Inside single-beam sealed prestressed group-anchor system and construction method thereof

A prestressed and prestressed tendon technology, applied in the processing of building materials, structural elements, building components, etc., can solve the problems of increasing the diameter of the reserved holes in the structure, filling a large amount of anti-corrosion materials, and being inconvenient for installation and construction. Easy to change cables or temporary anchoring, high construction efficiency, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A single-bundle sealed prestressed group anchor system in the body:

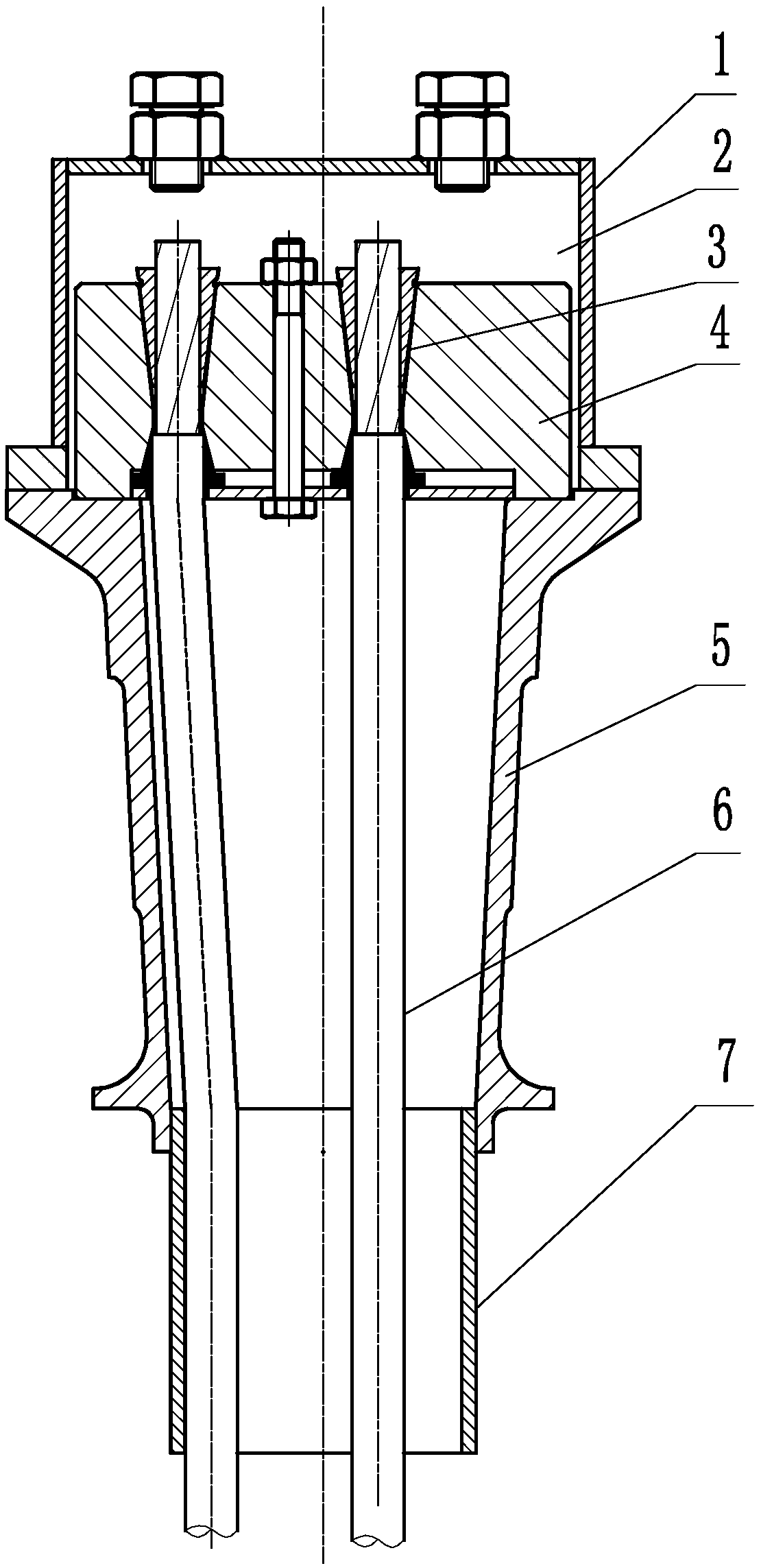

[0060] Such as figure 1 As shown, the single-bundle sealed prestressed group anchor system in the body includes a protective cover assembly 1, a working clip 3, an anchor plate, an anchor backing plate 5, m unbonded prestressed tendons 6, and a pre-embedded tunnel 7;

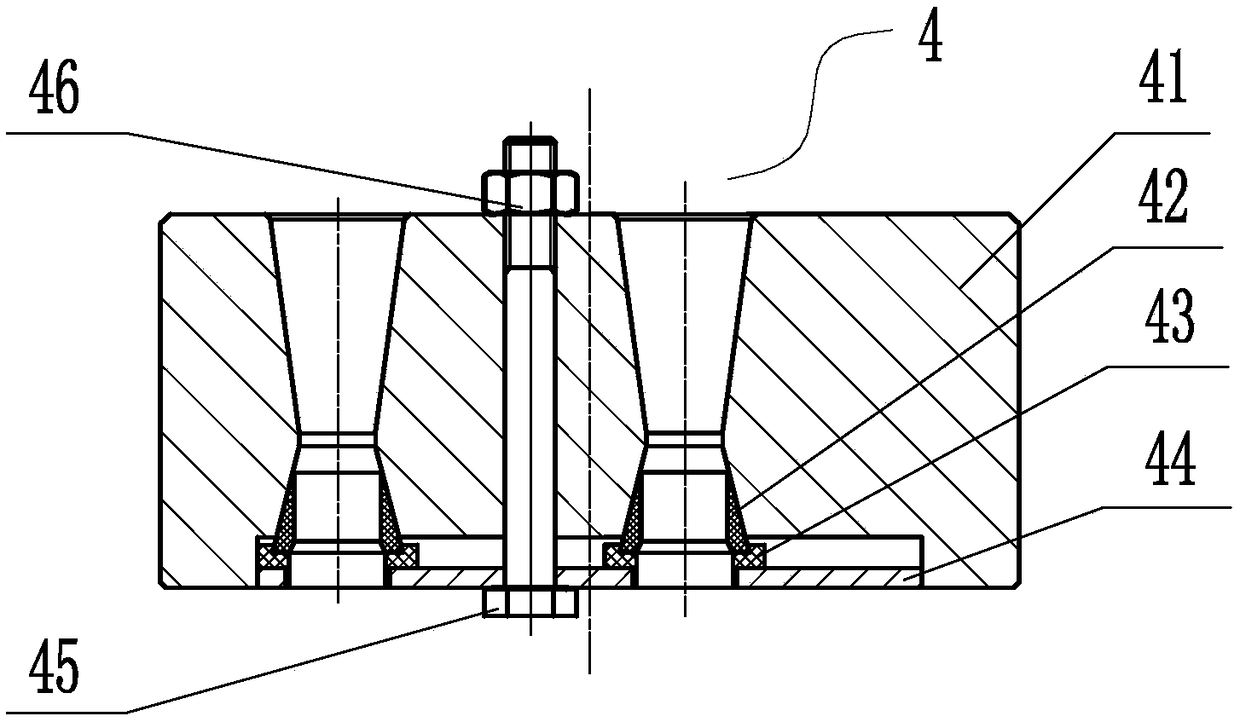

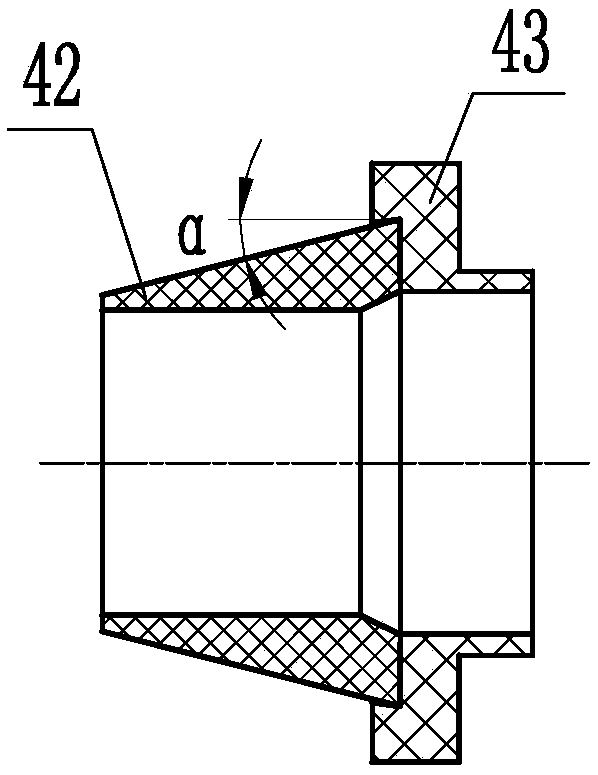

[0061] The unbonded prestressed tendon 6 is a single-bundle sealed prestressed tendon, and the anchor plate is a sealed anchor plate assembly 4, such as figure 2 As shown, the sealing anchor plate assembly 4 includes a working anchor plate 41, a rubber taper sleeve 42, a plastic limit sleeve 43 and a pressing plate 44. One end of the working anchor plate 41 is provided with a tapered hole I 411 for installing the clip. The working anchor The other end of the plate 41 has a groove 414, the pressing plate 44 is located in the groove 414, and the tail of the straight hole 412 in the working anchor plate has a tapered hole II 413 (see ...

Embodiment 2

[0067] A construction method of a single-bundle sealed prestressed group anchor system in the body, which comprises the following steps:

[0068] A. Preparations before construction: Prefabricate the components of the sealing anchor plate assembly 4 in the factory, including the working anchor plate 41, the rubber cone sleeve 42, the plastic limit sleeve 43 and the compression plate 44 (see Figure 3-Figure 6 );

[0069] B. After positioning and installing the anchor plate 5 and the pre-embedded tunnel 7 (corrugated pipe or extraction pipe), pour concrete;

[0070] C. After the concrete reaches the required strength, pass the prestressed tendon through the tunnel, and peel off the PE sheath at the end of the prestressed tendon;

[0071] D. Install sealing anchor plate assembly 4:

[0072] Install the sealing anchor plate assembly 4 on the anchor pad 5, and raise it to a certain height so as to pass through the bundle;

[0073] E. Wearing beams:

[0074] Pass each prestress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com