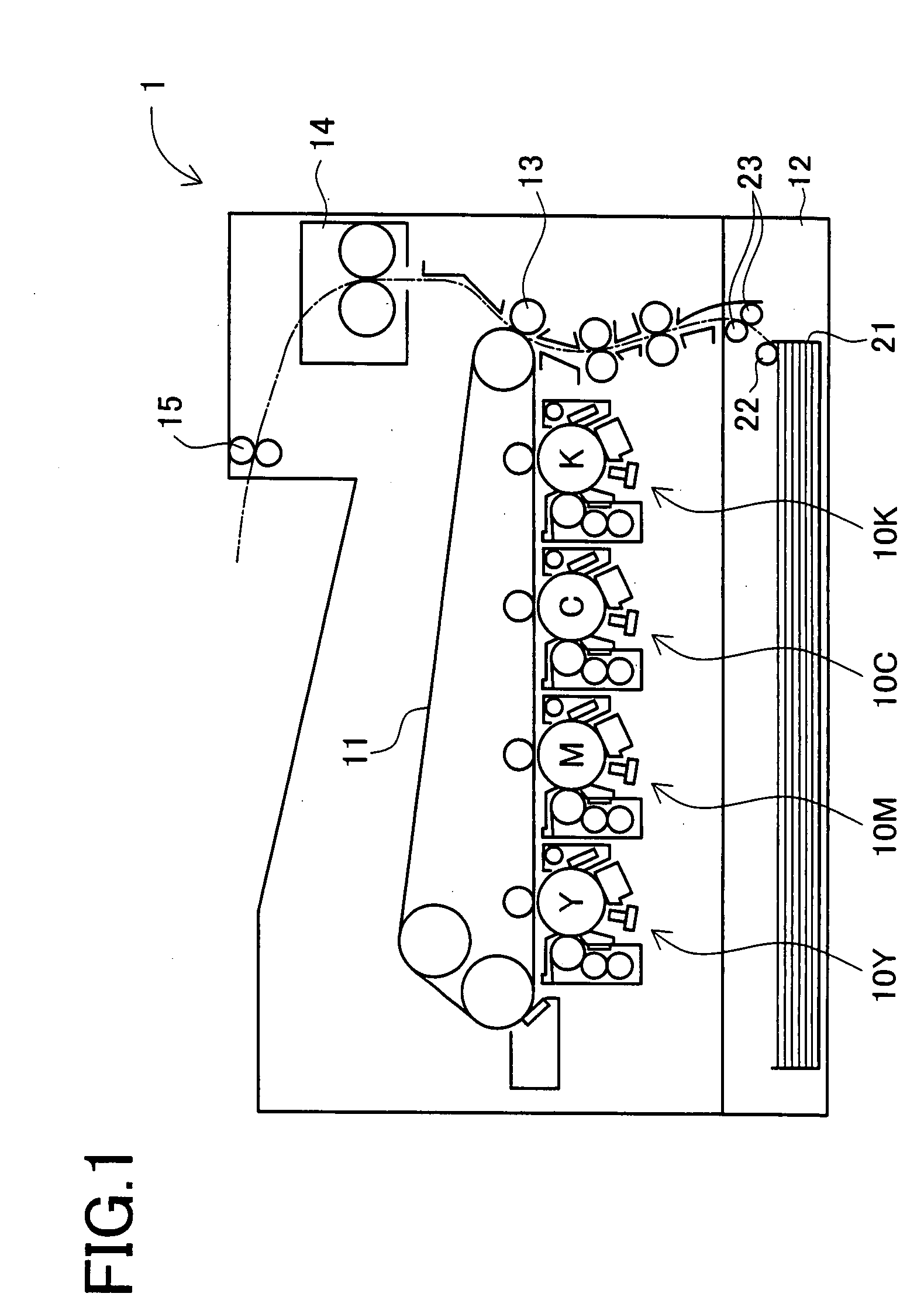

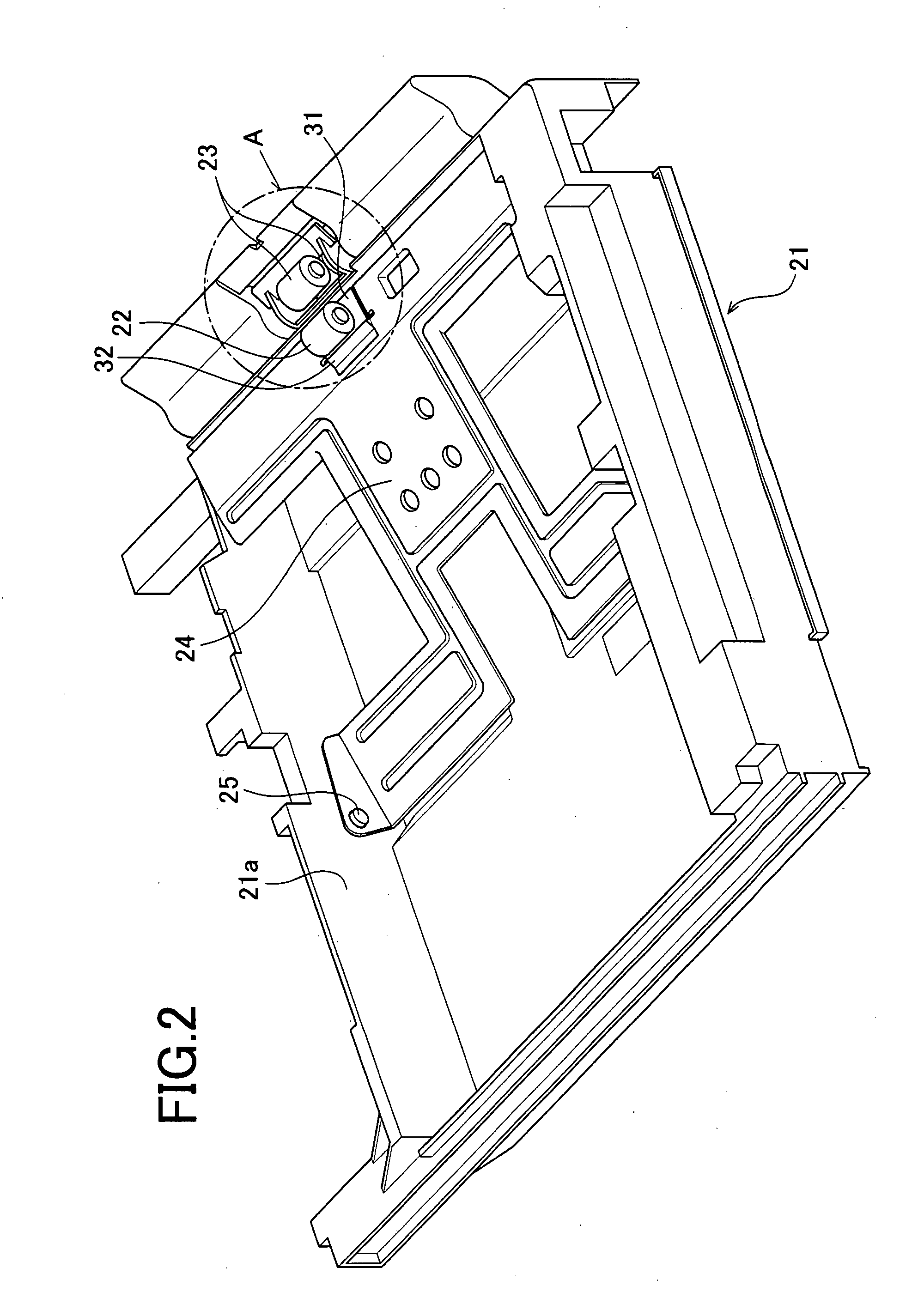

Sheet feeding device, sheet feeding cassette used for the same, and image forming apparatus

ActiveUS7913997B2Less frictional forceDouble-paper feeding is preventedFunction indicatorsArticle separationEngineeringPaper sheet

A sheet feeding device comprises a pick roller; a push-up board; a first friction member located in a position on the push-up board opposed to the pick roller with the sheet bundle interposed therebetween; and a second friction member located in a position on the push-up board upstream in a sheet transferring direction and not opposed to the pick roller. In the sheet feeding device, the second friction member has a most protruding part which protrudes to the sheet bundle more than a sheet bundle side surface of the first friction member, and a dynamic friction coefficient of the second friction member to the sheet is larger than that of the first friction member and smaller than that of the pick roller. Accordingly, double-paper feeding can be prevented and even the last one sheet can be fed regardless types of sheets.

Owner:KONICA MINOLTA BUSINESS TECH INC

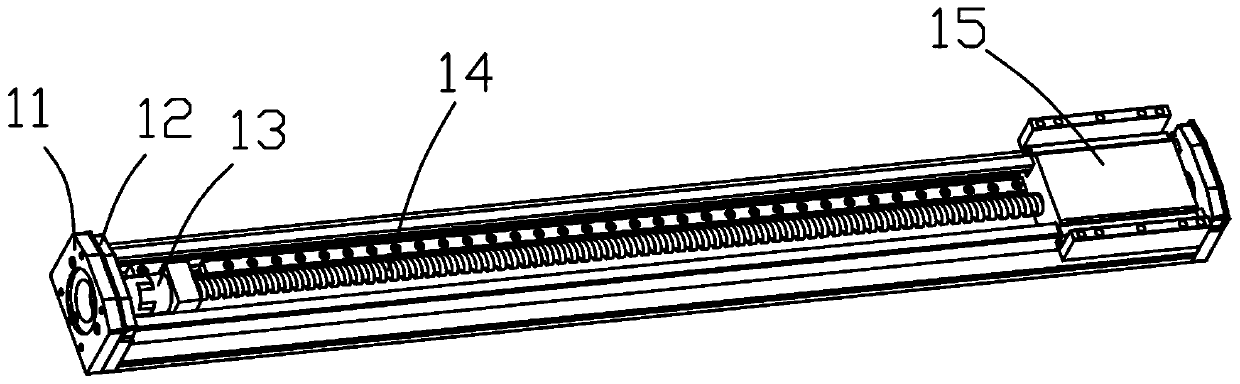

Bolt-hole cap for bolt hole in linear rail

ActiveUS8870508B2Reliable frictionHigh strengthRemovable ornamentalLinear bearingsEngineeringMechanical engineering

Owner:CHIEFTECH PRECISION

Piezoelectric pump

ActiveUS20130287607A1Reliable and versatile and effectiveExtended service lifePumpsPositive-displacement liquid enginesElectricityElectrical impulse

The piezoelectric pump comprises a housing, containing the following components connected in series: a rear piezoelectric clamp section, a piezoelectric extender section and a front piezoelectric clamp section. A displacer of pumped fluid is connected to the front piezoelectric clamp section. Electric pulses accessing at sections from a control station cause said sections to become fixed alternately inside the housing. Under the effect of electric pulses, the piezoelectric extender section moves the displacer step-by-step in one direction. Positive effect achieved by the invention is that of increasing the service life of the piezoelectric pump, expanding the scope of use thereof by increasing the number of fluids that can be pumped and also providing for a greater pressure by preventing contact between the pumped fluid and the friction surfaces of the housing and the piezoelectric clamp sections.

Owner:RENK LIMITED LIABILITY

Monitoring operating condition of automatic elevator door

ActiveUS9586790B2Reliable frictionUniform qualityElevatorsBuilding liftsOperating energyControl system

An arrangement and a method for monitoring the operational condition of an automatic door in an elevator, particularly a passenger and / or goods elevator, or in a building, the arrangement includes an automatic door which includes one or more door leaves, which slide horizontally in their location, a door operator, which includes a door motor and a door mechanism for moving the door leaf horizontally in its location, a closing device for closing the automatic door, a control system for the door operator for controlling the door motor, a device configured to define the operational condition of the closing device and the door mechanism of the automatic door, the device configured to define the operational condition of the closing device and the door mechanism of the automatic door includes a mechanism configured to determine the mechanical energy of the shaft in the door motor of the automatic door during an operating cycle.

Owner:KONE CORP

Sheet feeding device, sheet feeding cassette used for the same, and image forming apparatus

ActiveUS20080191407A1Less frictional forceDouble-paper feeding is preventedFunction indicatorsArticle separationPaper sheetSheet material

A sheet feeding device comprises a pick roller; a push-up board; a first friction member located in a position on the push-up board opposed to the pick roller with the sheet bundle interposed therebetween; and a second friction member located in a position on the push-up board upstream in a sheet transferring direction and not opposed to the pick roller. In the sheet feeding device, the second friction member has a most protruding part which protrudes to the sheet bundle more than a sheet bundle side surface of the first friction member, and a dynamic friction coefficient of the second friction member to the sheet is larger than that of the first friction member and smaller than that of the pick roller. Accordingly, double-paper feeding can be prevented and even the last one sheet can be fed regardless types of sheets.

Owner:KONICA MINOLTA BUSINESS TECH INC

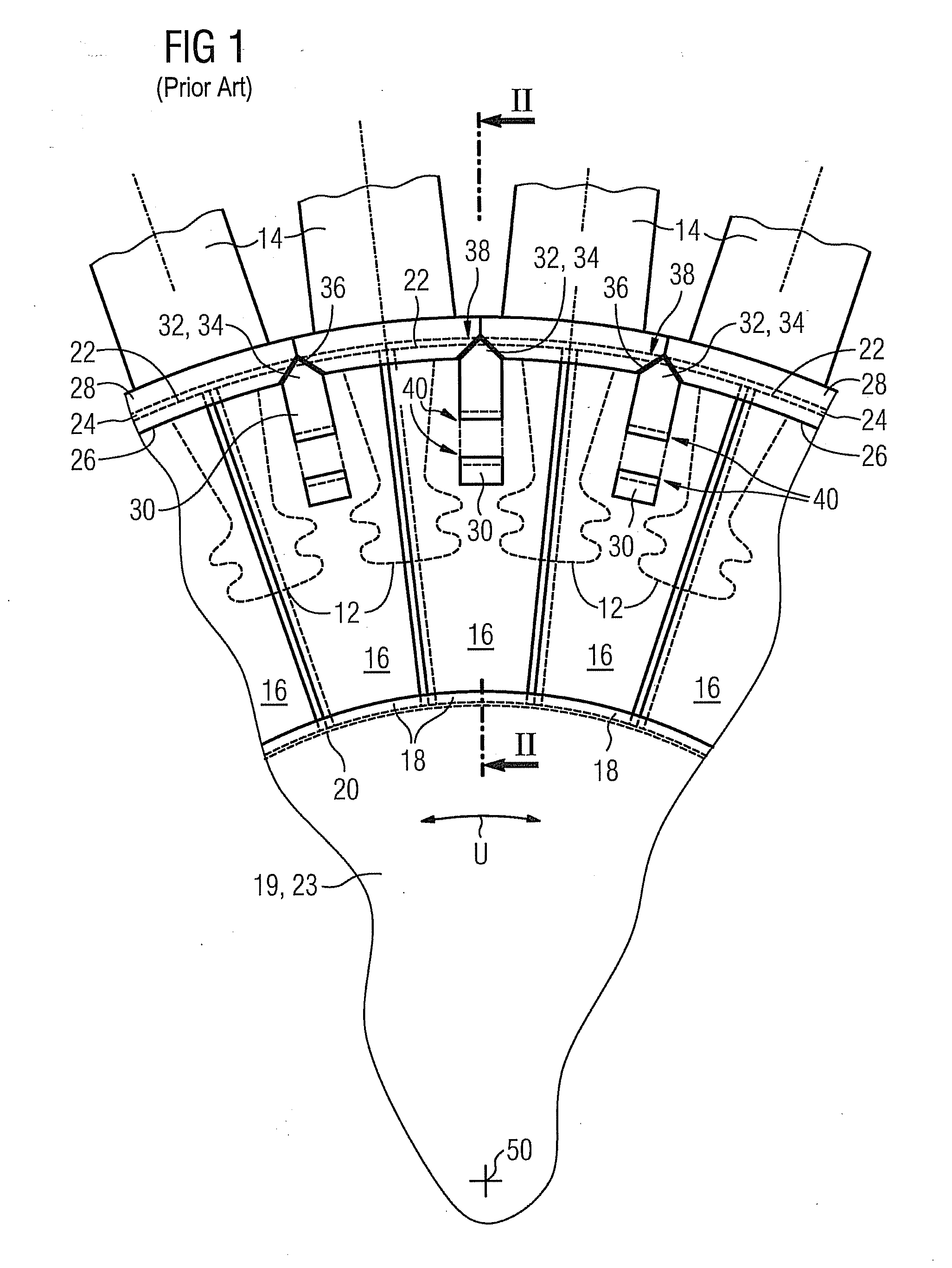

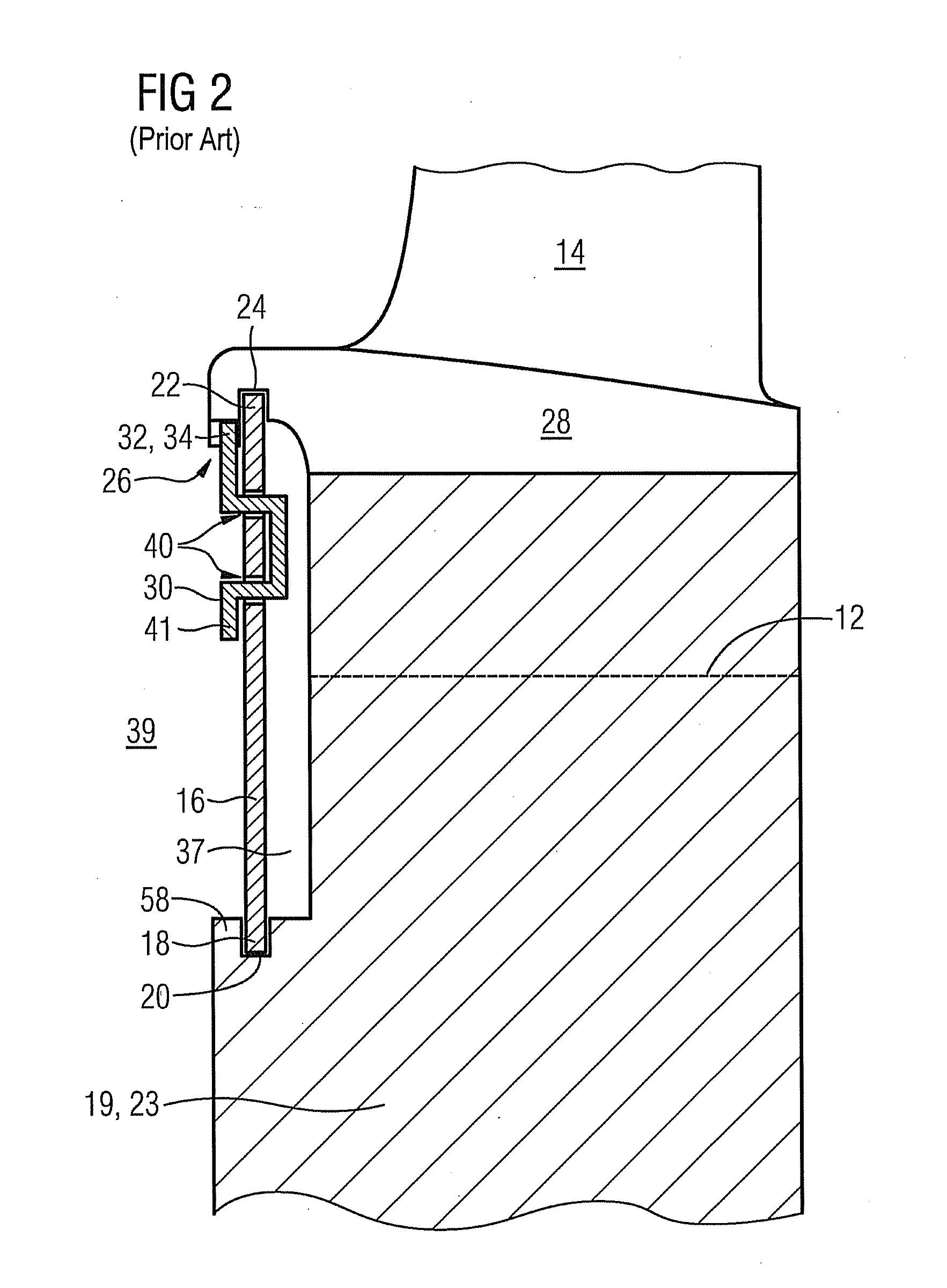

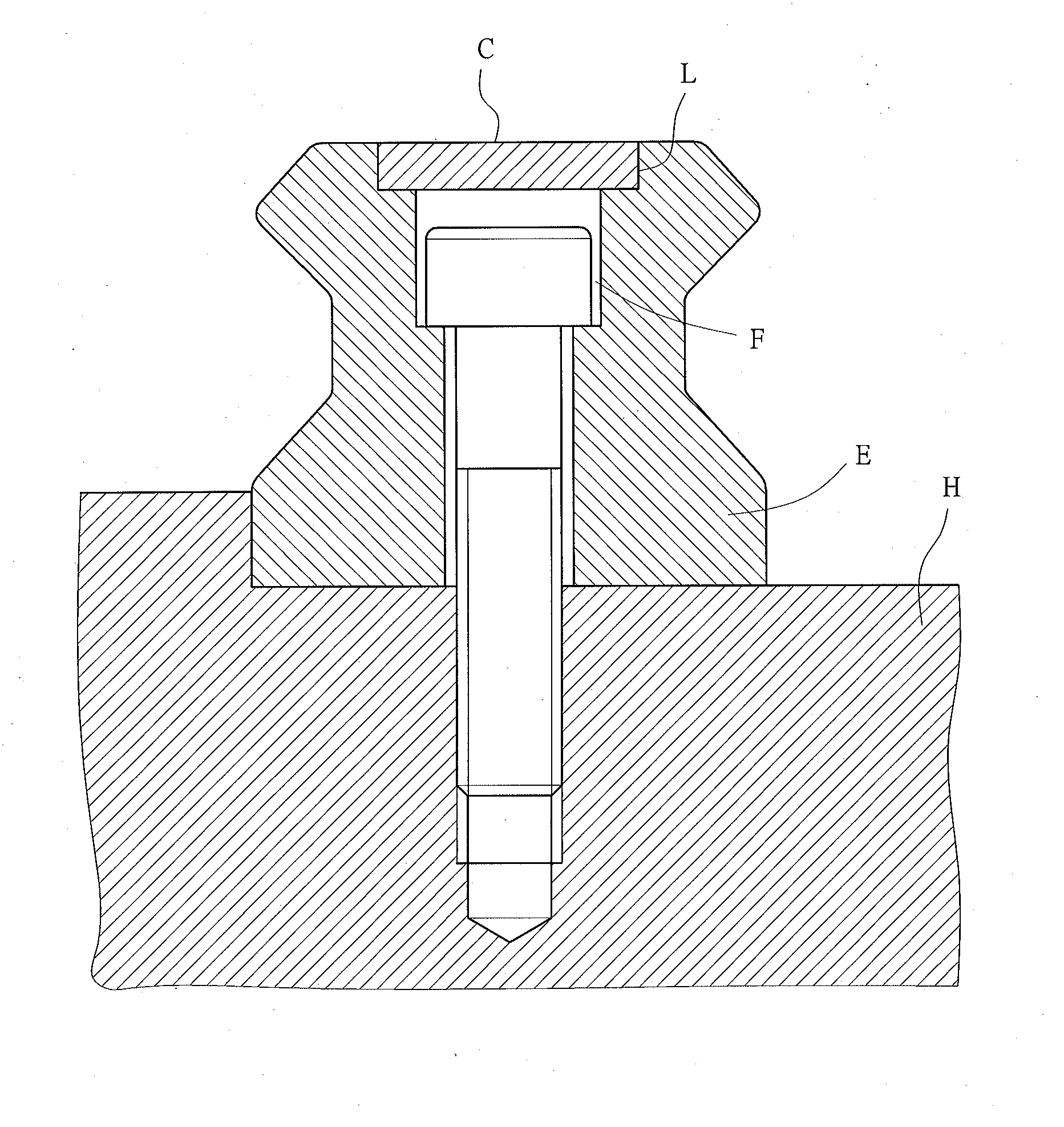

Arrangement for axially securing rotating blades in arotor, and gas turbine having such an arrangement

InactiveUS20110027092A1Improve installationGood removal effectPropellersRotary propellersGas turbinesEngineering

An arrangement for axial locking of rotating blades in a rotor is provided. The arrangement includes a shaft collar, a projection, plate-like sealing elements, and a blocking element. The sealing elements are provided for axially securing the rotating blades. At least one sealing element has an opening for securing the sealing elements against displacement in the circumferential direction. The blocking element is inserted in a recess from the end side of the shaft collar and blocks the displacement path of the sealing element. In order for the blocking element to be secured against unintentional releasing, the blocking element is fastened on the rotor disk using plastic deformation.

Owner:SIEMENS AG

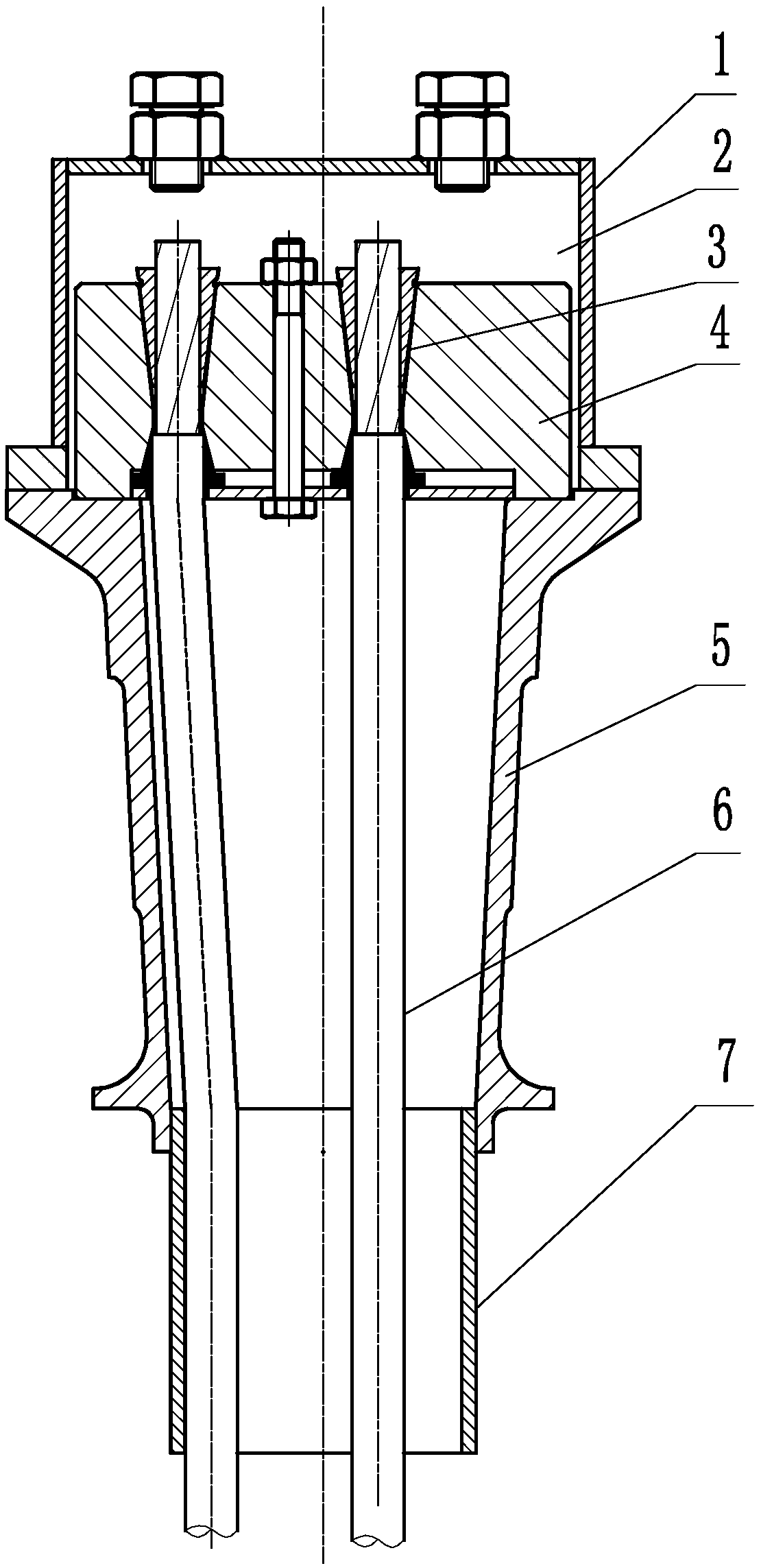

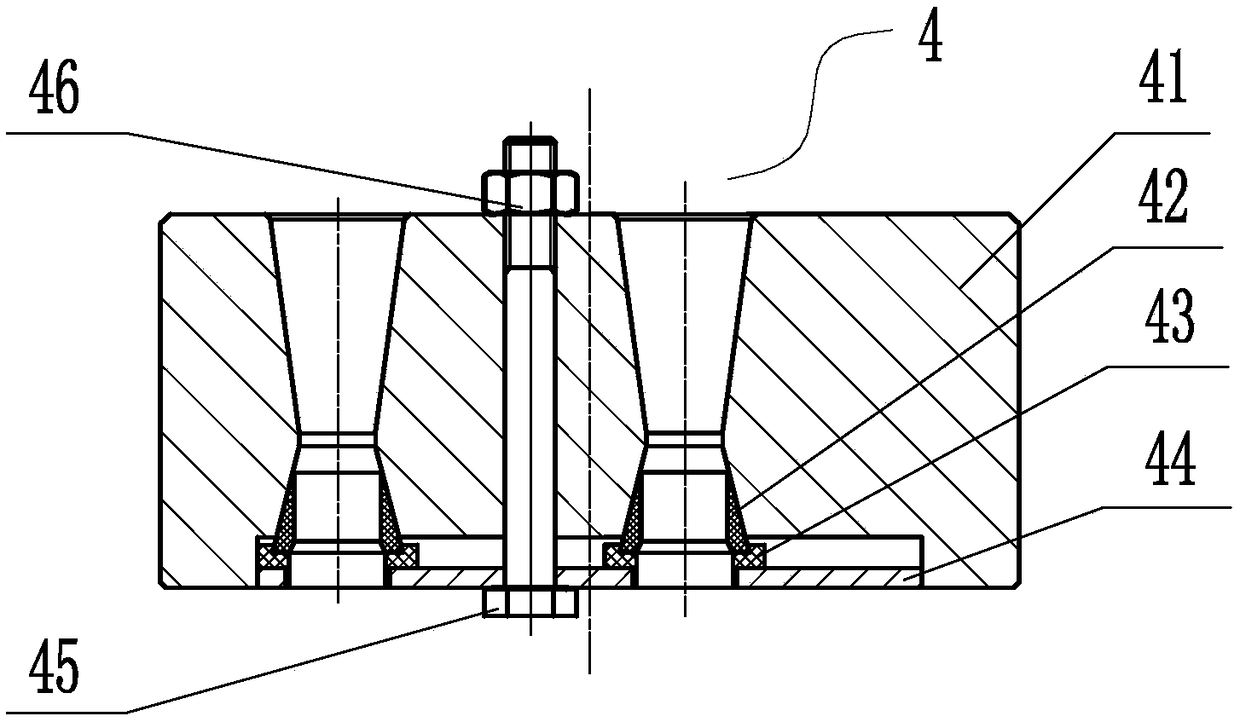

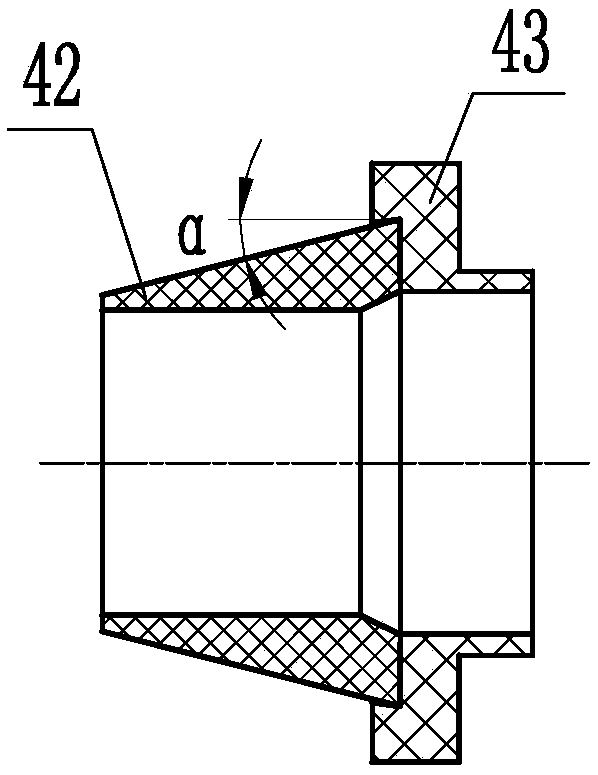

Inside single-beam sealed prestressed group-anchor system and construction method thereof

ActiveCN108643454ANot prone to corrosion failureImprove sealingBuilding reinforcementsBuilding material handlingRubber ringPre stress

The invention discloses an inside single-beam sealed prestressed group-anchor system which comprises a protection cover assembly, working clamping pieces, a sealing anchor plate assembly, anchor bearing plates, a plurality of single-beam sealed prestressed ribs and pre-embedded channels; the sealing anchor plate assembly comprises working anchor plates, rubber cone sleeves, plastic limiting sleeves and a pressing plate; the rubber cone sleeves are of a multiple-piece wedge-shaped rubber ring structure; and the plastic limiting sleeves are arranged to be hollow round shaft sleeves with unequaldiameters and steps. In an installation state, the prestressed ribs correspondingly penetrate through the pressing plate, the plastic limiting sleeves, the rubber cone sleeves located in cone holes IIand cone holes I of the working anchor plates; the working clips clamps the prestressed ribs; the rubber cone sleeves tightly press and cooperate with the working anchor plates cone holes II, and therubber cone sleeves tightly press and cooperate with the prestressed ribs PE protection sleeves. The group-anchor system is mainly used for working conditions with longitudinal replaceable prestressed ribs inside. The sealing anchor plate assembly is used for effectively sealing and connecting with the exposed parts of the prestressed ribs PE protection sleeves, and therefore effectively sealingand anti-corrosion protection are achieved for the prestressed ribs; and construction is simple and practicability is high.

Owner:LIUZHOU OVM MASCH CO LTD

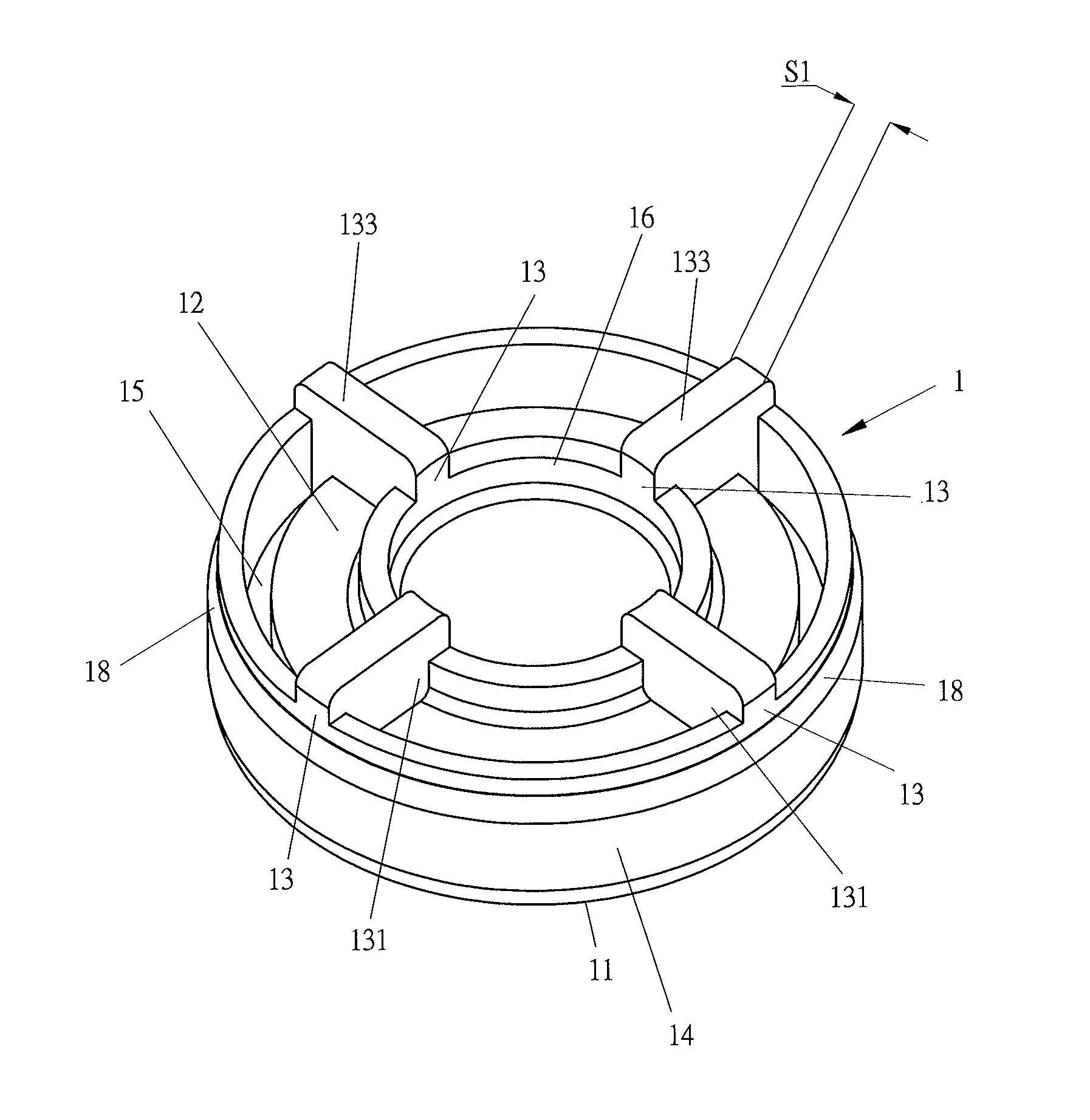

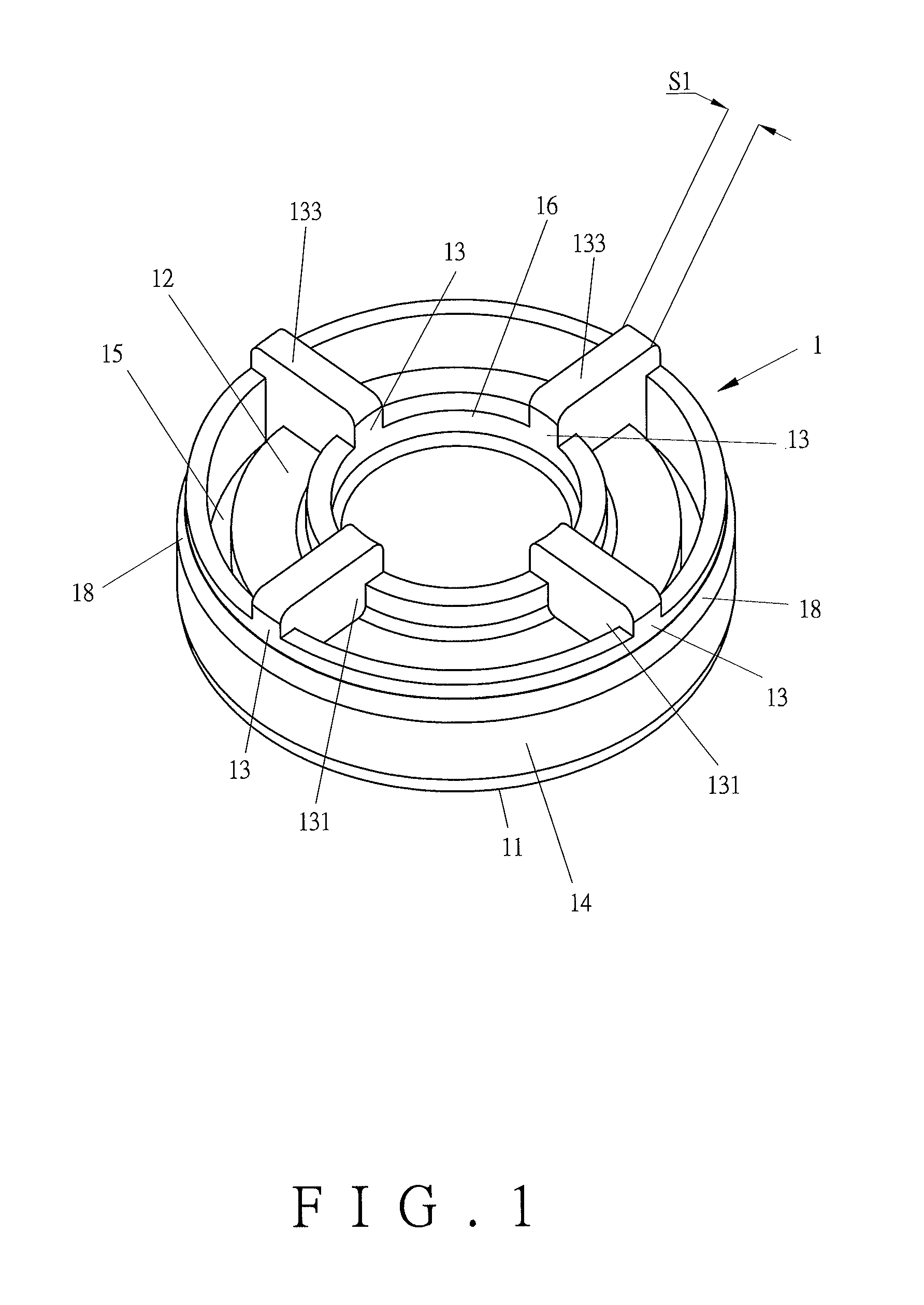

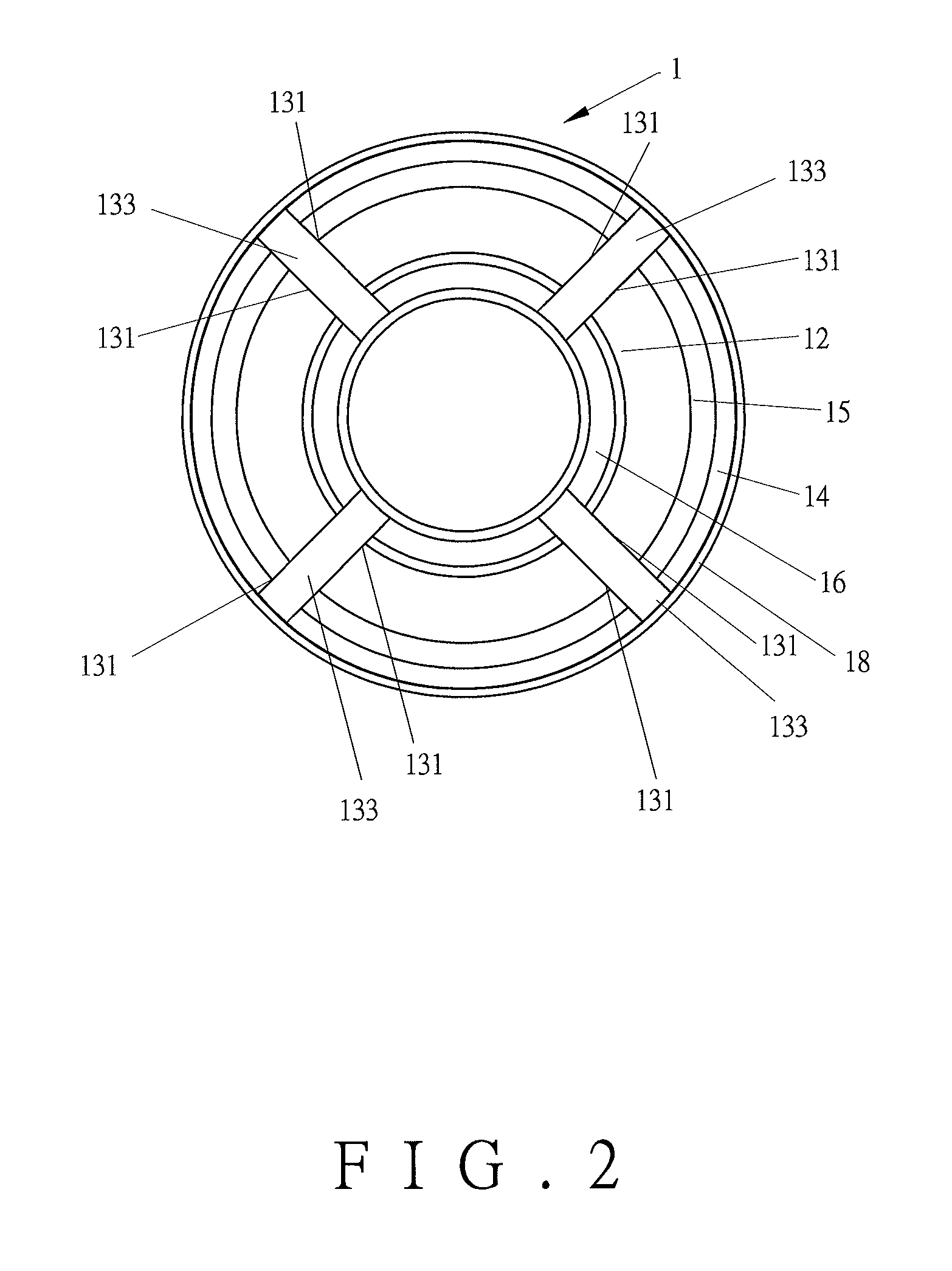

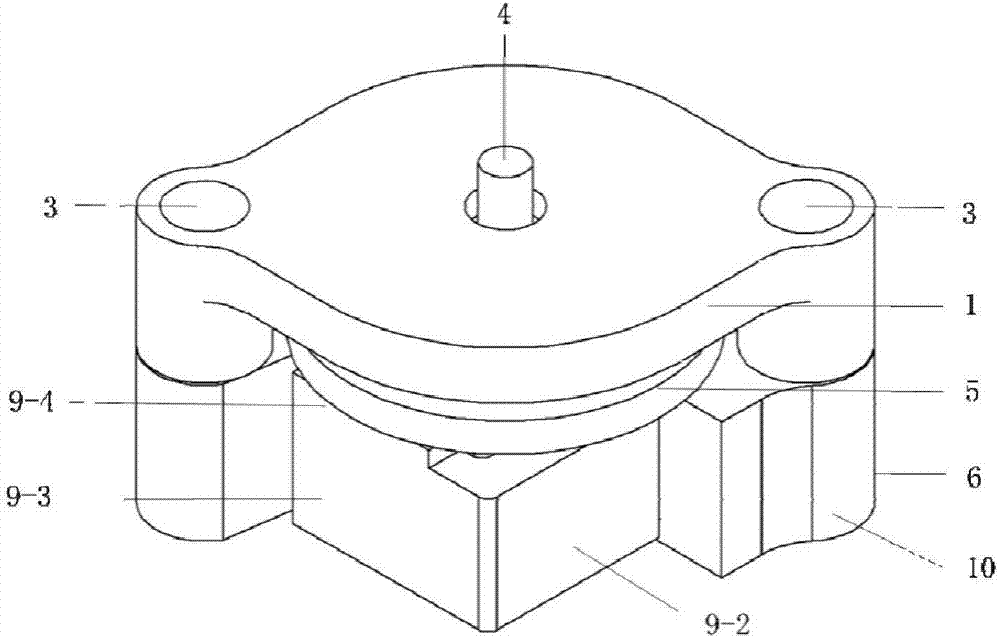

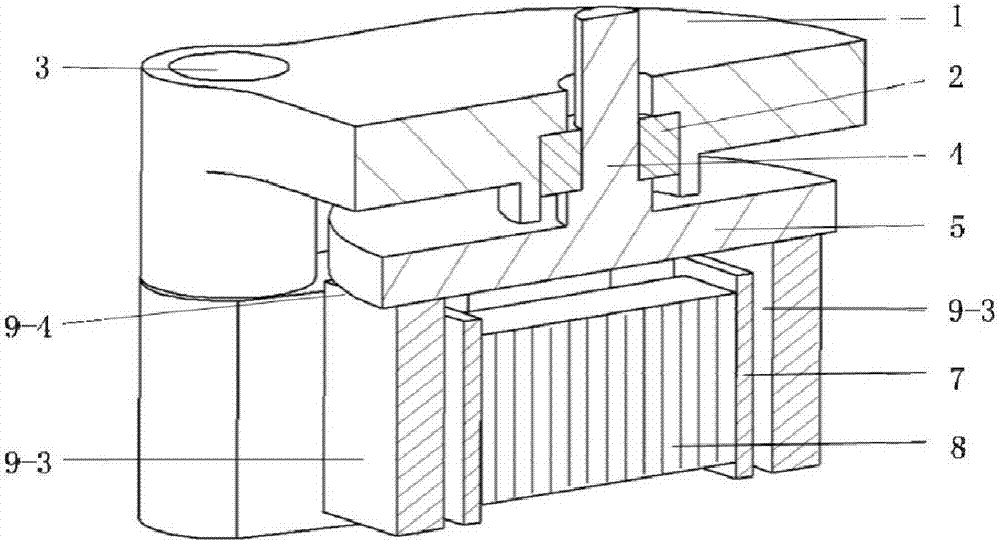

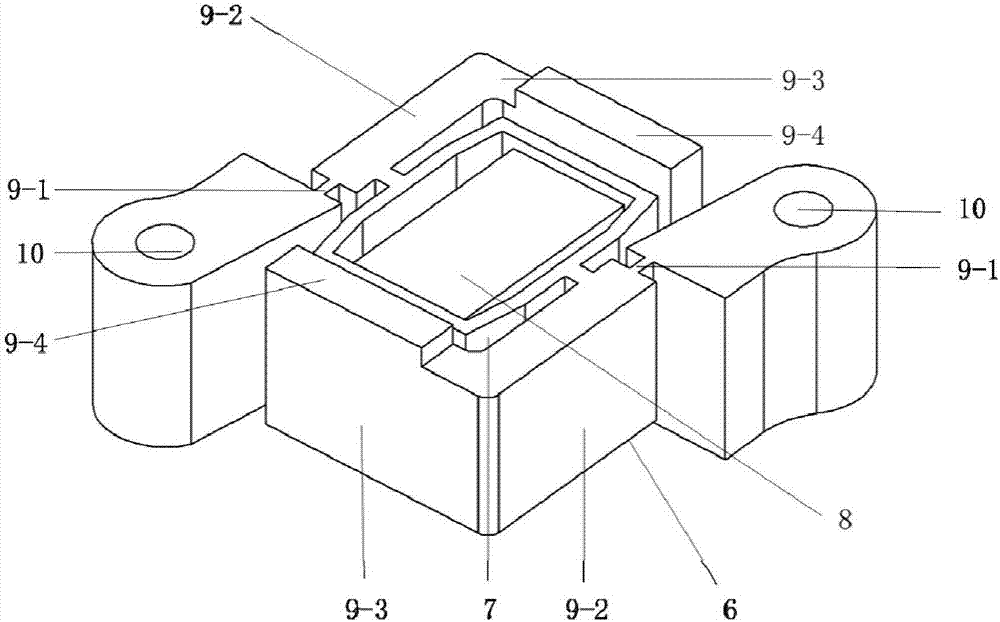

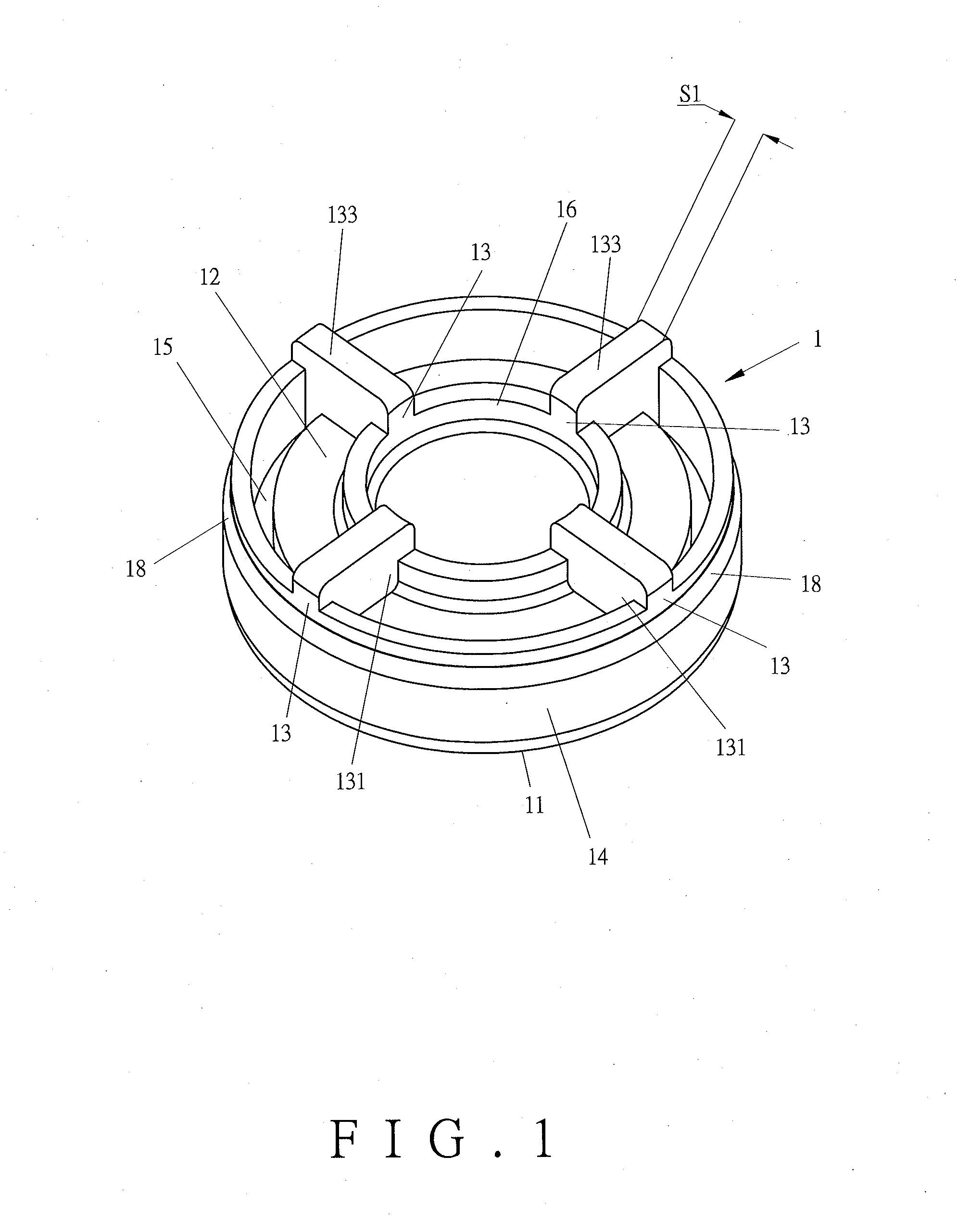

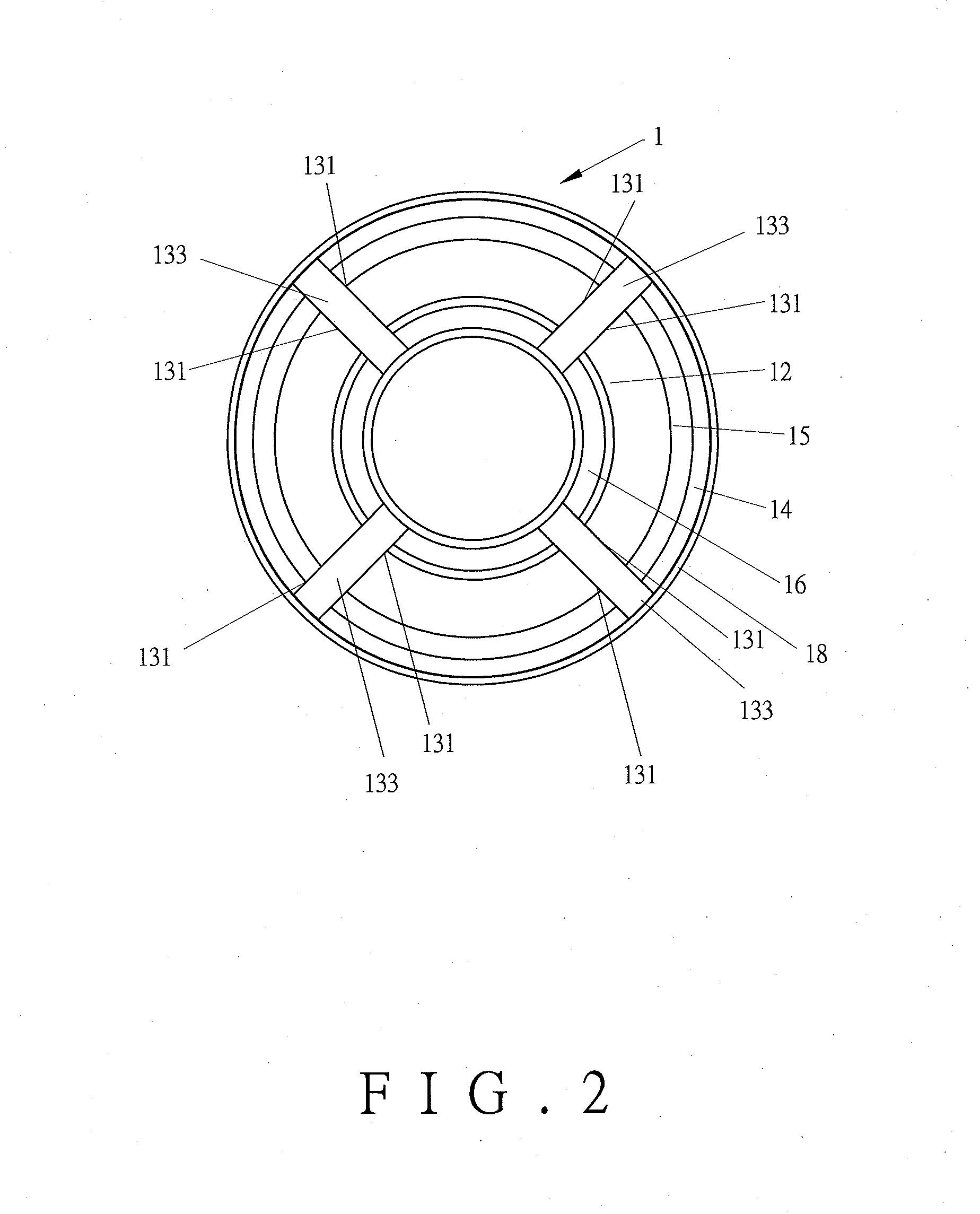

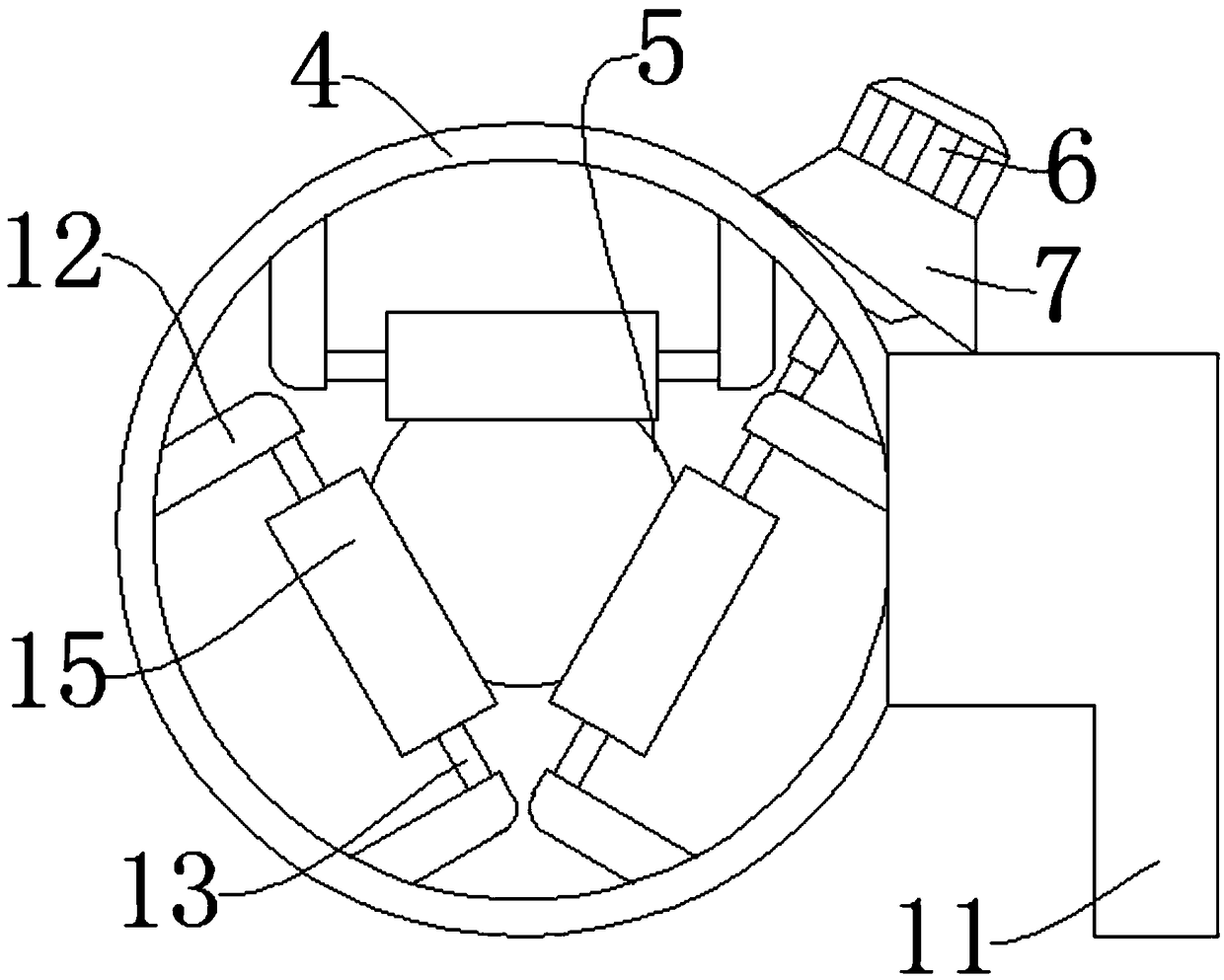

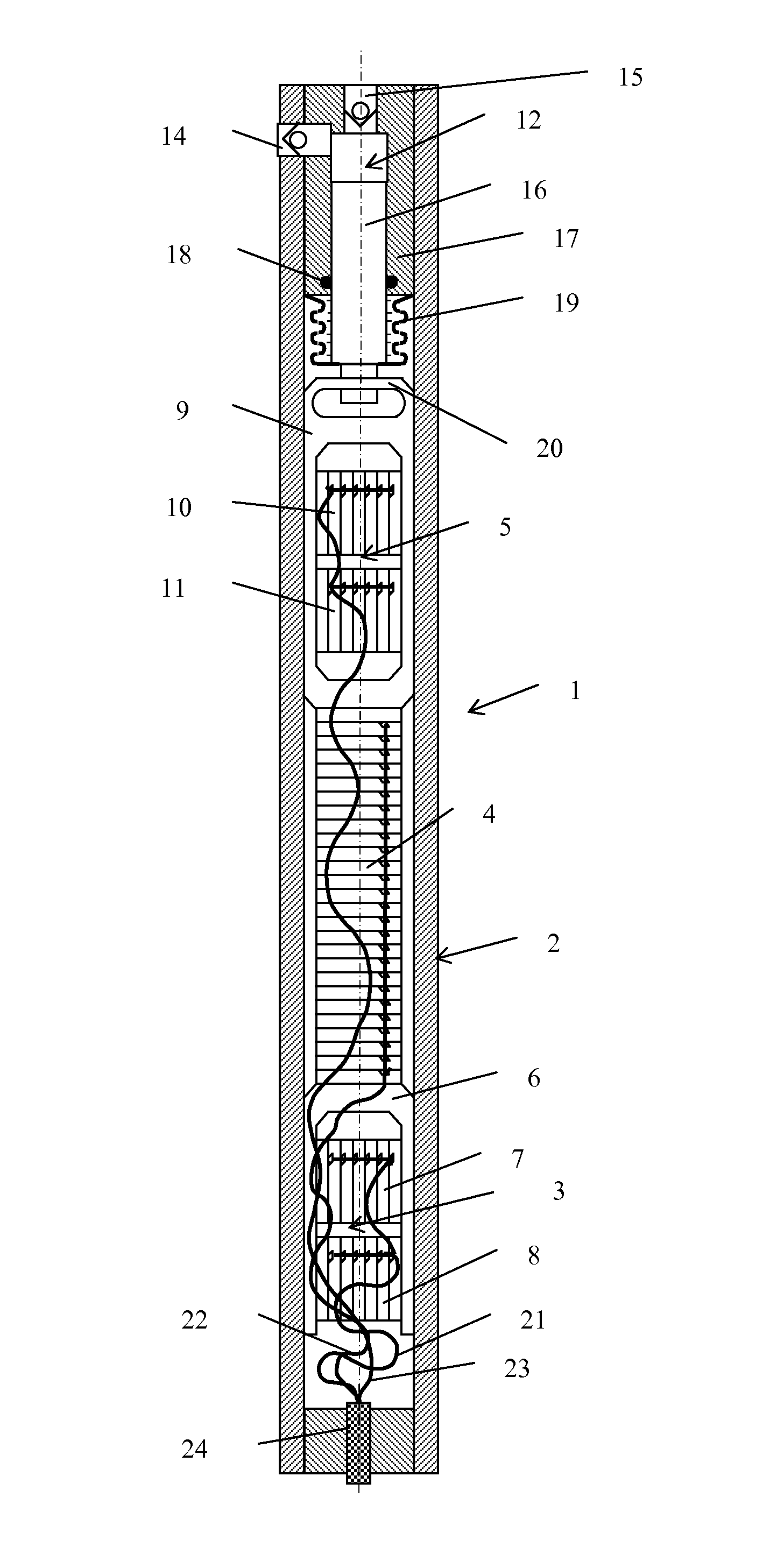

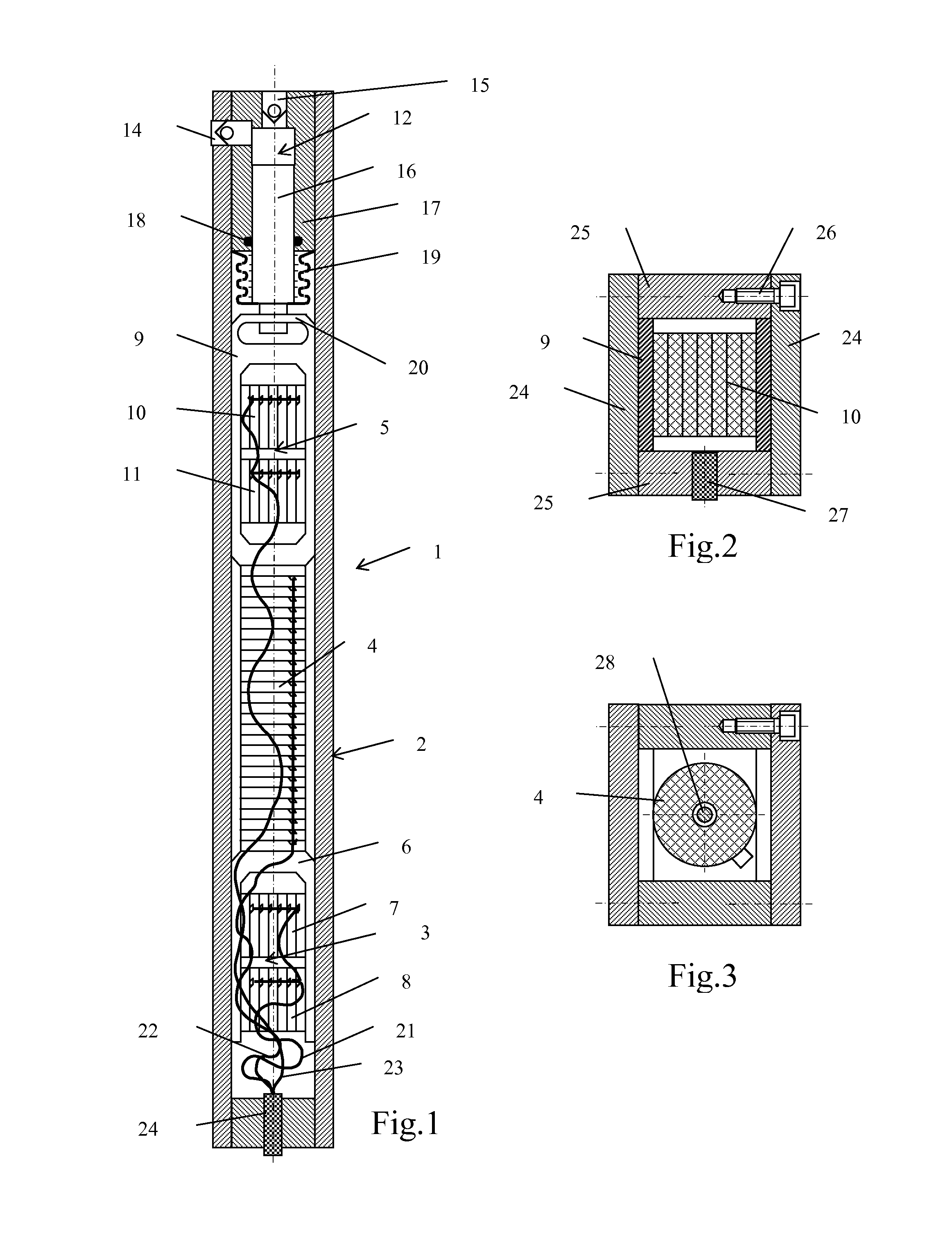

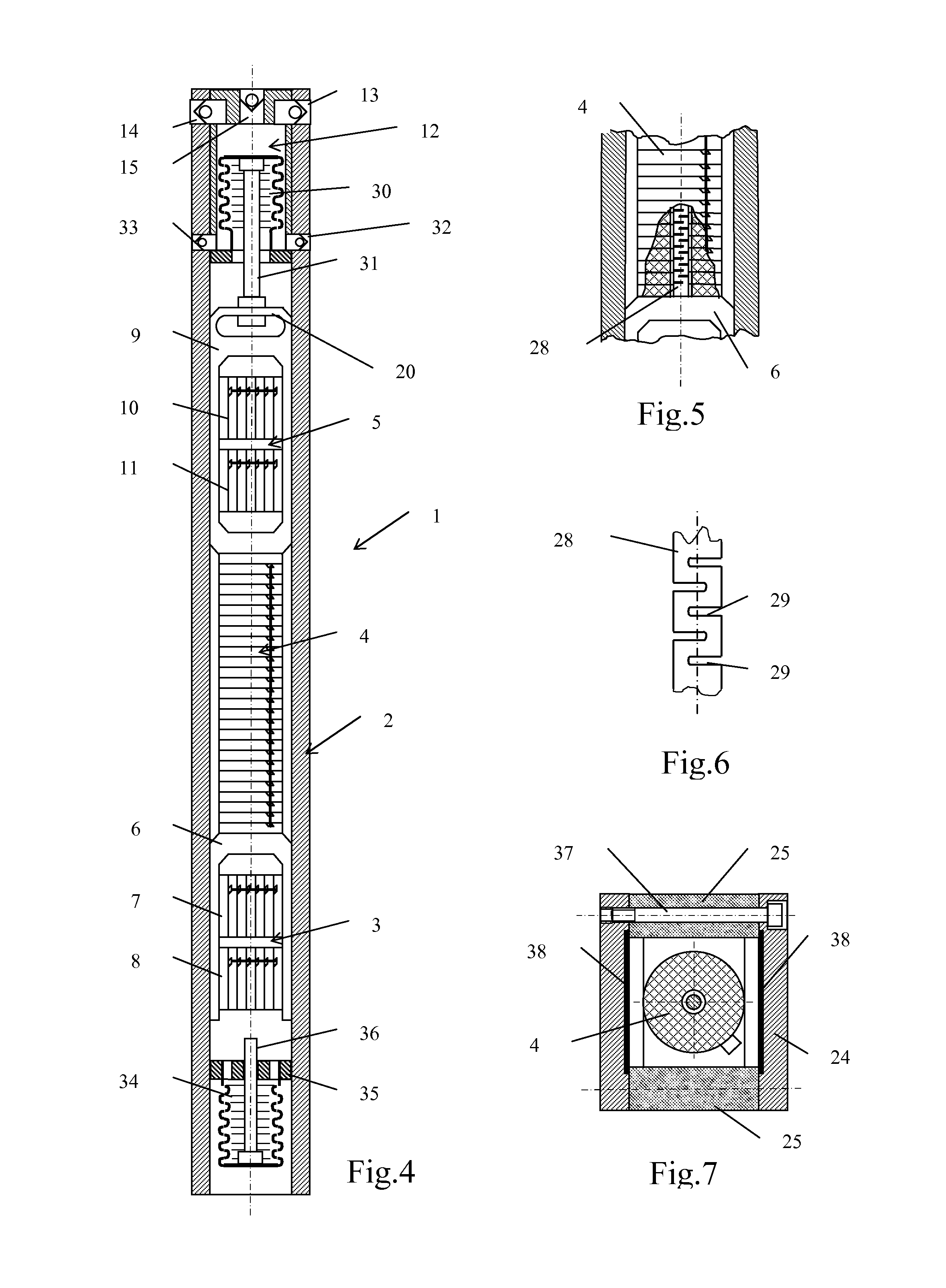

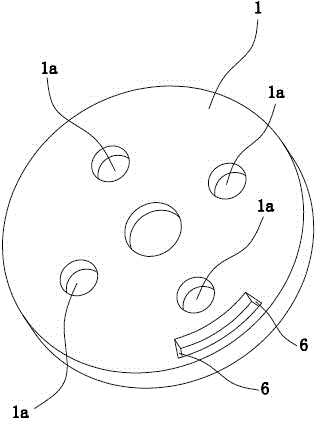

Dissymmetrically-arranged single-piezoelectric stack driving type bidirectional rotary inertia actuator

ActiveCN107222126AImprove output performanceClosely connectedPiezoelectric/electrostriction/magnetostriction machinesInterference fitEngineering

The invention relates to a dissymmetrically-arranged single-piezoelectric stack driving type bidirectional rotary inertia actuator. The actuator comprises an upper end cover, a bearing, an output shaft, a rotary round disc and an actuating mechanism, wherein the actuating mechanism is integratedly processed and is dissymmetrically arranged about a center of a diamond ring in the actuating mechanism, a piezoelectric stack is in interference fit with the interior of the diamond ring along an axial direction, two side planes of the diamond ring are respectively and rigidly connected with L-shaped lever amplification mechanisms along the axial direction, one end of an axial rod piece of each L-shaped lever amplification mechanism is connected with an installation table by a flexible hinge, the other end of the axial rod piece is fixedly connected with a horizontal rod piece, a friction foot is processed on the horizontal rod piece in a protruding way, the rotary round disc is horizontally arranged above the friction foot of the actuating mechanism, the output shaft is arranged at in disc center of an upper surface of the rotary round disc and is connected with the upper end cover by the bearing, the upper end cover is in a spindle shape, and through holes are formed in two ends of the upper end cover and are tightly connected with the actuating mechanism at a bottom end by bolts. The actuator is small in size and novel in structure, and high-accuracy bidirectional rotation motion can be stably achieved only by driving a single piezoelectric stack.

Owner:西安朗威科技有限公司

Bolt-hole cap for bolt hole in linear rail

ActiveUS20140199133A1Connection securityHigh strengthRemovable ornamentalLinear bearingsMechanical engineeringEngineering

Owner:CHIEFTECH PRECISION

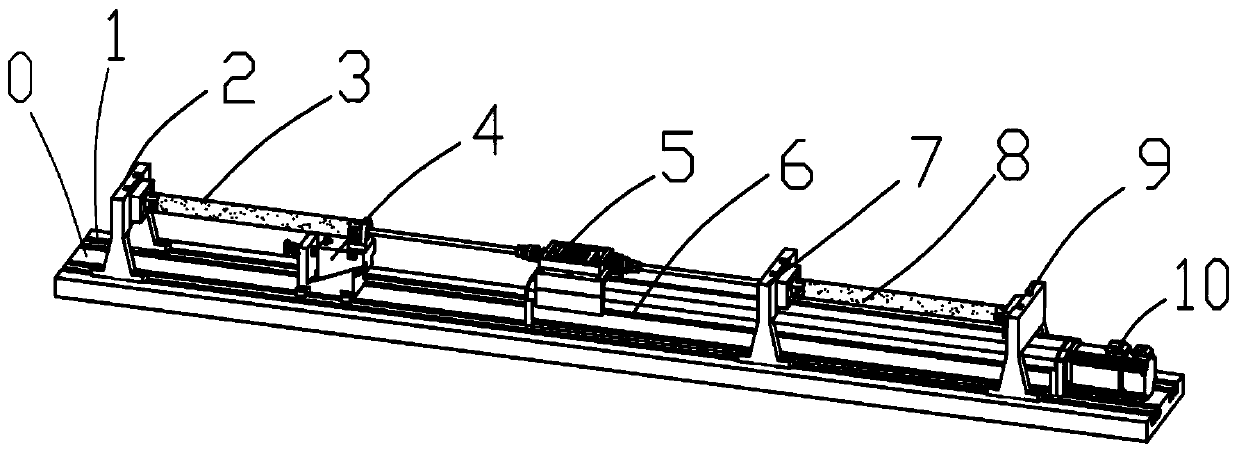

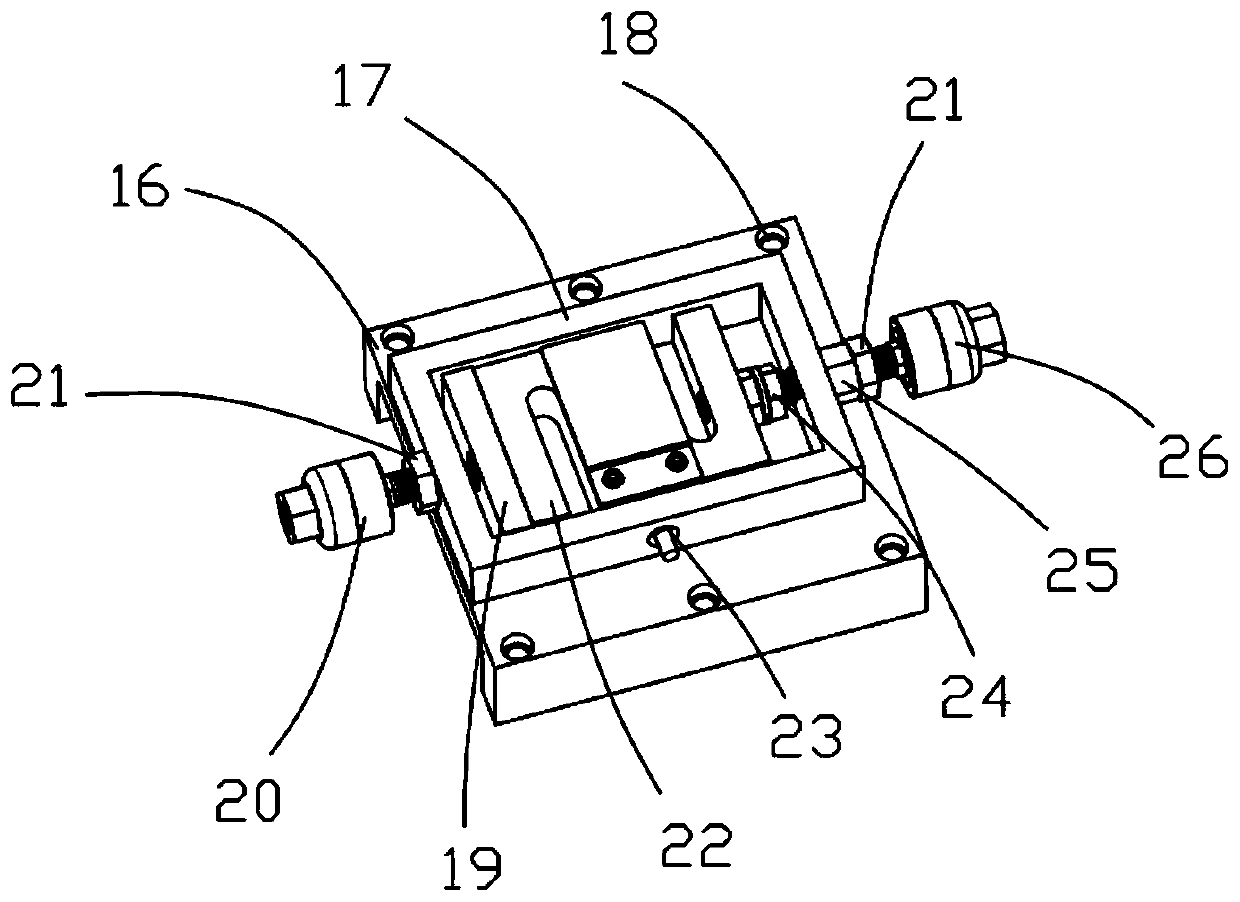

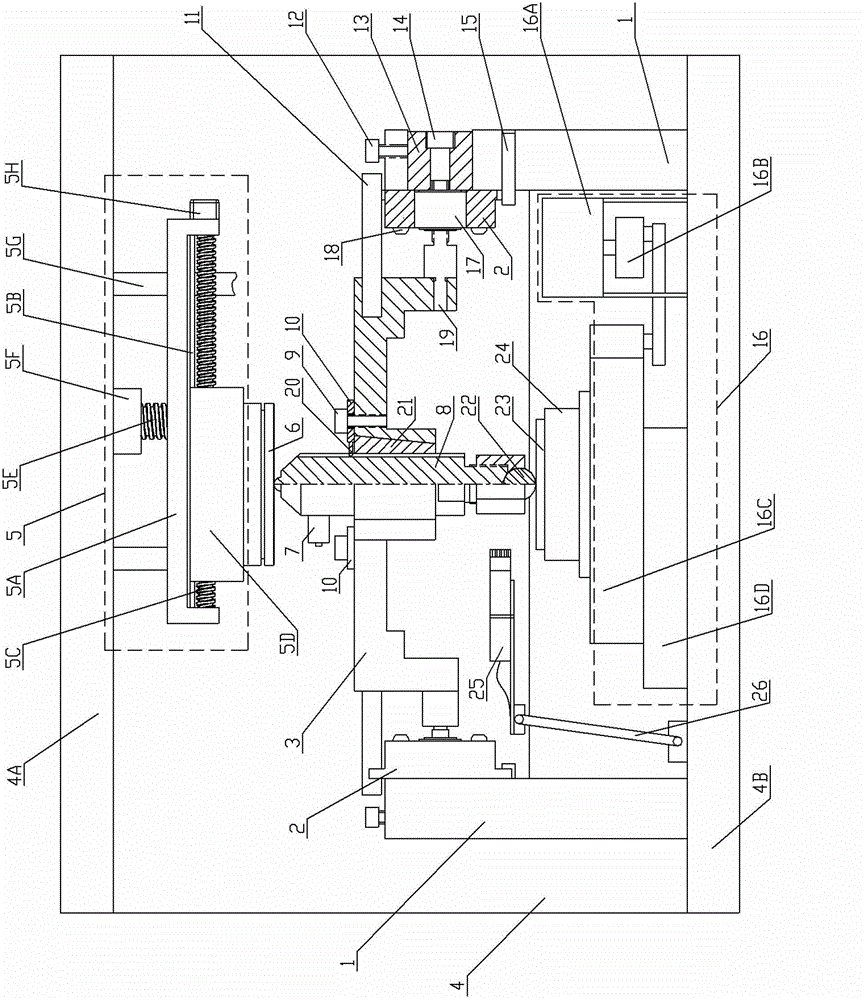

Air cylinder friction force testing device and method

ActiveCN110779648AReliable frictionHigh friction precisionApparatus for force/torque/work measurementControl systemEngineering

The invention provides an air cylinder friction force testing device and method. The air cylinder friction force testing device comprises an installation platform, a motion transmission part, a connecting assembly, a tested part, a supporting part and an air cylinder pressure control system. Three air cylinders with the same piston acting areas of rod cavities and rodless cavities are selected; the two air cylinders are oppositely arranged; and the rod cavities and rodless cavities of the two air cylinders are communicated with each other and externally connected with an air tank. With a normally-closed quick switch valve, the pressure of the air tank is made to be a constant value based on a corresponding control algorithm; pressures applied to the pistons of the two cylinders by compressed air can be cancelled mutually; and a force measured directly by a tension and pressure sensor is the sum of friction forces of two cylinders. On the basis of the same method, the sums of cylinder friction forces under relative installation of two of the three cylinders are measured three times. And then a ternary linear equation set is solved to calculate friction forces of all cylinders. The air cylinder friction force testing device and method have high measurement precision and universality.

Owner:JIANGSU UNIV

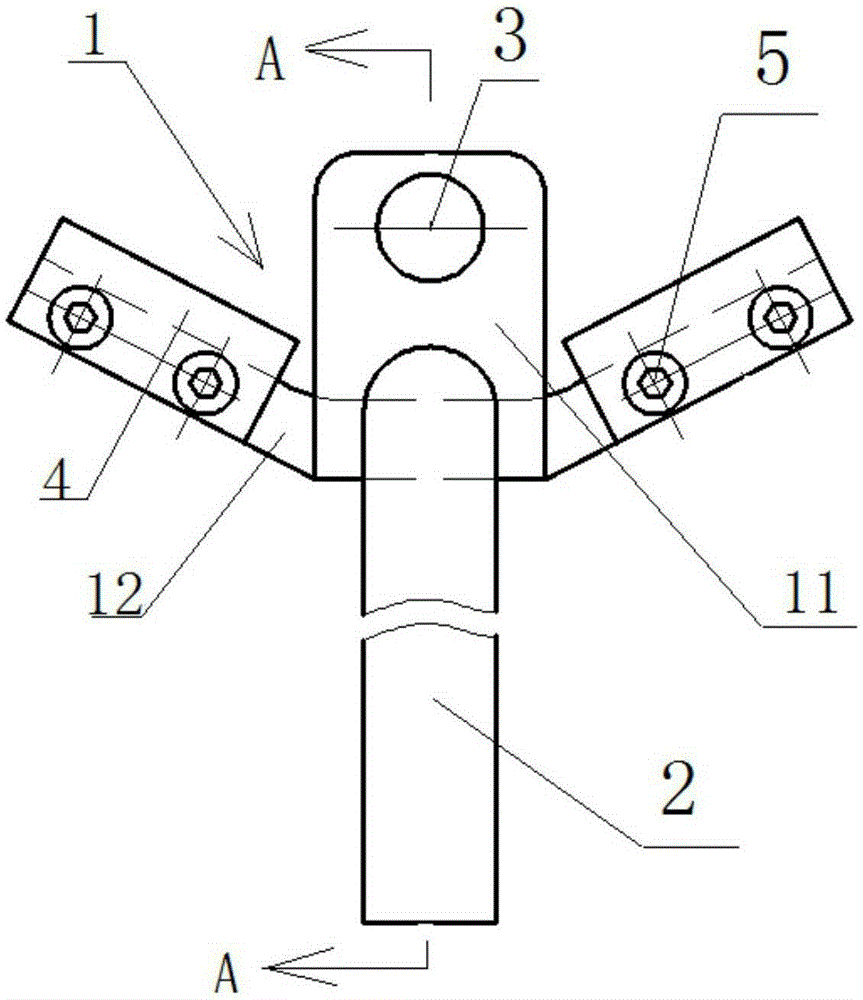

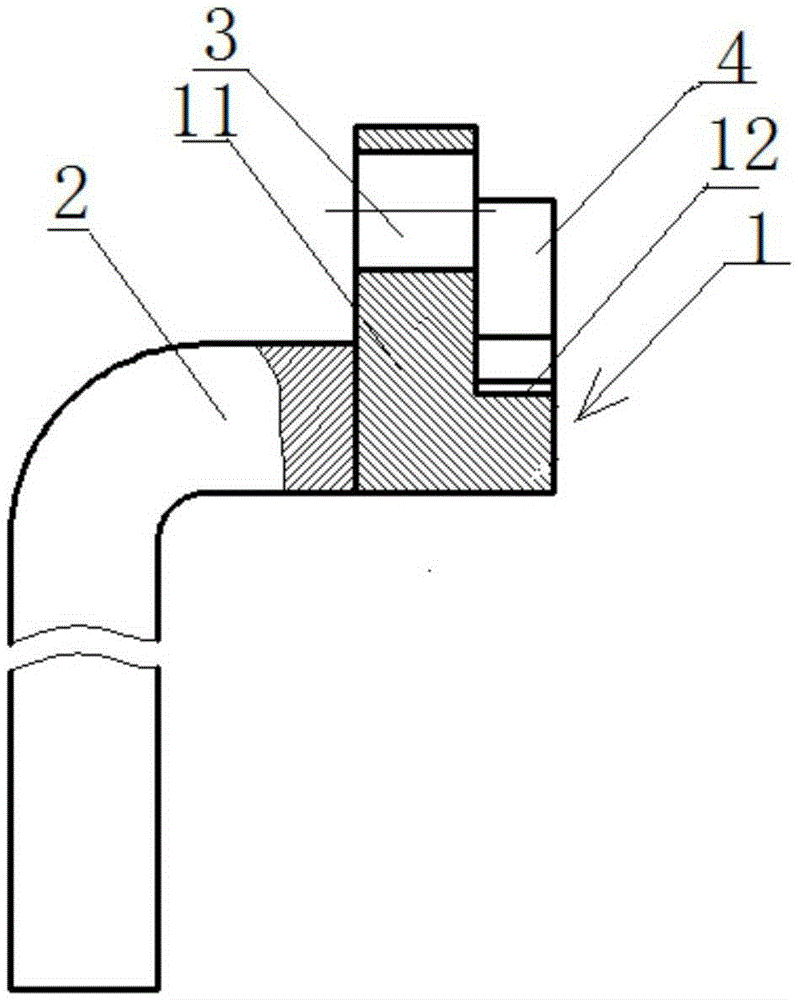

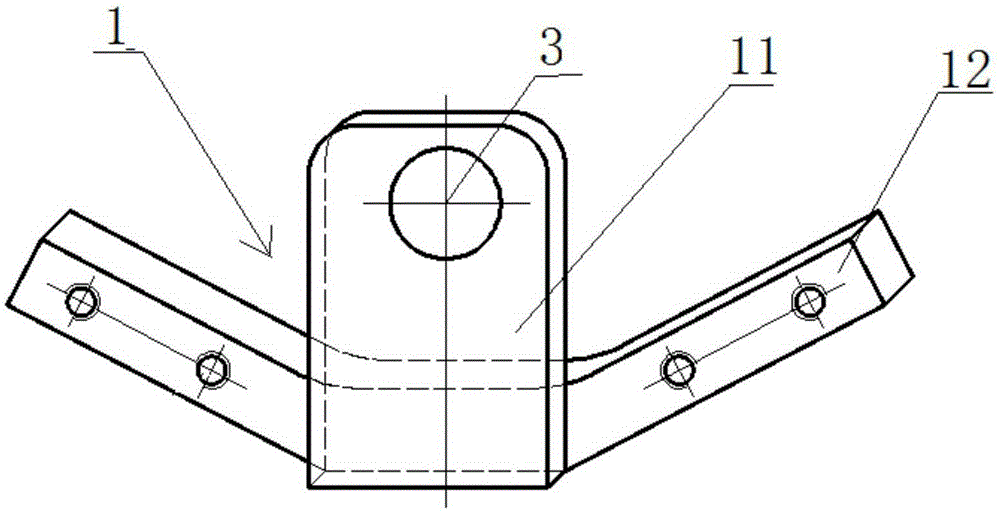

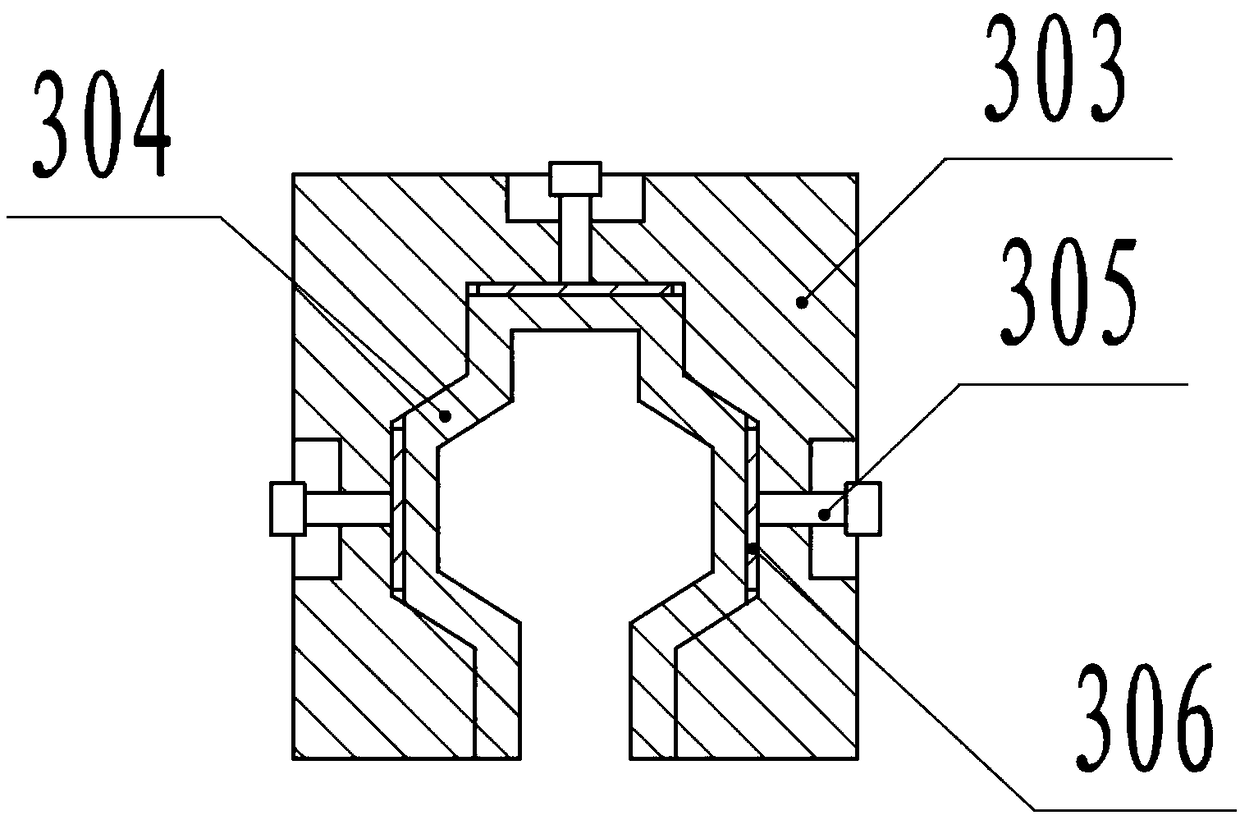

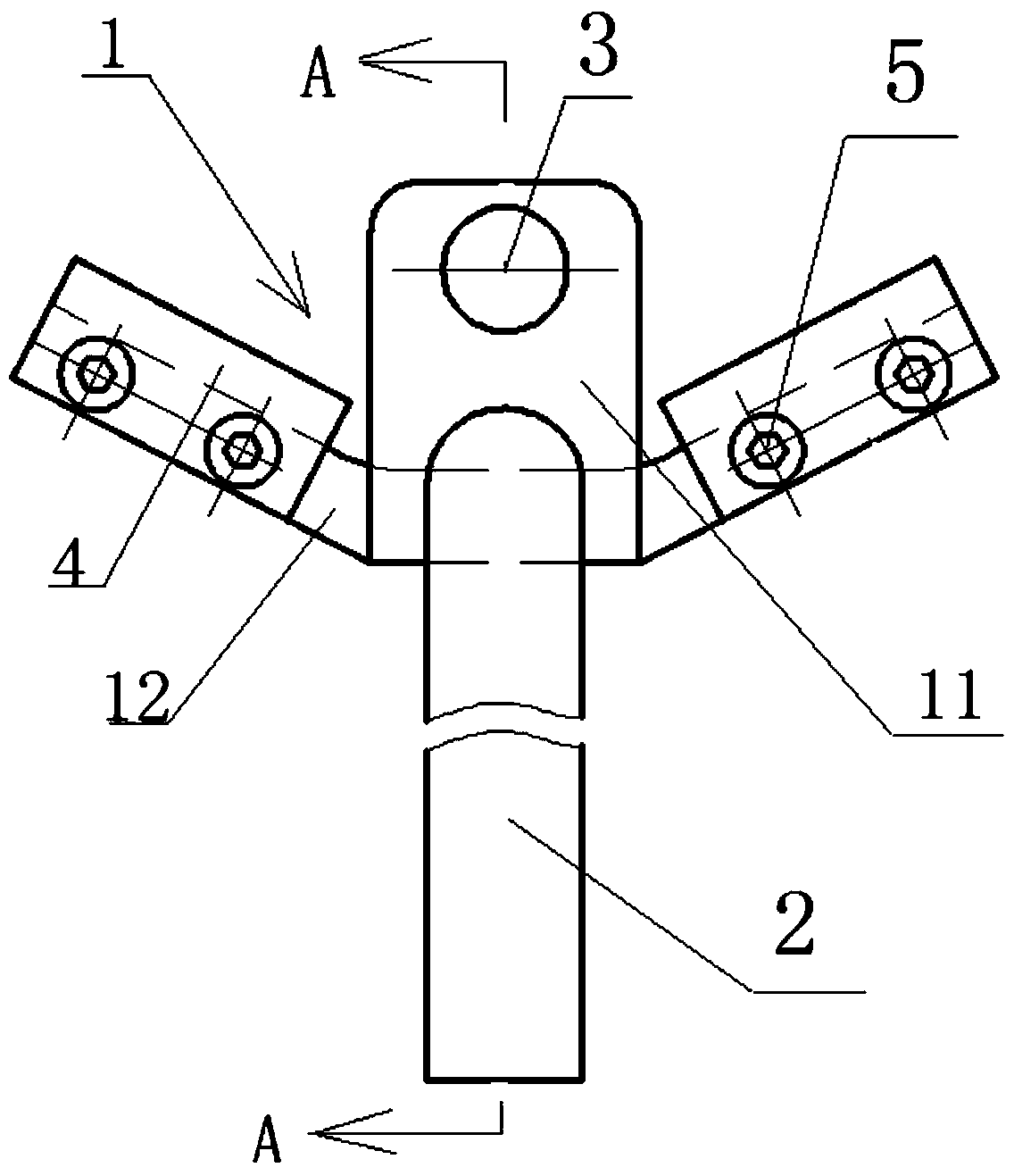

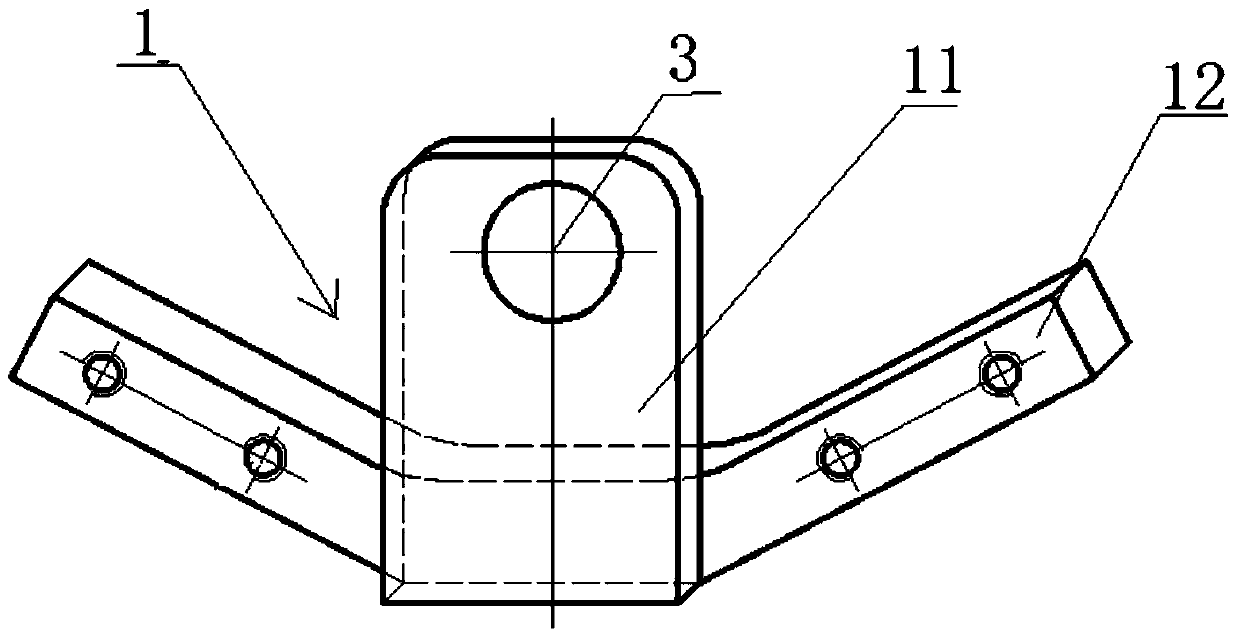

Crankshaft rotation tool and method for rotating crankshaft

ActiveCN105258667ASimple structureEasy to useMeasurement devicesReciprocating piston enginesElastic componentEngineering

The present invention discloses a crankshaft rotation tool, comprising a locating block and a handle connected with the locating block, wherein the locating block comprises a main locating block and two auxiliary locating blocks arranged at two sides of the main locating block, each auxiliary locating block is provided with an elastic component used for being tightly contacted with an excircle of a big end of a crankshaft, and the main locating block is provided with a locating hole used for cooperating with a locating pin at the end face of the big end of the crankshaft. The present invention aims to provide the crankshaft rotation tool which is simple in structure, convenient and reliable in use, and capable of forwards and reversely rotating the crankshaft, at the same time, the present invention also provides a method for rotating the crankshaft by adopting the crankshaft rotation tool.

Owner:GUANGXI YUCHAI MASCH CO LTD

Friction device for rolling up curtains and the like

ActiveUS7246648B2Stable positionEasy constructionDoor/window protective devicesPower-operated mechanismFriction effectCoupling

Owner:SILENT GLISS ITAL SRL

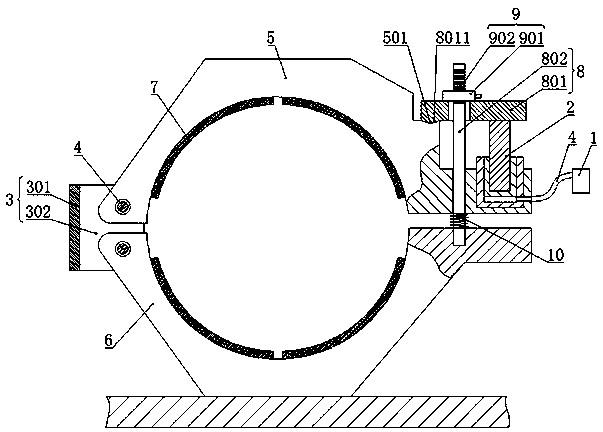

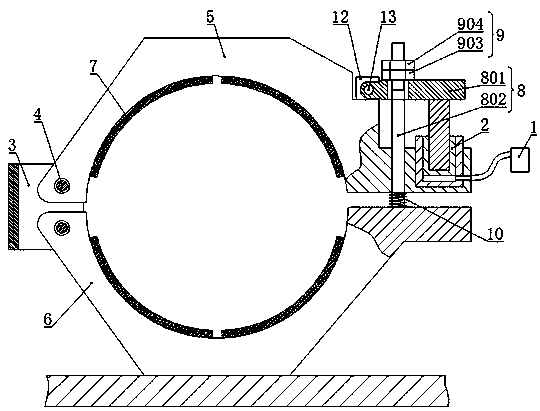

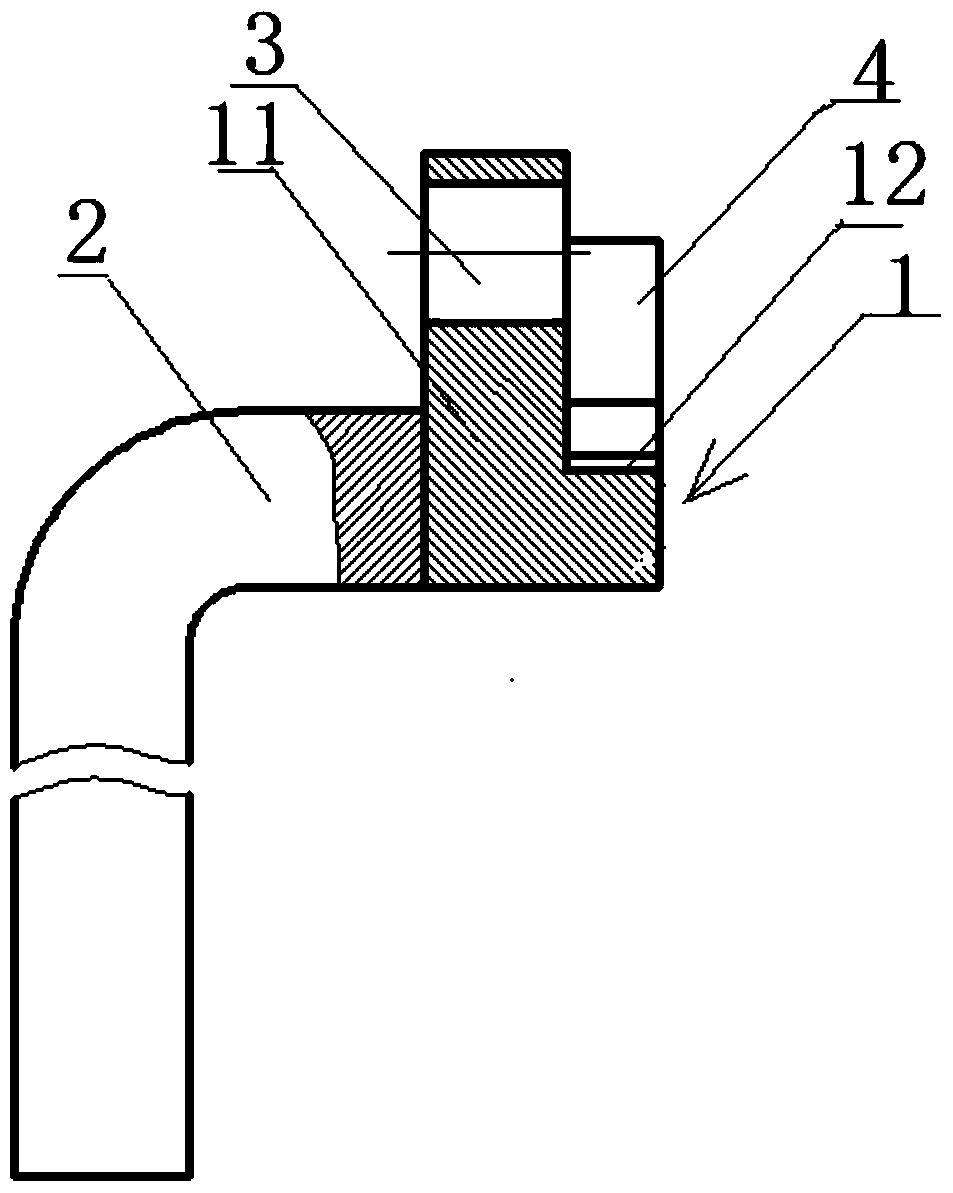

Fishing boat stern shaft braking device

PendingCN109163036AReliable stopImprove braking efficiencyBraking membersDrum brakesEngineeringSEMI-CIRCLE

The invention discloses a fishing boat stern shaft braking device to solve the problems that an existing fishing boat stern shaft is long in the inertia braking time and is high in reverse brake transmission component damage. The fishing boat stern shaft braking device comprises a hydraulic pump station, a hydraulic oil cylinder, a mounting plate assembly, a semi-circle upper hoop body and a lowerhoop body. The upper hoop body and the lower hoop body encircle to form an embracing shape. Friction pieces are respectively arranged on the opposite faces of the upper hoop body and the lower hoop body. The connecting ends of the upper hoop body and the lower hoop body are respectively rotatably connected with the mounting plate assembly through connecting pieces. An executing mechanism is arranged between the locking ends of the upper hoop body and the lower hoop body. A cylinder body of the hydraulic oil cylinder is fixed to the locking end of the upper hoop body. A piston rod of the hydraulic oil cylinder drives the upper hoop body and the lower hoop body to encircle or separate through the executing mechanism. The semi-circle upper hoop body and the lower hoop body encircle to form an embracing stem shaft in an embracing shape. Friction braking is achieved between the friction pieces on the opposite faces and a stopping sleeve at the stem shaft. The braking efficiency is high, and component damage is little.

Owner:HUANGHAI SHIPBUILDING

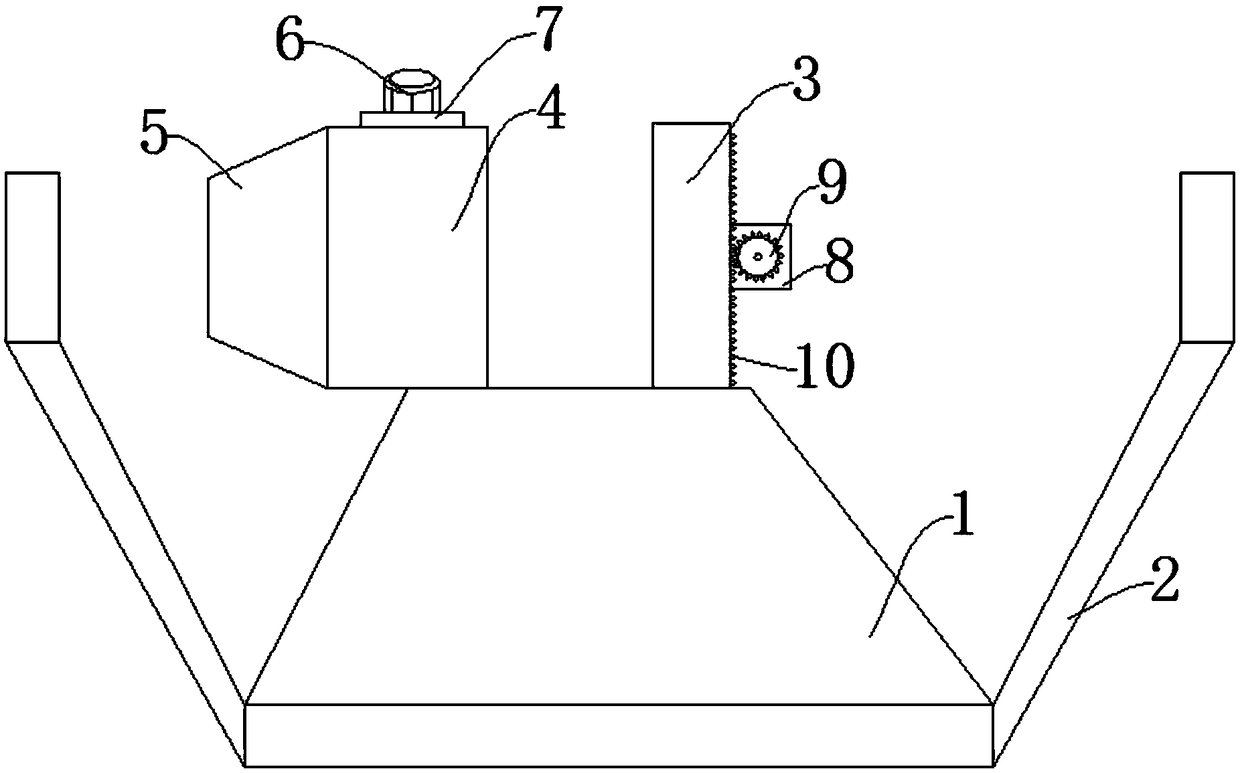

Plastic pipe outer surface cleaning device for processing plastic products

InactiveCN109226111AHigh degree of automationReliable frictionHollow article cleaningRubber materialRolling resistance

The invention discloses a plastic pipe outer surface cleaning device for processing plastic products. The device comprises a base, the top end of the base is provided with a movable seat, the rear endof the movable seat is provided with a mounting seat, the movable seat is fixedly connected with the base through the mounting seat, the innovation of the device lies in the ability to clean the outer surface of a plastic pipe with a simple structural device, and the degree of automation is high; the device is integrally fixed at the upper end of the base, the movable seat can make the plastic pipe member pass through the movable seat and an outer brush holder in turn, the outer surface of the whole plastic pipe is cleaned, for the inside of the movable seat, the principle that a plurality ofrotating shafts cooperate with a rotating body to roll and rub a pipe body is used, a moving motor drives the rotating shafts and the rotating body, so that a pipe member moves inside the movable seat, the rotating body is made of a flexible rubber material, in the case that the diameter of the pipe member is smaller than the diameter of a small end of a limiting hole, pipe members of different diameters can be matched, the friction can be ensured reliably without slipping, the overall structure is simple and compact, and the use is convenient.

Owner:安徽泽泓塑业股份有限公司

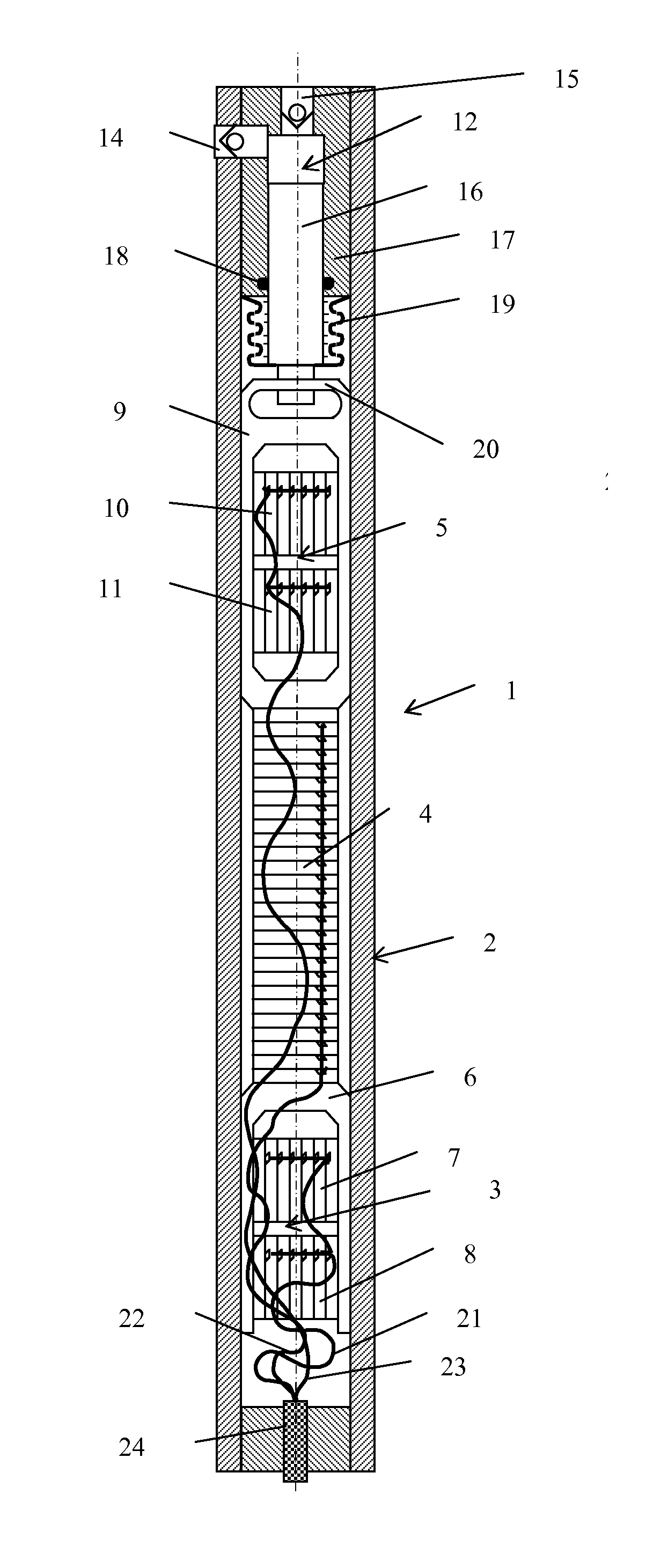

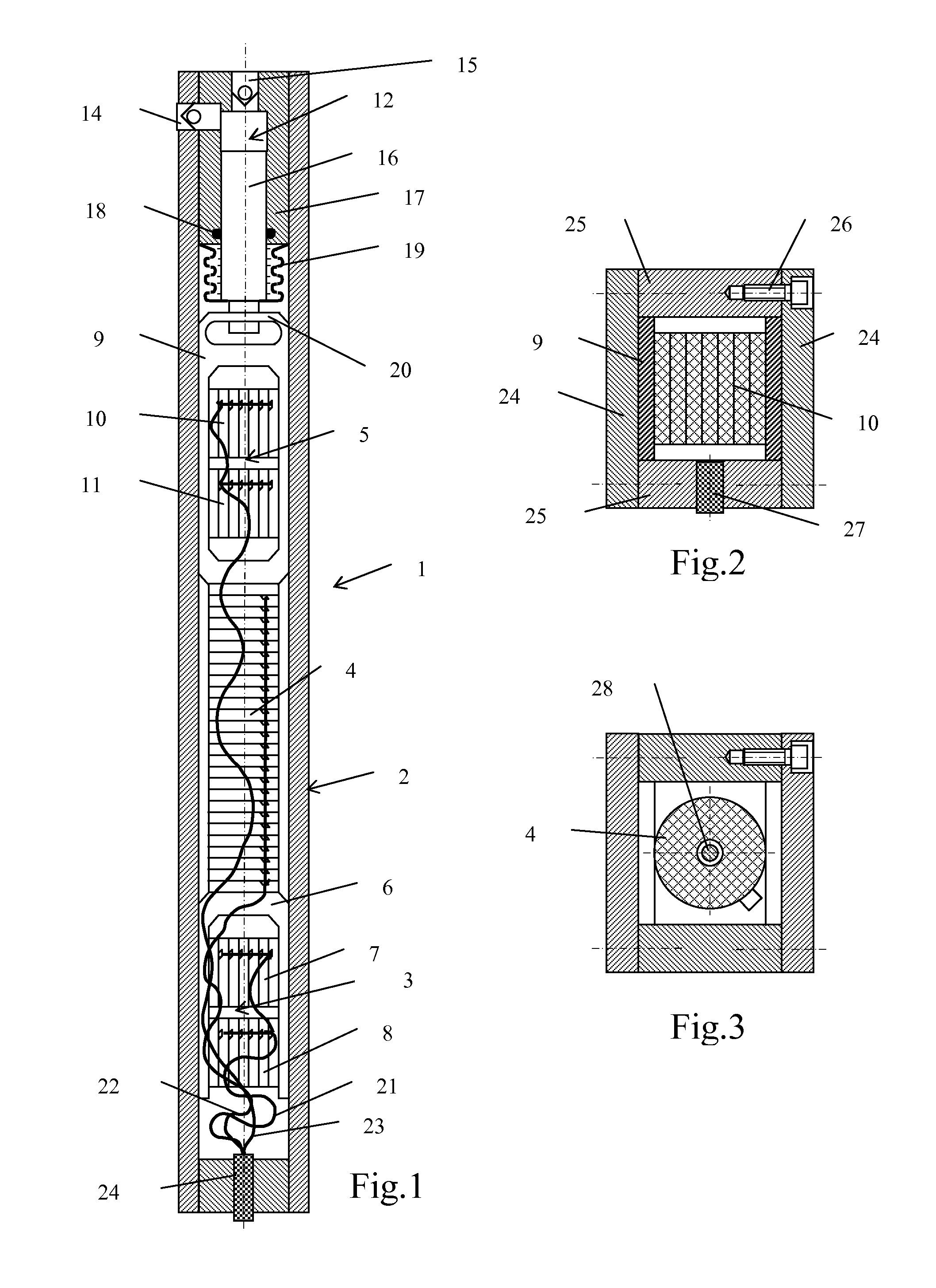

Piezoelectric pump

ActiveUS9273676B2Extended service lifeHigh pressurePumpsPositive-displacement liquid enginesElectricityElectrical impulse

The piezoelectric pump comprises a housing, containing the following components connected in series: a rear piezoelectric clamp section, a piezoelectric extender section and a front piezoelectric clamp section. A displacer of pumped fluid is connected to the front piezoelectric clamp section. Electric pulses accessing at sections from a control station cause said sections to become fixed alternately inside the housing. Under the effect of electric pulses, the piezoelectric extender section moves the displacer step-by-step in one direction. Positive effect achieved by the invention is that of increasing the service life of the piezoelectric pump, expanding the scope of use thereof by increasing the number of fluids that can be pumped and also providing for a greater pressure by preventing contact between the pumped fluid and the friction surfaces of the housing and the piezoelectric clamp sections.

Owner:RENK LIMITED LIABILITY

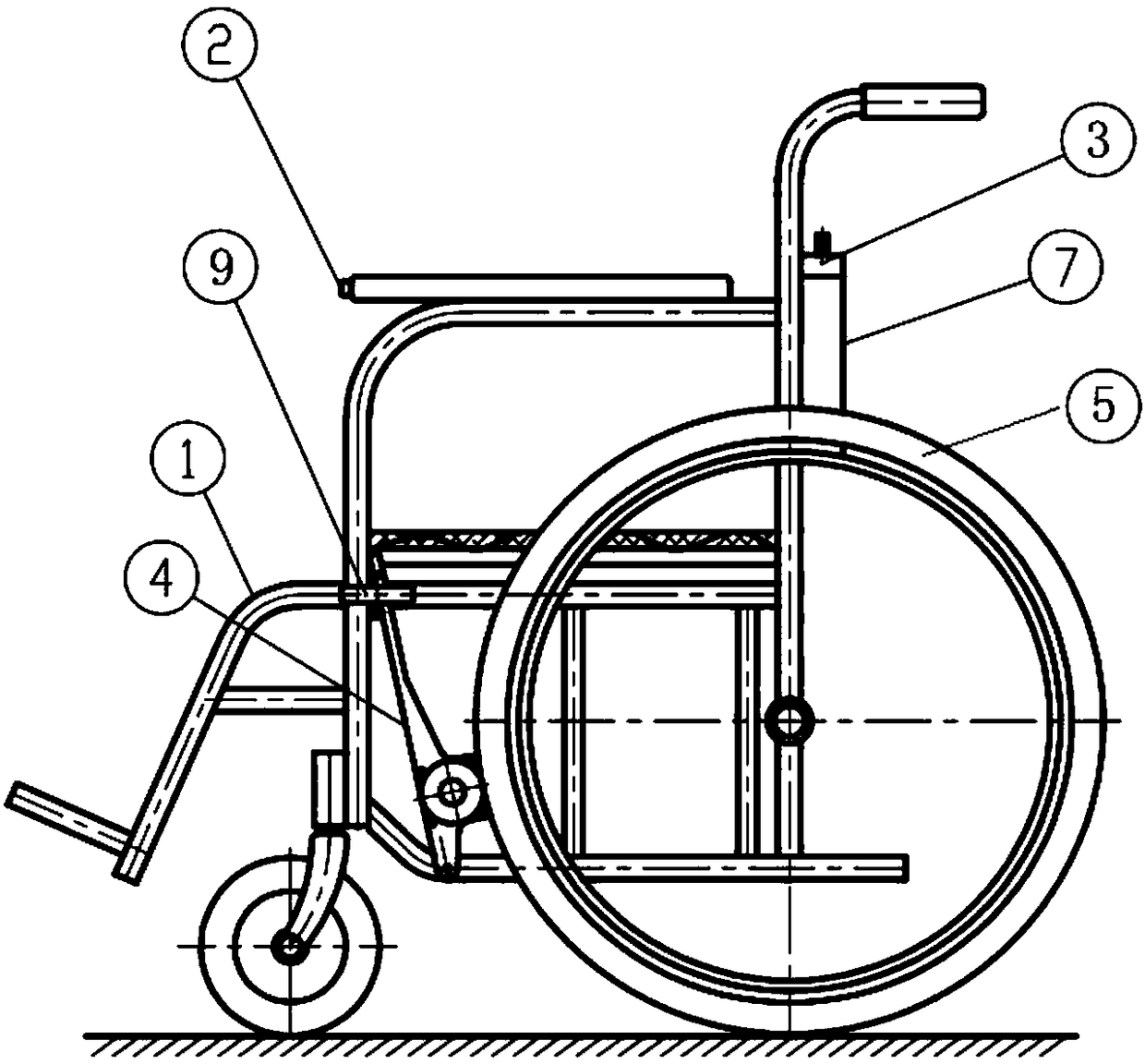

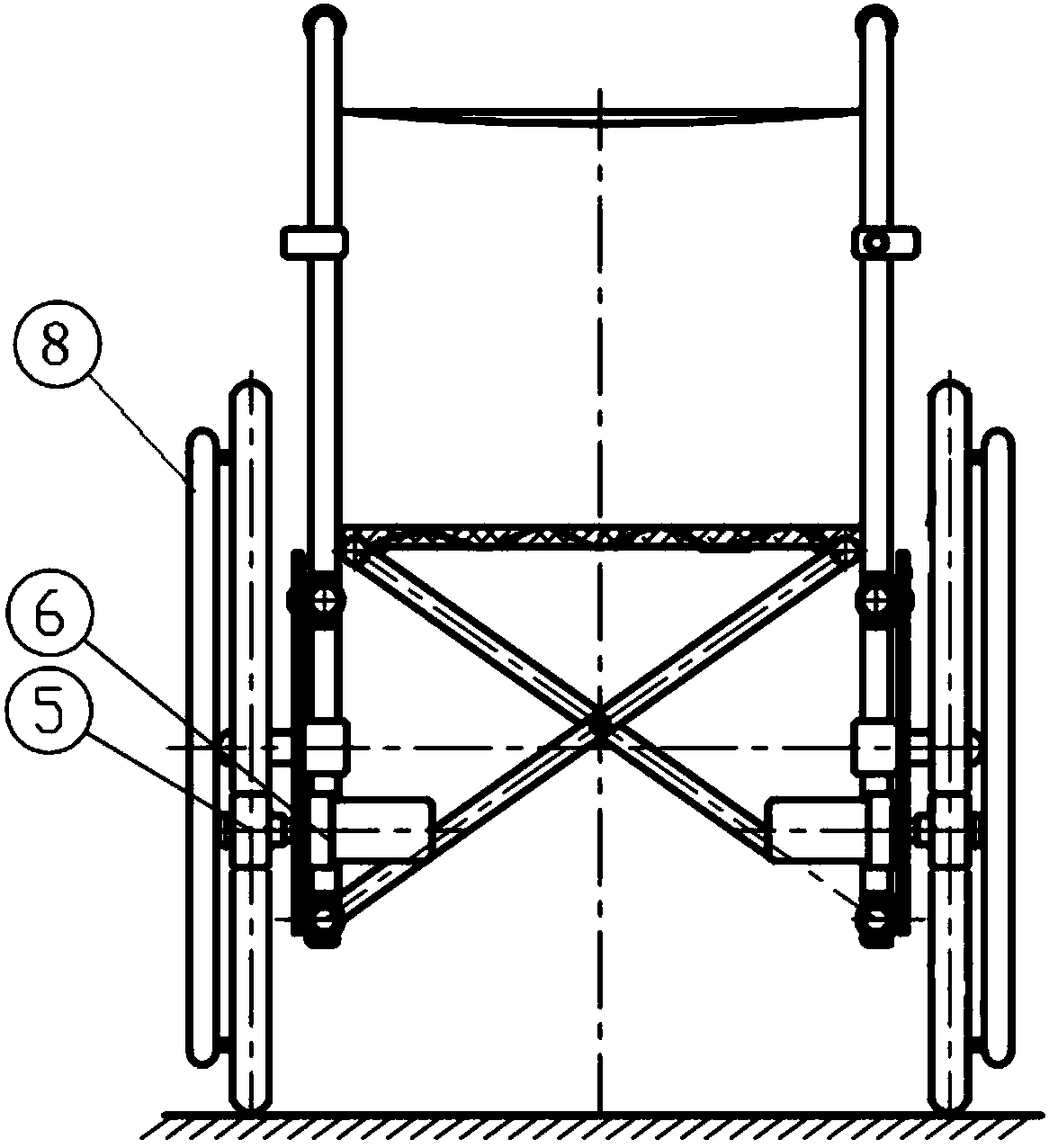

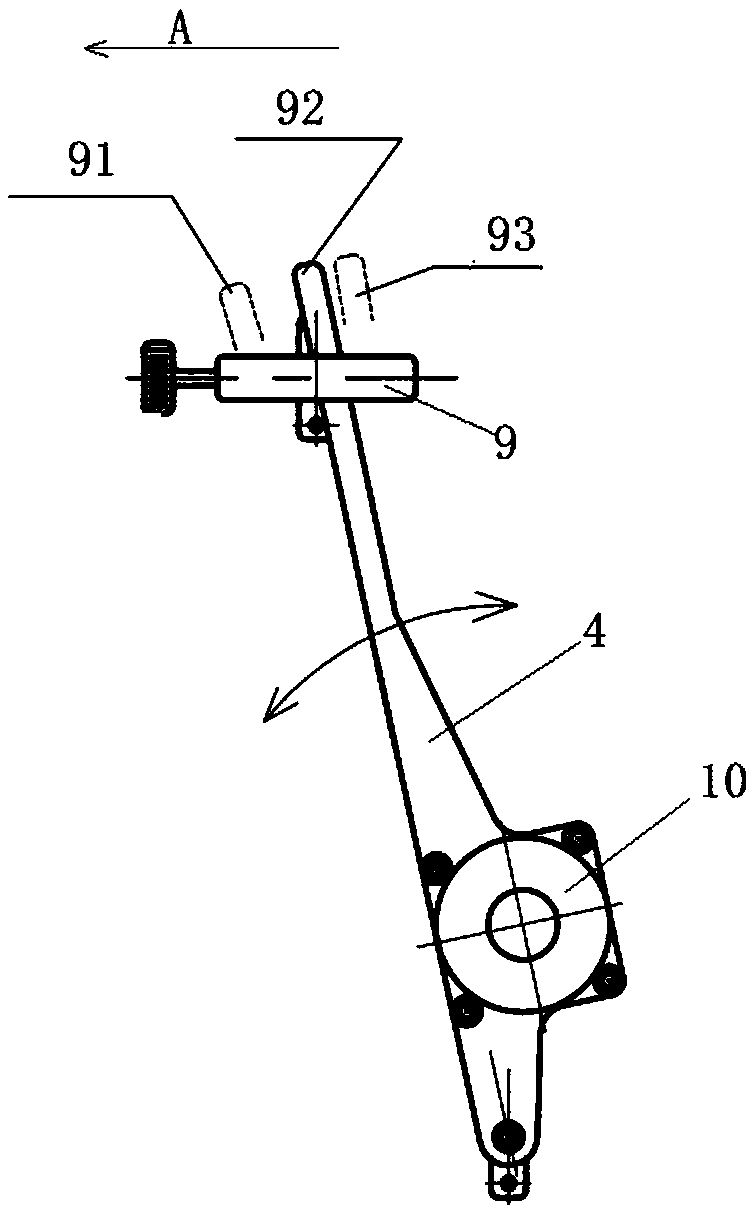

Wheel driving device and electric wheelchair provided with same

The invention relates to a wheel driving device and a wheelchair, in particular to a wheel driving device and an electric wheelchair. The wheel driving device comprises a driving wheel and a motor fordriving the driving wheel to rotate, and the driving wheel is in detachable driving connection with a wheel. The device solves the technical problems that when an equipment battery of a driving wheelin the prior art is out of power, manual pushing resistance is large and pushing wastes efforts. The wheel driving device and the wheelchair provided with the same are further provided. The wheel driving device electrically drives the wheel when there is power and makes riding or pushing need less efforts when the battery is out of power.

Owner:乔子凡

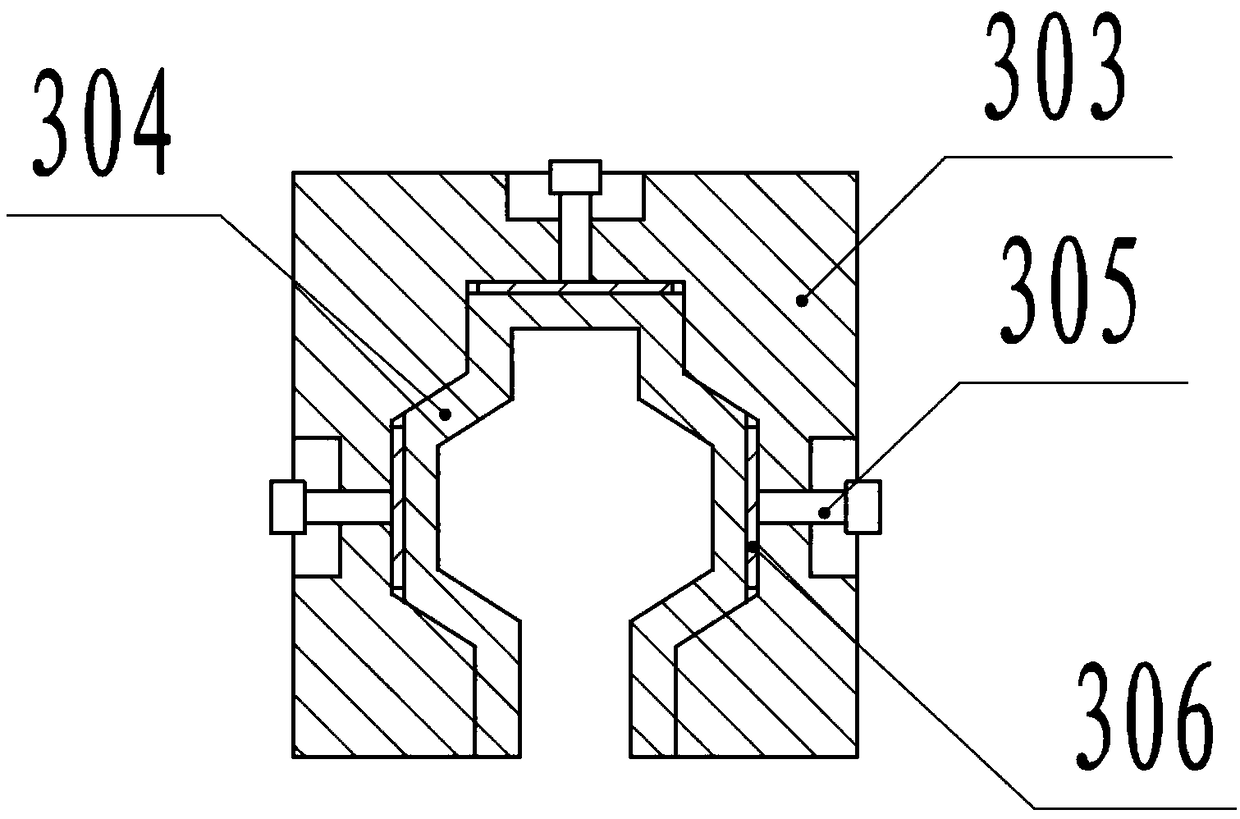

Friction sliding block for high-rise escape device

InactiveCN109125964AAvoid scratchesImprove carrying capacityBuilding rescueEngineeringMechanical engineering

Owner:GUIZHOU UNIV

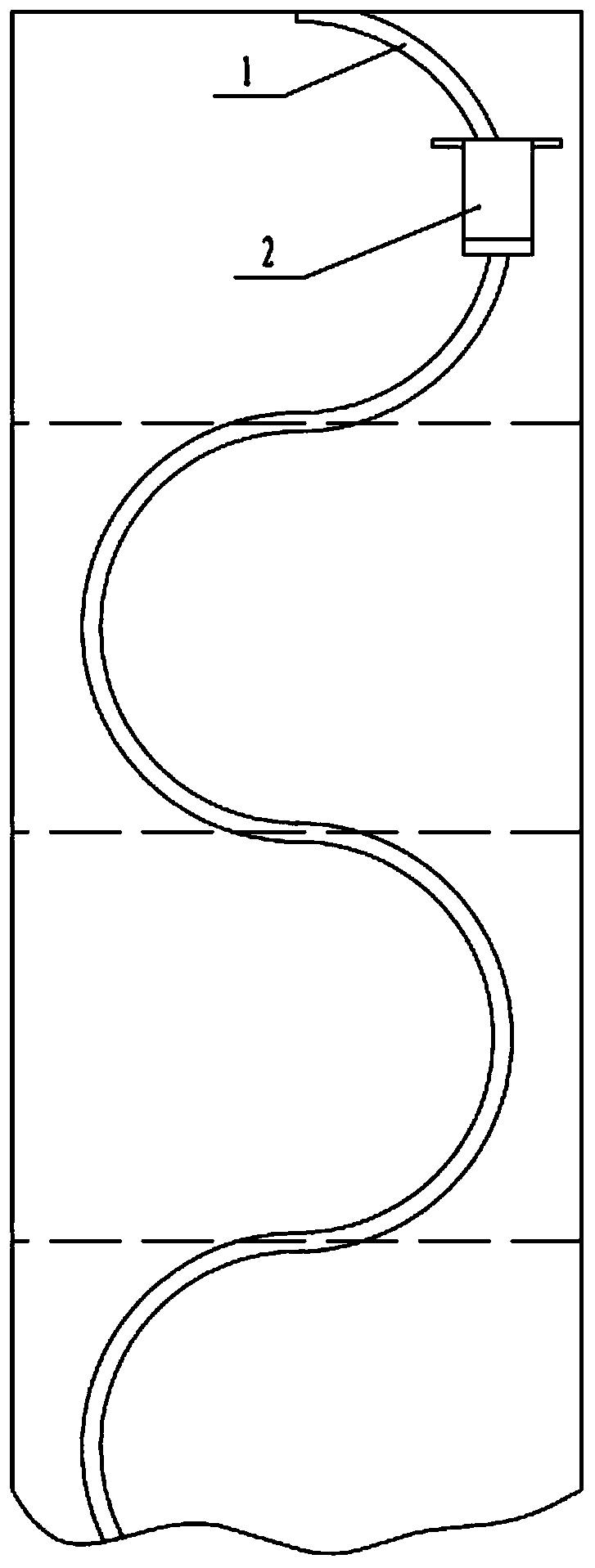

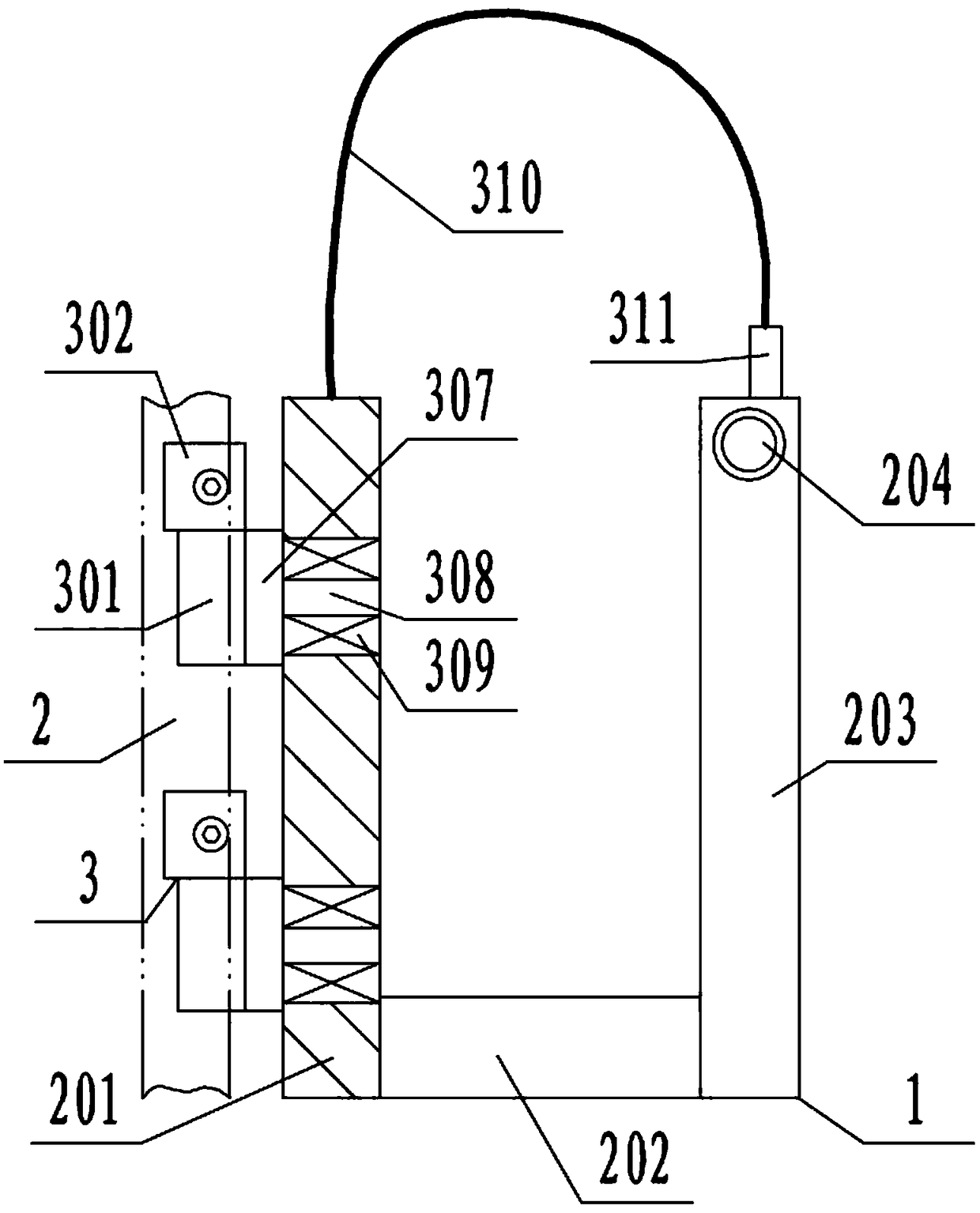

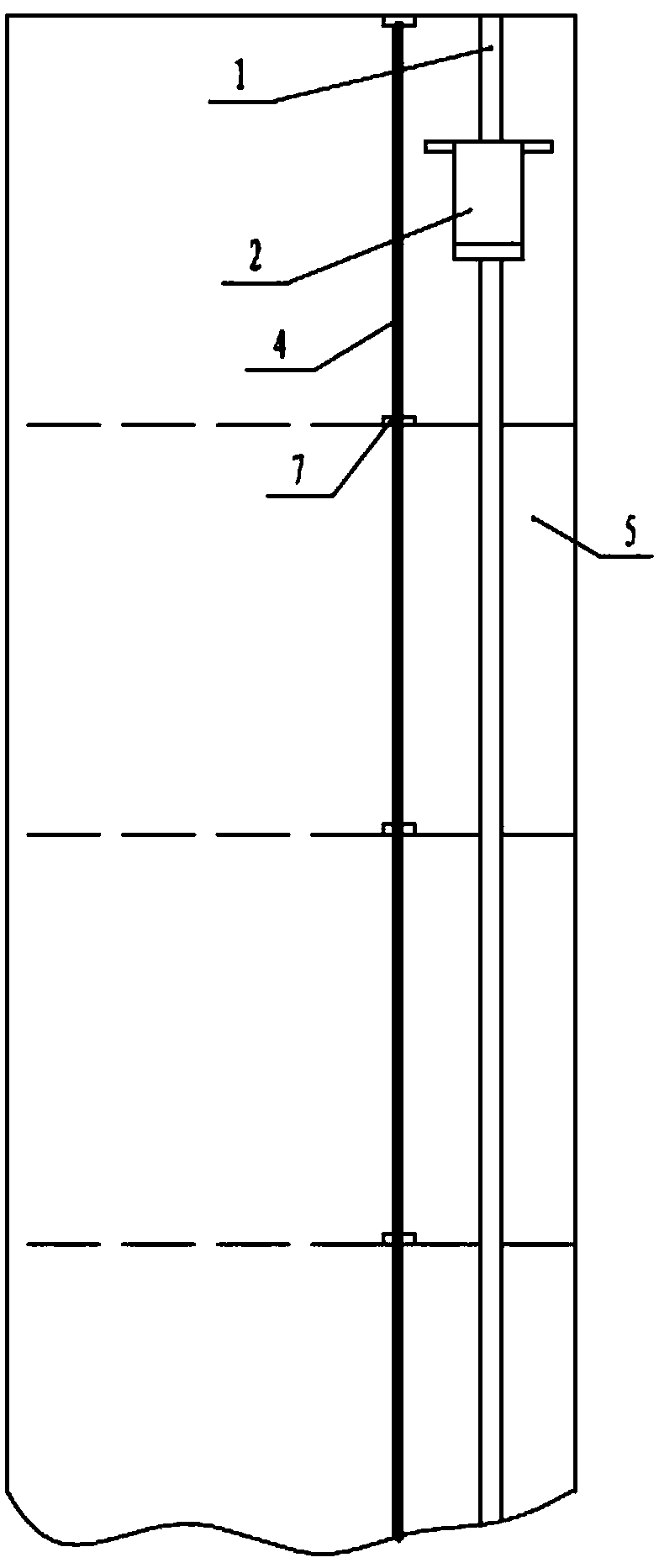

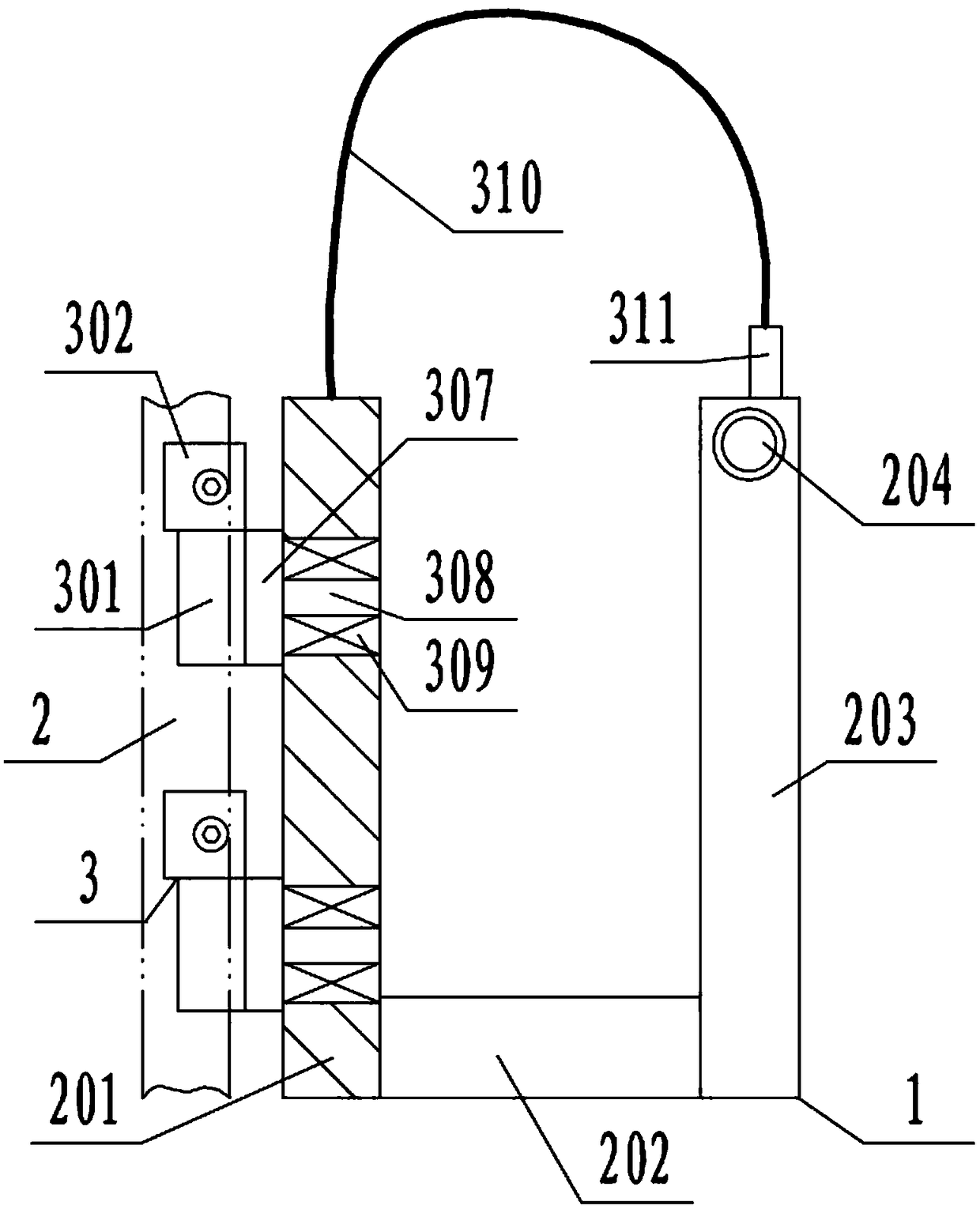

Vertical high-rise escape device and usage method thereof

PendingCN109011231ASave time and effortOvercome psychological stressBuilding rescueEngineeringHigh rise

The invention discloses a vertical high-rise escape device. The vertical high-rise escape device comprises a vertical linear track and a track trolley which are installed on the outer portion of a high-rise wall, wherein the track trolley is tightly connected to the linear track through a friction sliding block, and when the bearing gravity of the track trolley is greater than borne friction force, the track trolley slides downward. The vertical high-rise escape device further comprises a stay cord installed beside the vertical linear track. According to the vertical high-rise escape device, the escape device generates friction force on the linear track so as to descend at a uniform speed or in a deceleration mode, automatic falling is achieved without manual control, time and labor are saved, and besides, people do not need to worry, so that the mental tension issue is solved, In addition, by means of the stay cord, on the one hand, the braking function can be achieved and the speed can be controlled conveniently, and on the other hand, the operation safety is higher. The vertical high-rise escape device further has the characteristics of simple structure and low cost.

Owner:GUIZHOU UNIV

Crankshaft turning tool and method of turning a crankshaft

ActiveCN105258667BSimple structureEasy to useMeasurement devicesReciprocating piston enginesElastic componentEngineering

The present invention discloses a crankshaft rotation tool, comprising a locating block and a handle connected with the locating block, wherein the locating block comprises a main locating block and two auxiliary locating blocks arranged at two sides of the main locating block, each auxiliary locating block is provided with an elastic component used for being tightly contacted with an excircle of a big end of a crankshaft, and the main locating block is provided with a locating hole used for cooperating with a locating pin at the end face of the big end of the crankshaft. The present invention aims to provide the crankshaft rotation tool which is simple in structure, convenient and reliable in use, and capable of forwards and reversely rotating the crankshaft, at the same time, the present invention also provides a method for rotating the crankshaft by adopting the crankshaft rotation tool.

Owner:GUANGXI YUCHAI MASCH CO LTD

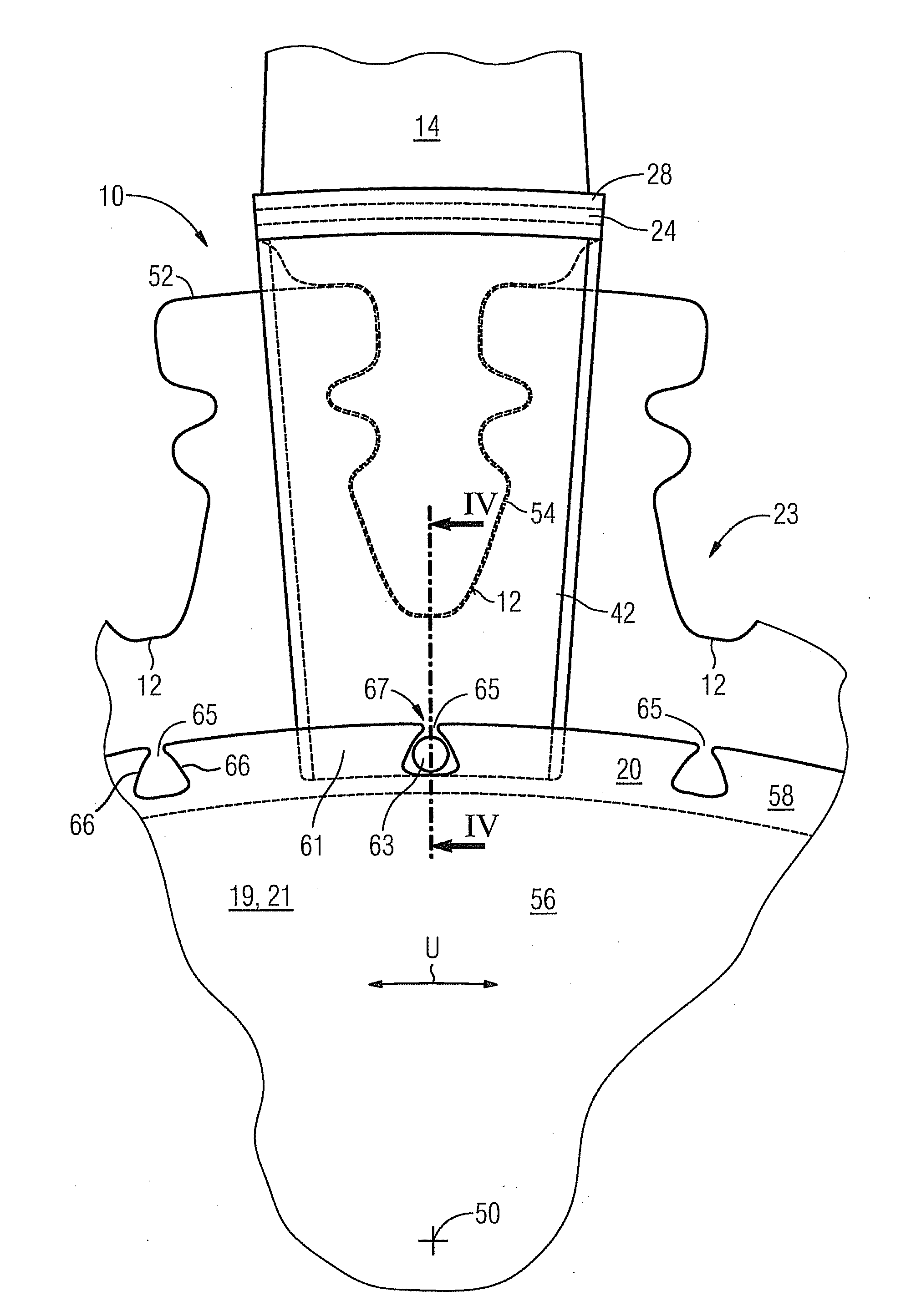

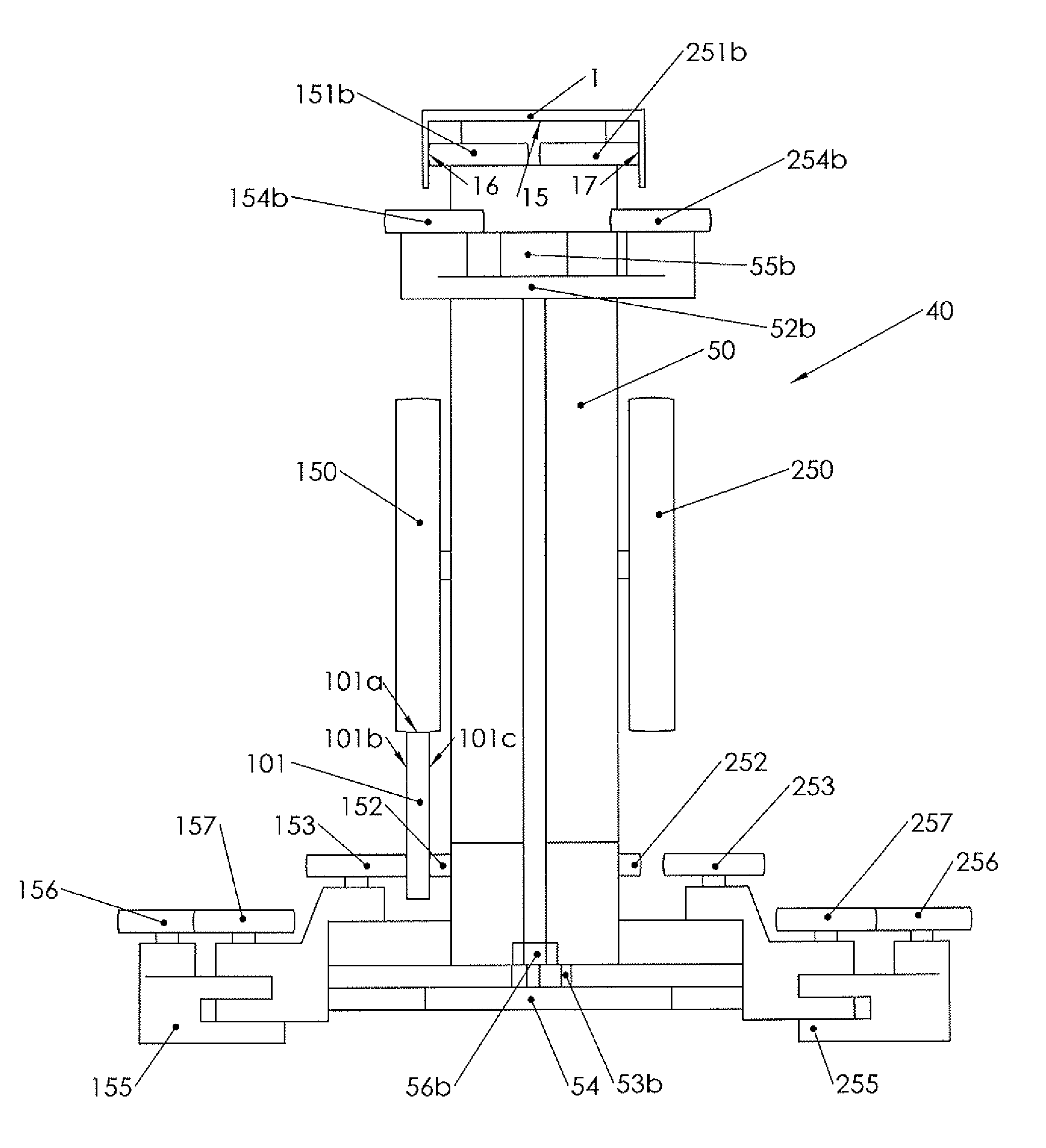

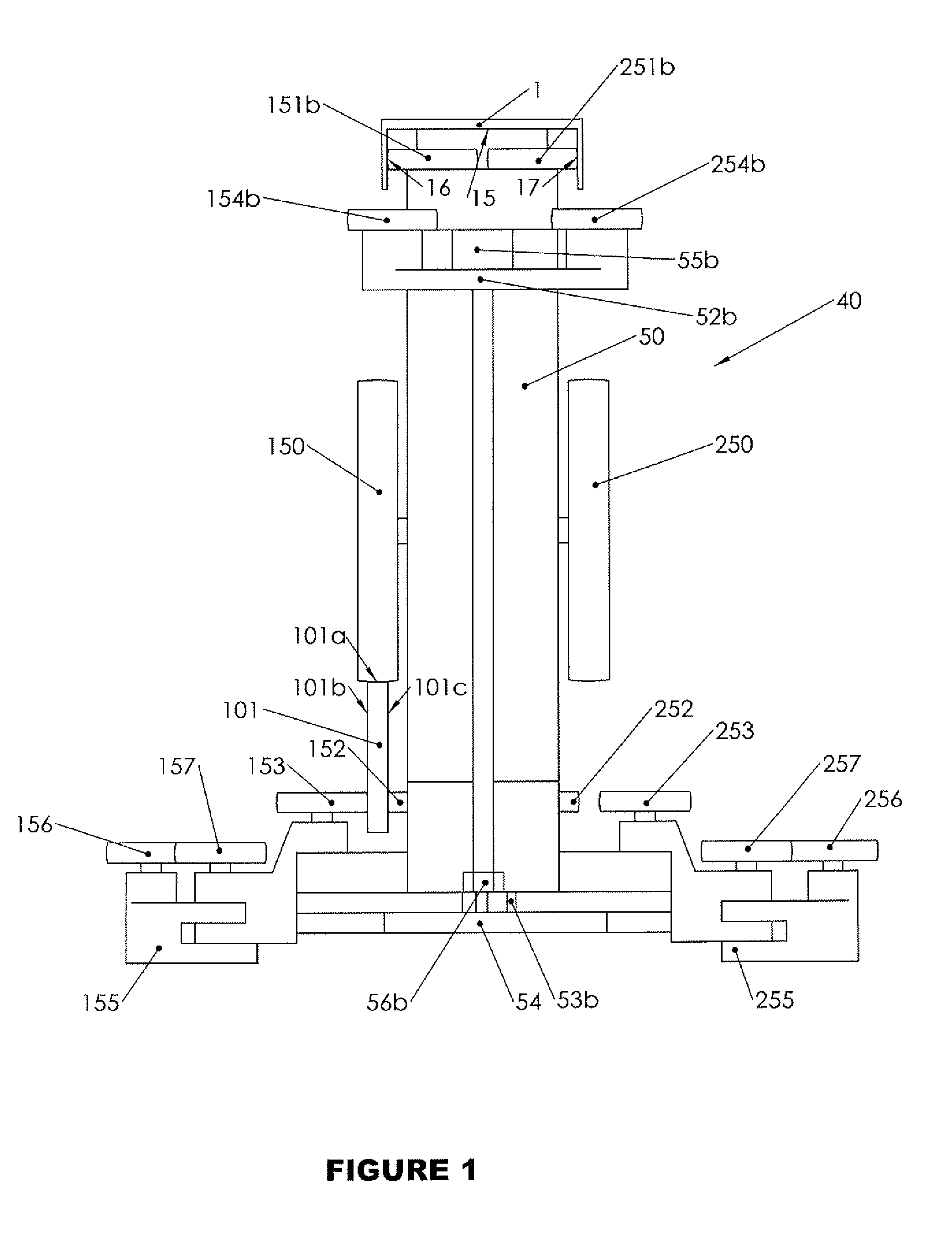

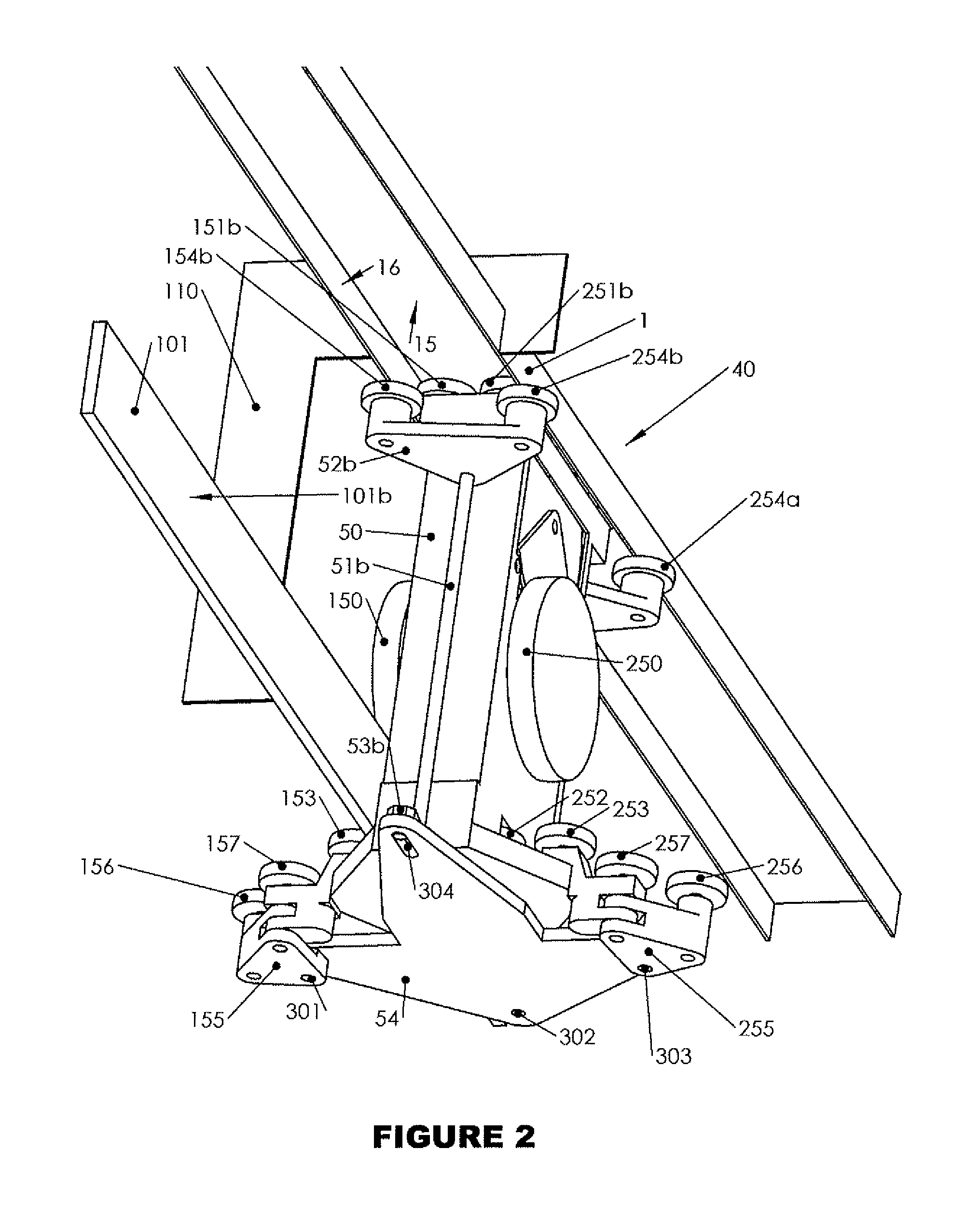

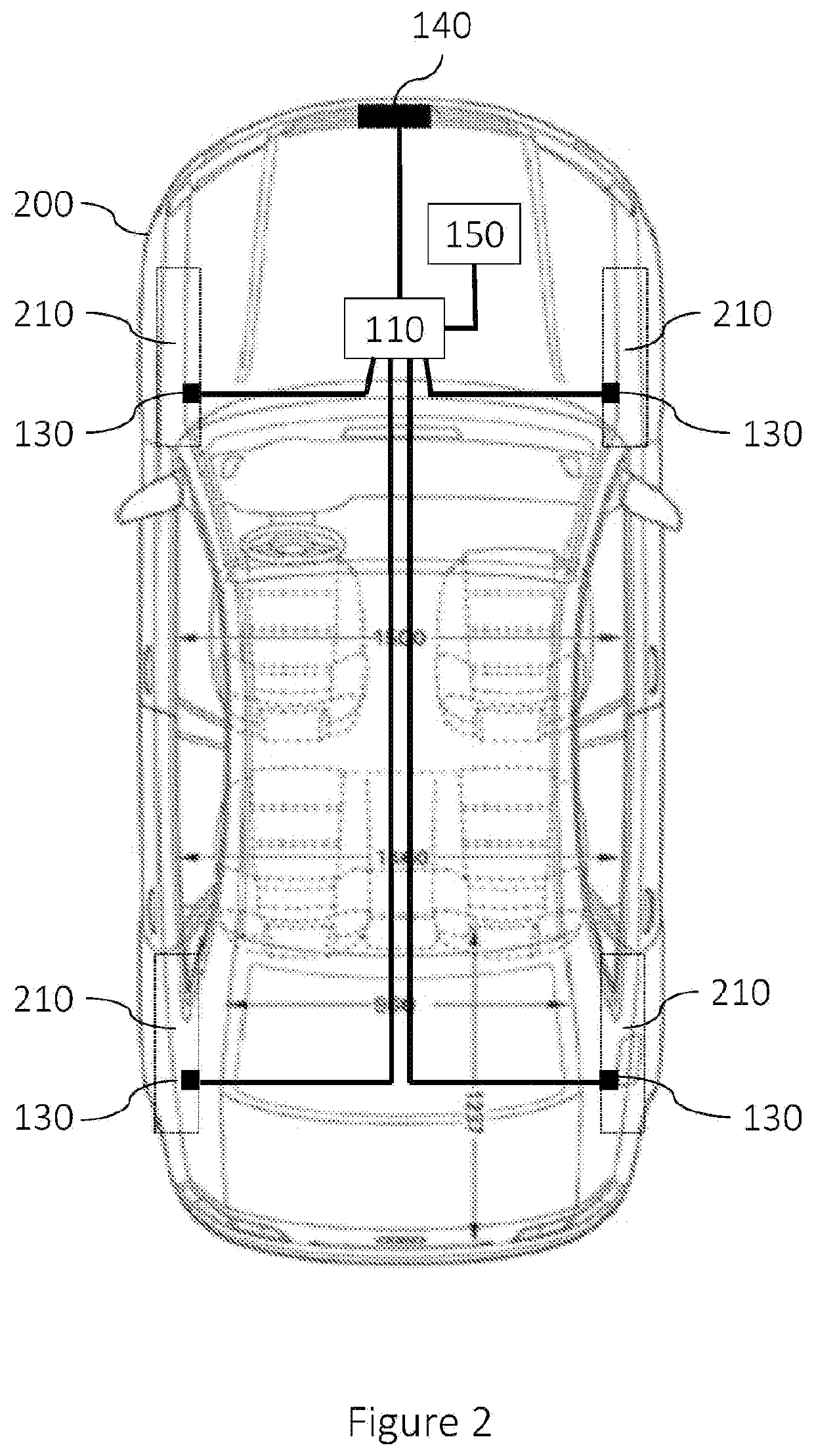

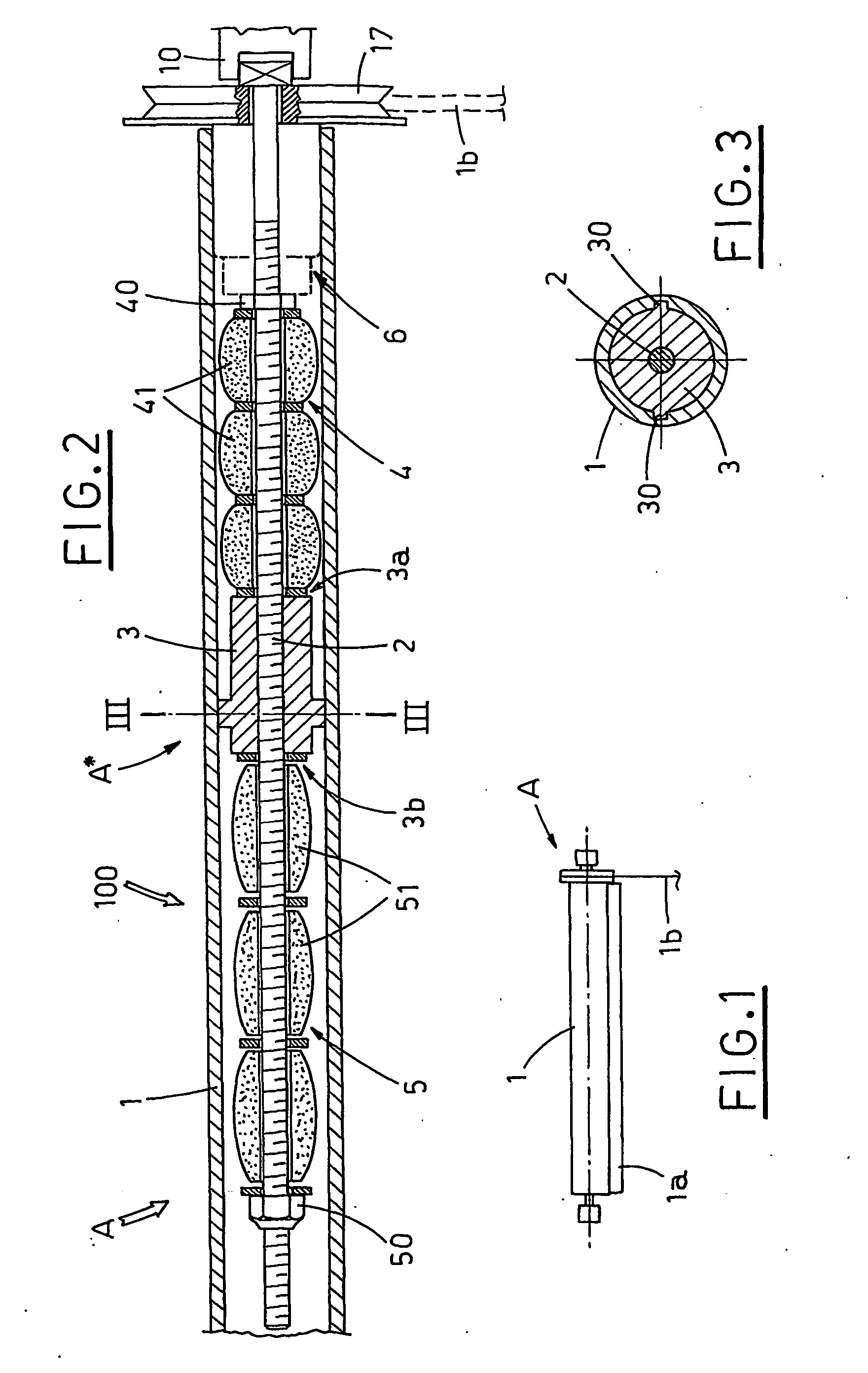

Track and bogie for suspended vehicles

ActiveUS8807043B2Preventing any significant slippage of the drive wheelsMinimize rolling resistanceMonorailsRailway tracksBogieSUSPENDING VEHICLE

The present invention includes a track (1, 101) of a track system with straight, transition, curved, and switch track sections. The invention further comprises bogies (40) for vehicle cabins suspended under the track. Track sections of the track have an upper rail (1) and one or two lower rails (101, 201). Further, a bogie (40) has fore and aft sets of upper guide and switch wheels (151, 251, 154, 254), and one set of lower guide and switch wheels (152, 153, 252, 253, 156, 157, 256, 257). The bogies (40) also have one left and / or one right load bearing wheel (150, 250) and one drive wheel facing upwards and engaging a downwards directed drive wheel running surface (15) of the upper rail. Each set of lower guide wheels consist of left and right wheel pairs (152, 153, 252, 253) so that transition sections can be passed without moving any parts of the bogie (40). Switch wheels (154, 254, 156, 157, 256, 257) are separated from guide wheels so that they can be positioned according to the preferred direction of travel well before reaching a switch.

Owner:SUPRAWAYS

Rotating cushion for fire truck

The invention provides a rotating cushion for a fire truck, belongs to the technical field of machinery, and solves the problem that a conventional cushion can disturb a fireman to get off the fire truck. The rotating cushion for the fire truck comprises a weight plate and a connecting plate located on the upper side of the weight plate, wherein the connecting plate and the weight plate are in the shape of a circular plate and are coaxial; a protruding rotating shaft is arranged at the central position of the lower end surface of the connecting plate, and the rotating shaft and the weight plate are axially fixed; a friction mechanism for generating frictional resistance between the weight plate and the connecting plate is arranged between the weight plate and the connecting plate; a housing with a closed chamber is fixedly connected to the upper end surface of the connecting plate, and is manufactured from flexible materials; the chamber is stuffed with sponge; the housing adopts the shape of the circular plate in a stuffed state; a limiting column is fixedly connected to the lower end surface of the connecting plate; and two limiting pieces which can separately prop against the limiting column are separately arranged on the weight plate when the connecting plate rotates relative to the weight plate, and the two limiting pieces are separately located on two sides of the limiting column. The rotating cushion for the fire truck disclosed by the invention has the advantage of shortening the time for getting off.

Owner:TIANJIN DEBANG FIRE FIGHTING EQUIP

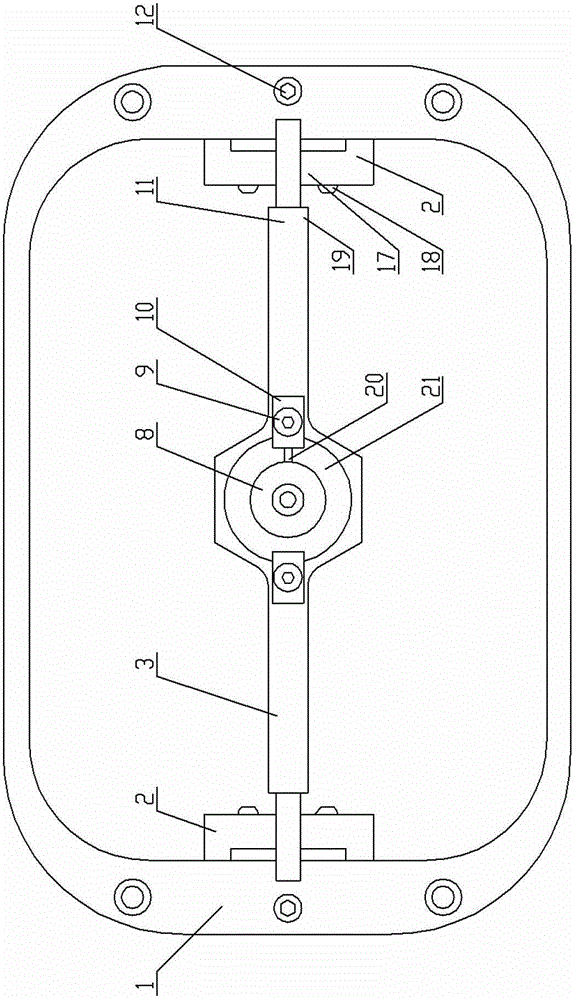

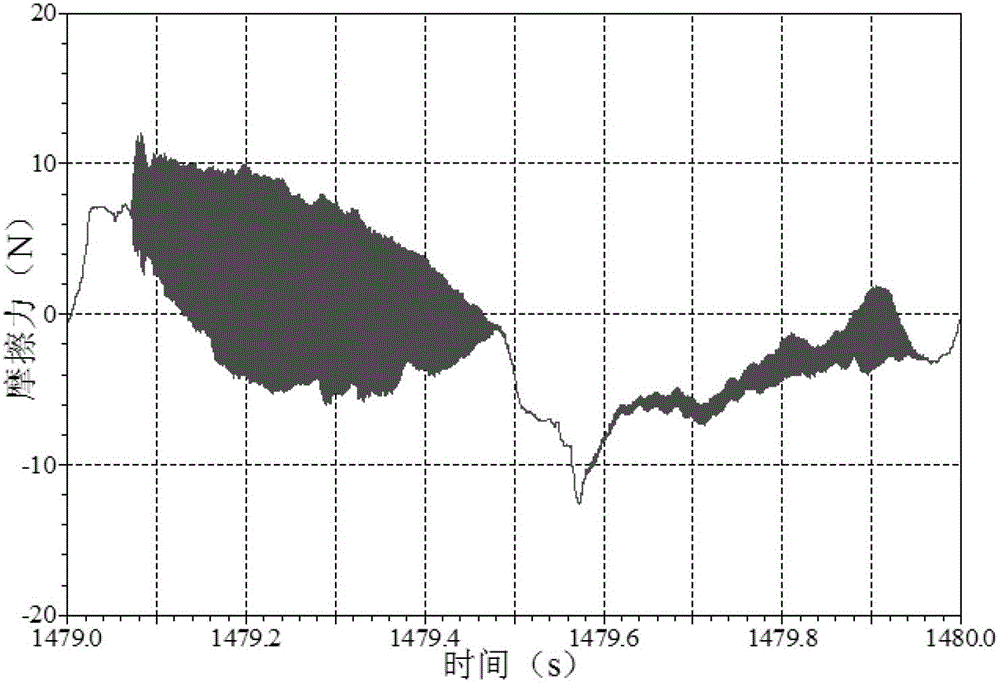

Method for testing and analyzing frictional noise and test device for method

InactiveCN102680083BSimple designEasy to useAcceleration measurement using interia forcesSubsonic/sonic/ultrasonic wave measurementReal time analysisVibration acceleration

The invention discloses a method for testing and analyzing frictional noise and a test device for the method. The method comprises that: a lower fixture clamping a lower friction part is fixed onto a reciprocating device; an upper fixture clamping an upper friction part penetrates through a horizontal support to contact with the bottom of a strain force sensor; a three-dimensional acceleration sensor is mounted on the upper fixture; two ends of the horizontal support are fixed onto support bases by piezoelectric force sensors; and the strain force sensor is fixed to the bottom of a two-dimensional moving table. A sensing end of an acoustic sensor is close to a contact interface of the upper friction part and the lower friction part, and the two-dimensional moving table is controlled so that the upper friction part and the lower friction part are controlled to do reciprocating friction motion, and the three sensors accurately, synchronously and dynamically acquire the frictional noise, vibration acceleration and frictional force and analyze the frictional noise, the vibration acceleration and the frictional force in real time. Therefore, mutual relation and influencing law of the frictional noise, the interface and characteristics of a system are accurately analyzed, a mechanism of production of the frictional noise is disclosed, and a more accurate and reliable test basis is provided for realizing noise-reduction design for mechanical equipment, improving performance of the mechanical equipment and prolonging the service life of the mechanical equipment.

Owner:SOUTHWEST JIAOTONG UNIV

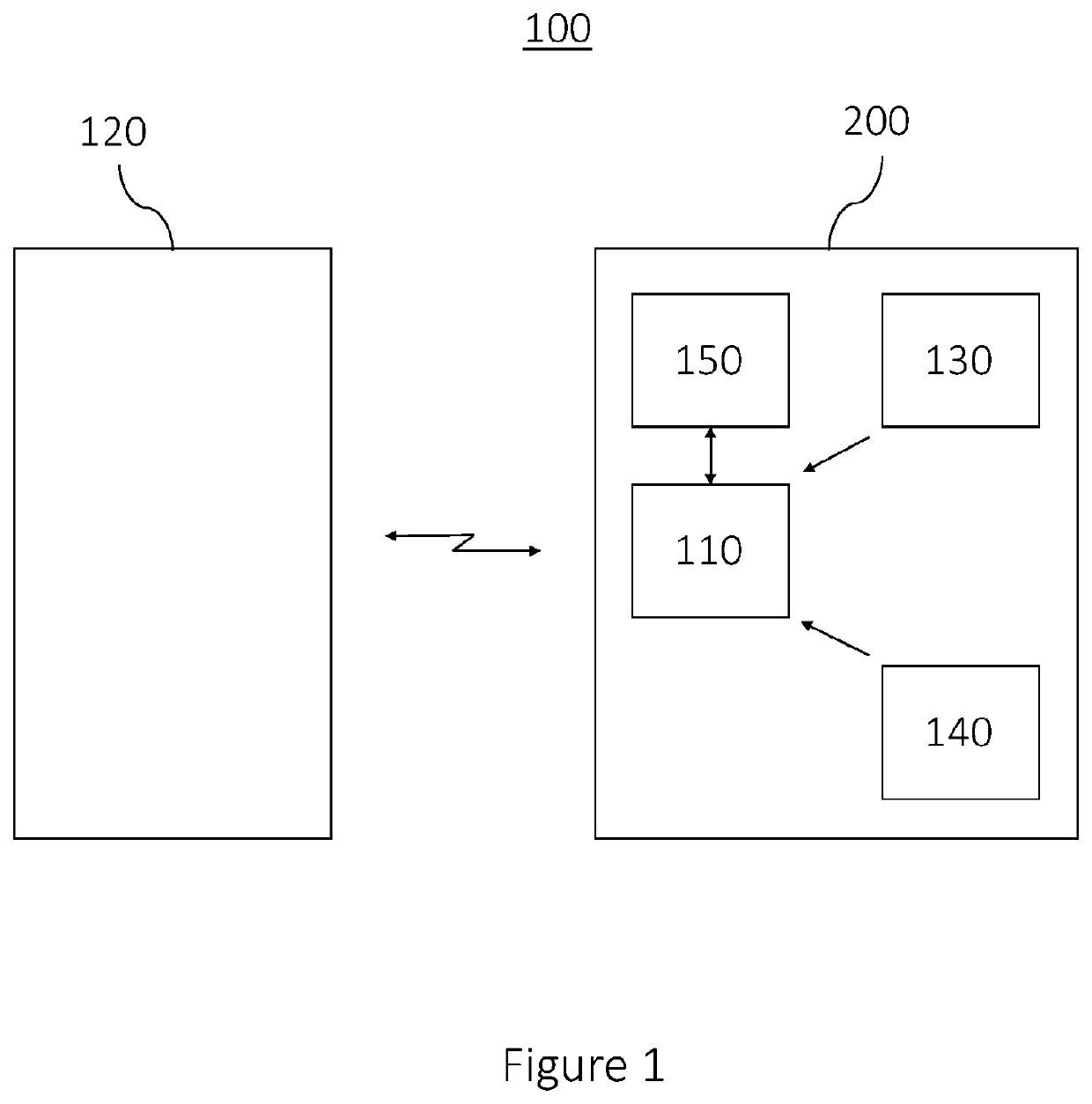

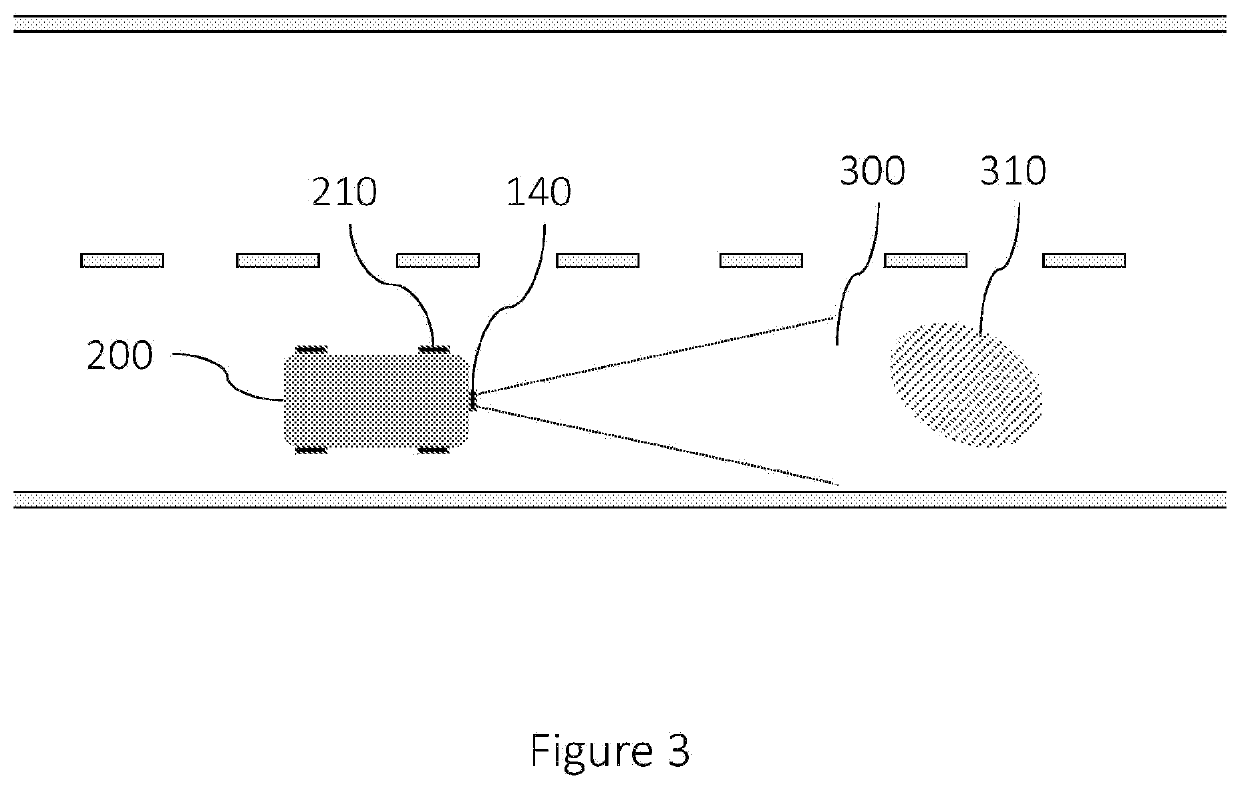

Friction estimation

ActiveUS20200231163A1OptimizationImprove accuracyExternal condition input parametersBraking systemsRoad surfaceControl theory

A system for estimating the friction between a road surface and a tire of a vehicle includes at least one first sensor and at least one vehicle processing device containing a friction estimation algorithm which is arranged to estimate the friction between the road surface and the tire of the vehicle based on friction related measurements is provided. The vehicle processing device is arranged to: receive an estimate of the expected friction between the road surface and the tire of the vehicle from a central processing device, from a storage device in the vehicle, or from at least one second sensor in the vehicle; adapt the friction estimation algorithm based on said received estimate of the expected friction; receive at least one friction related measurement from the at least one first sensor in the vehicle; and use the adapted friction estimation algorithm to perform an estimation of the friction between the road surface and the tire of the vehicle based on the at least one friction related measurement.

Owner:NIRA DYNAMICS AB

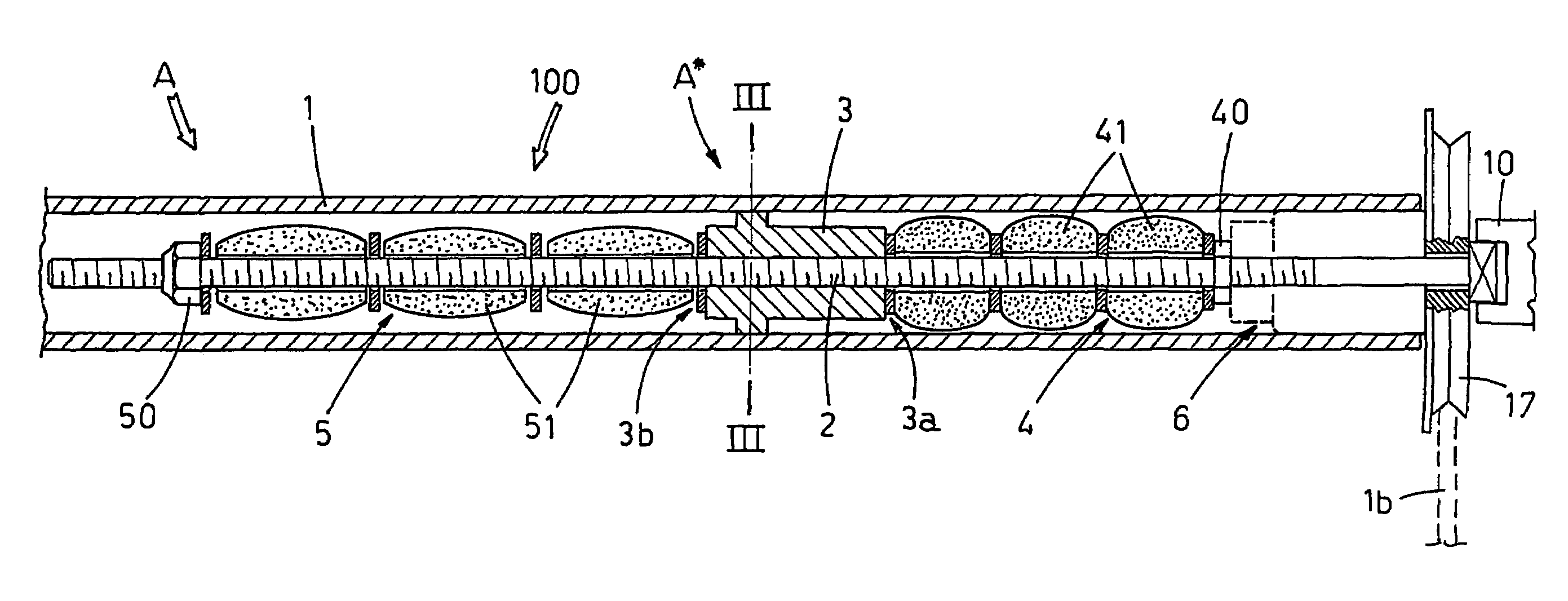

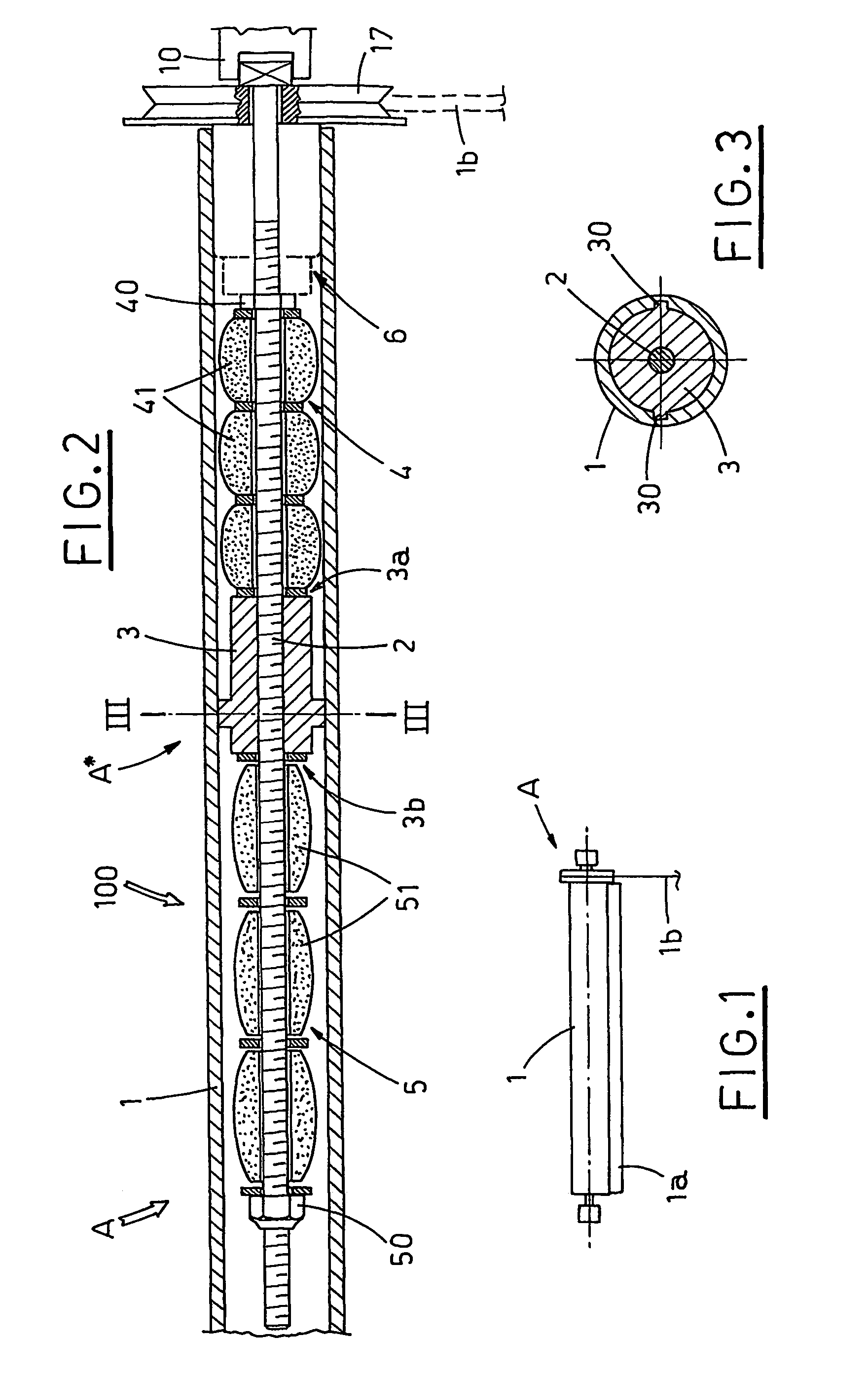

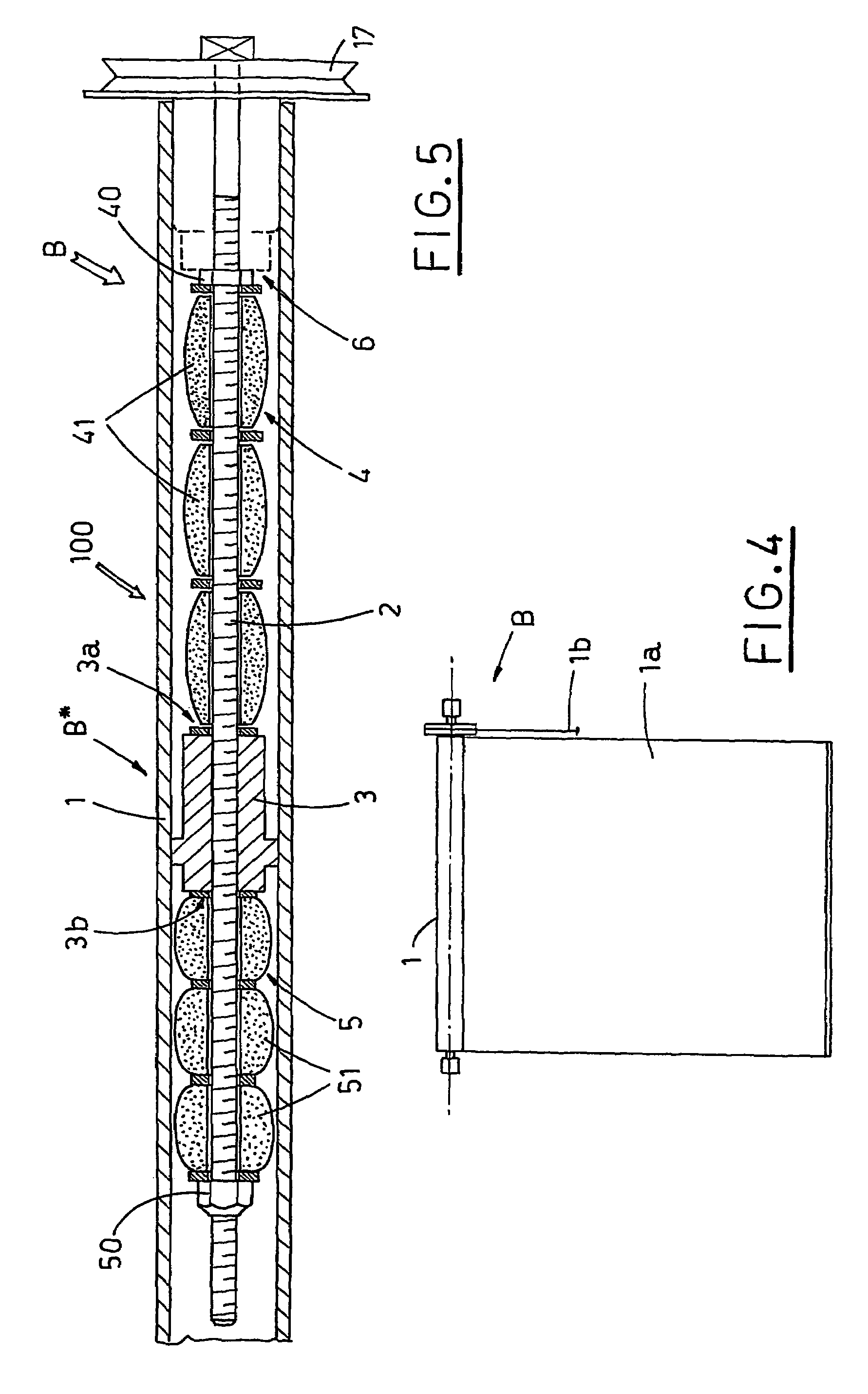

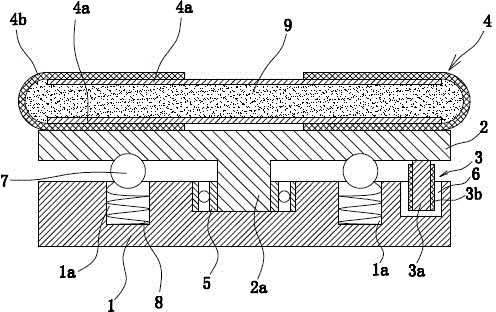

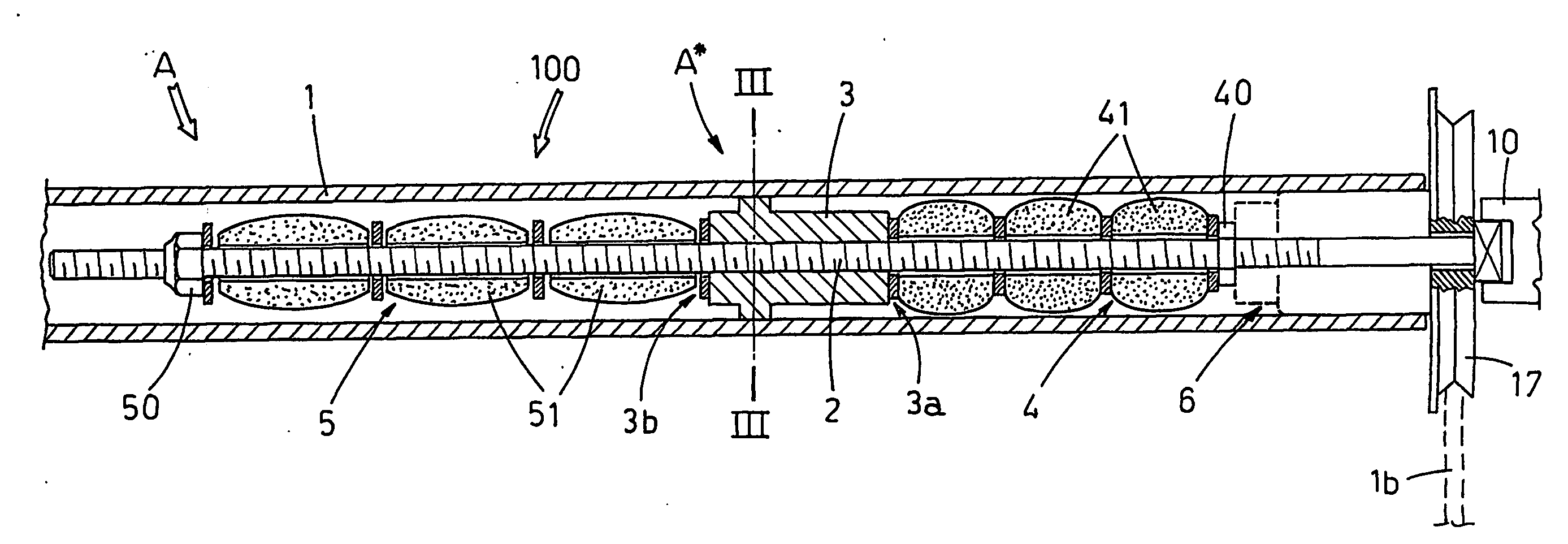

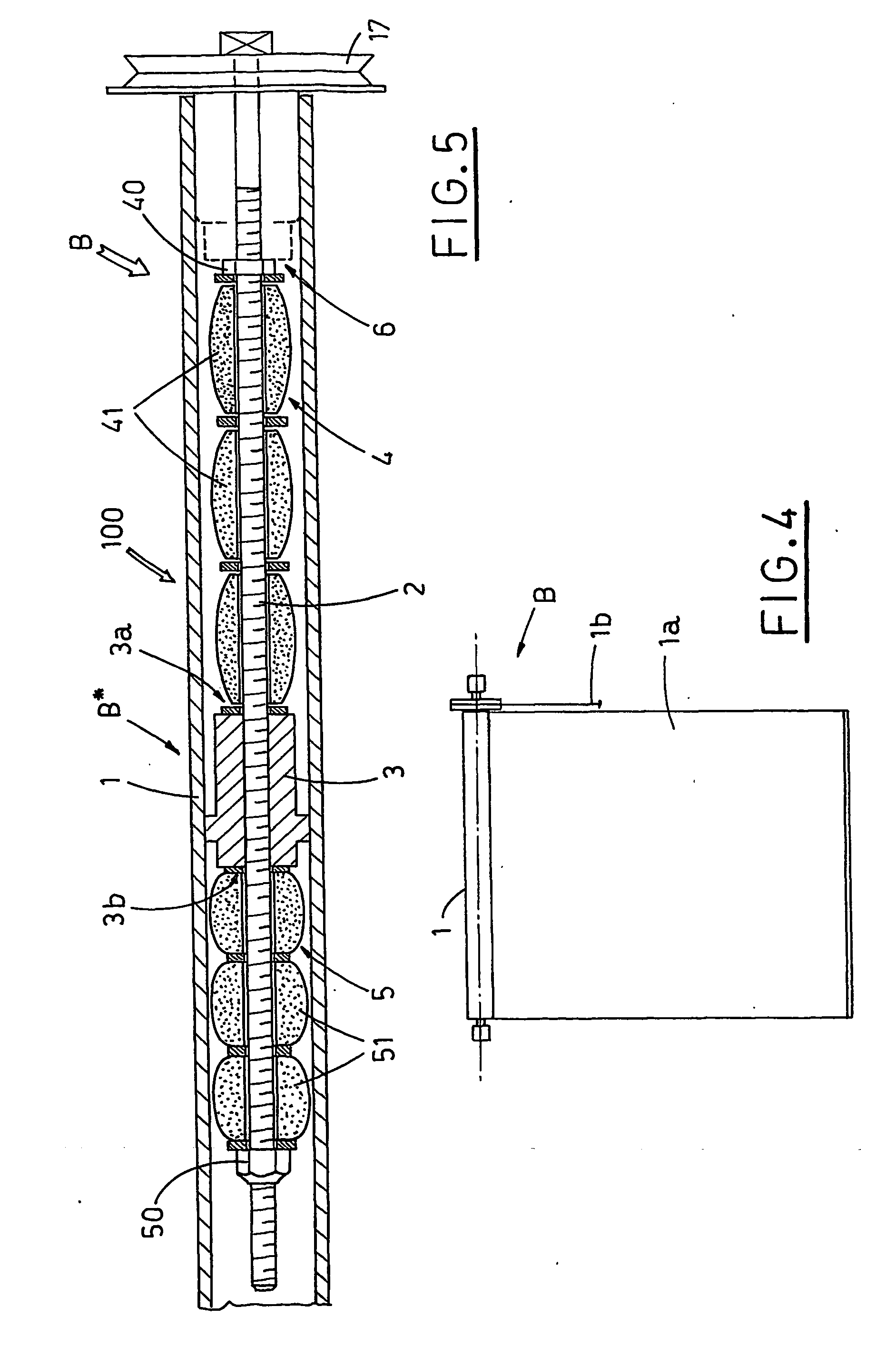

Friction device for rolling up curtains and the like

ActiveUS20060219371A1Improve stabilityImprove balanceDoor/window protective devicesPower-operated mechanismFriction effectCoupling

A friction device for rolling up curtains and the like includes a tubular roller (1), on which a curtain (1a) is wound. The roller (1) is rotatably carried by a support (10) and a threaded stem (2) is situated axially inside the roller (1) and carries, mounted thereon by a screw coupling, an operative body (3), likewise situated inside the roller (1). The operative body (3) translates axially with respect to the threaded stem (2) during motion of the curtain (1a) from a rolled up configuration (A) to a unrolled configuration (B). Elastic blocks (41, 51) push on the operating body (3) to produce a friction effect on the operating body and transmitted to roller (1) during curtain (1a) transition between the unrolled and rolled up configurations, thus allowing operation of the curtain in a substantially balanced way during rolling up and / or unrolling. Stop nuts (40, 50) are fastened to the threaded stem (2) for compressing the elastic blocks against surfaces of the operating body (3).

Owner:SILENT GLISS ITAL SRL

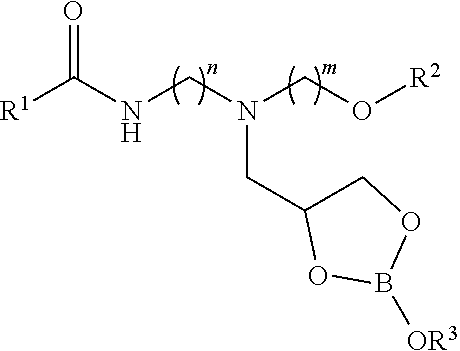

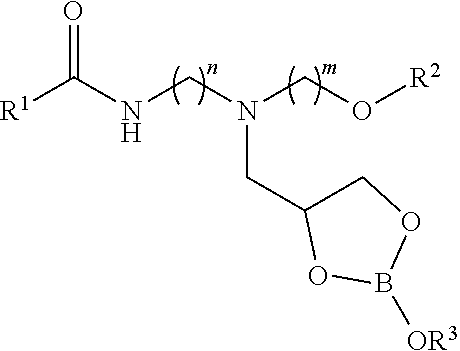

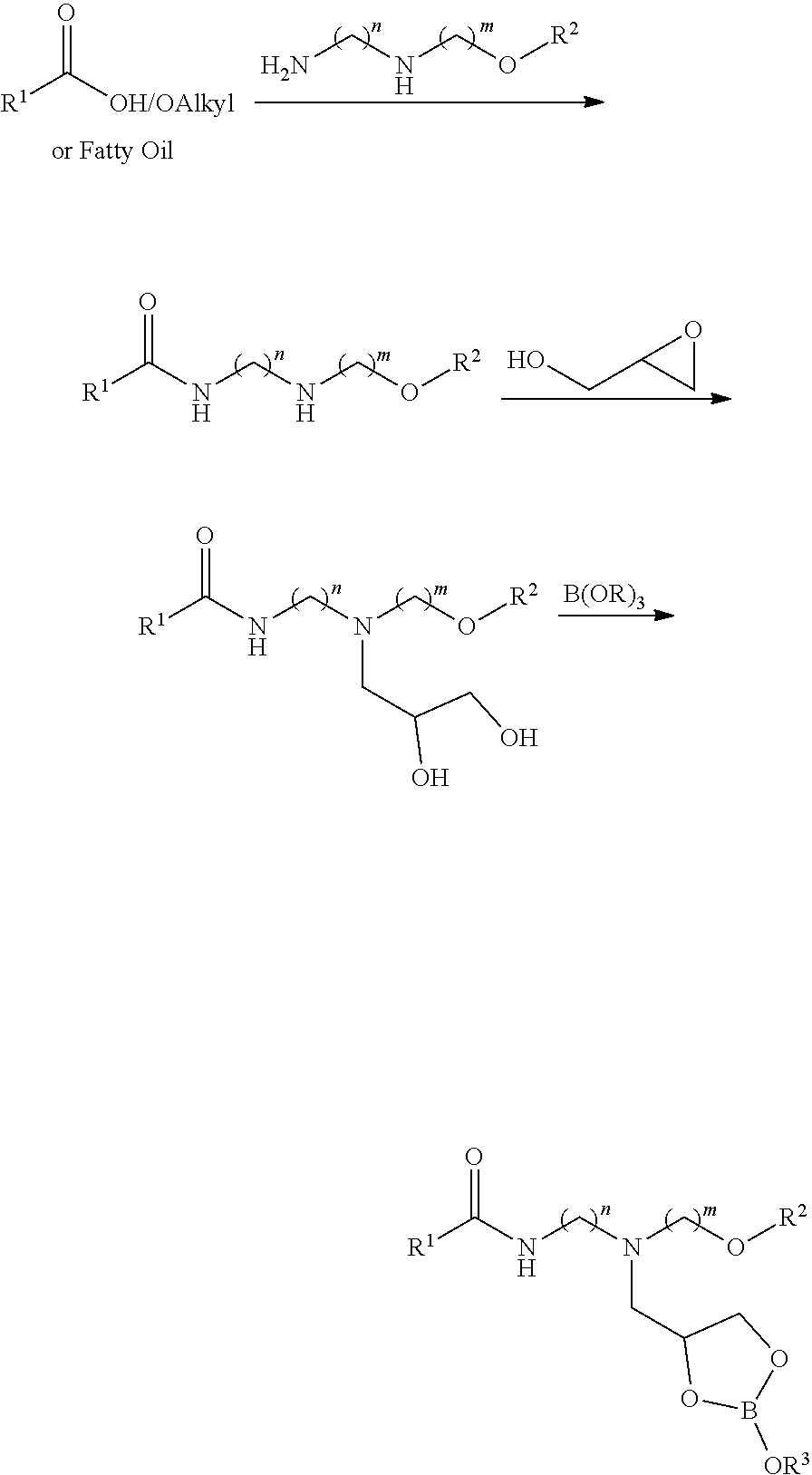

Less corrosive organoboron compounds as lubricant additives

ActiveUS11046717B2Reduce severityImprove performanceGroup 3/13 element organic compoundsAdditivesBoronic acidOrganoboron compounds

Owner:VANDERBILT CHEM LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com