Vertical high-rise escape device and usage method thereof

An escape device and vertical technology, applied in life-saving equipment, building rescue and other directions, can solve the problems of not holding the escape rope tightly, high danger, time-consuming and labor-intensive escapers, etc., to achieve easy control of speed and high safety. , the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

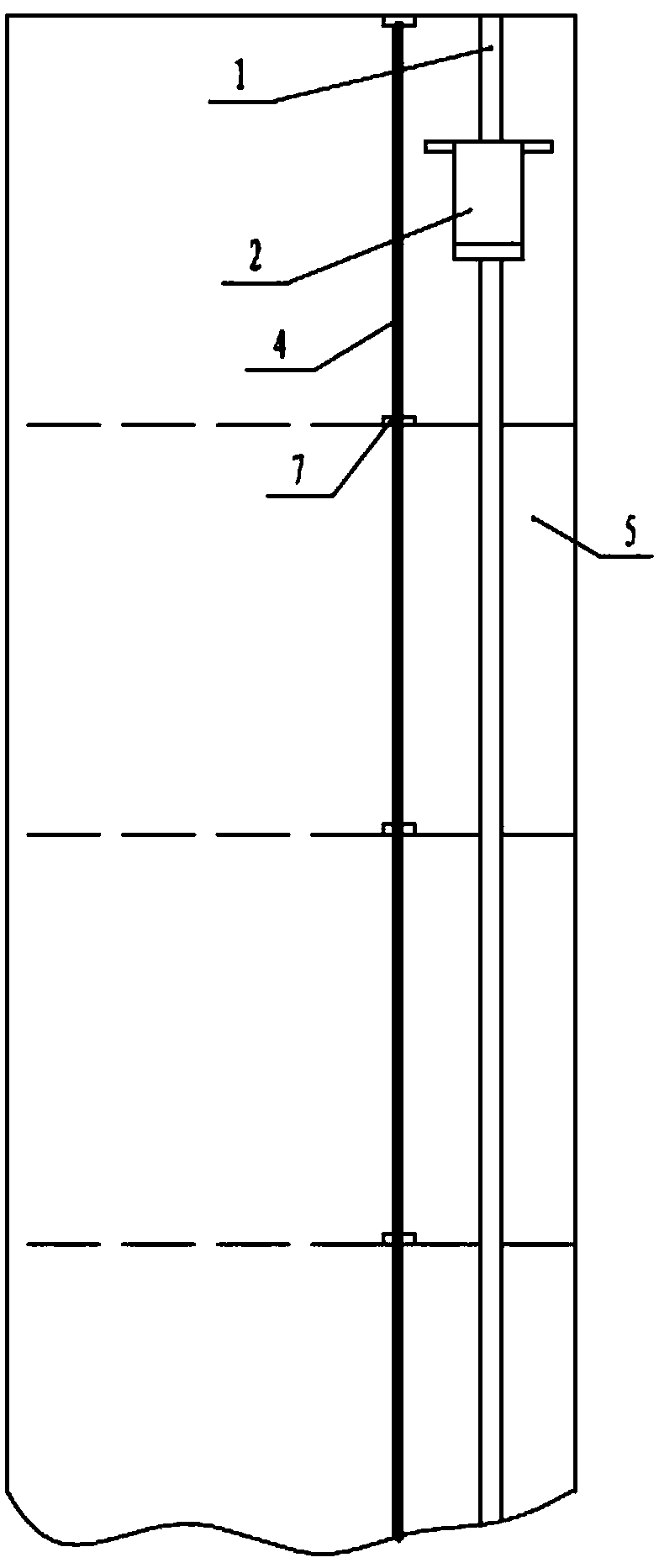

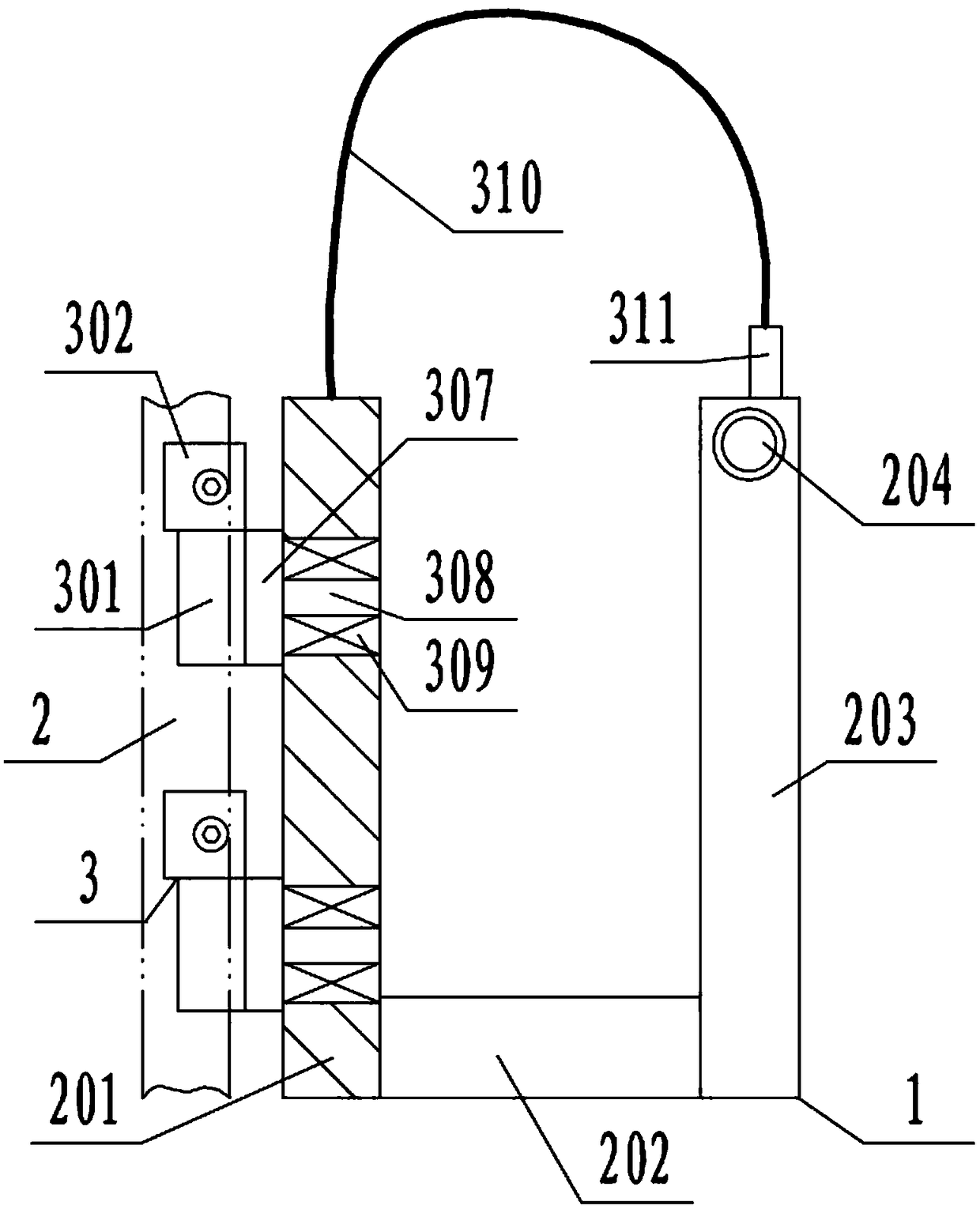

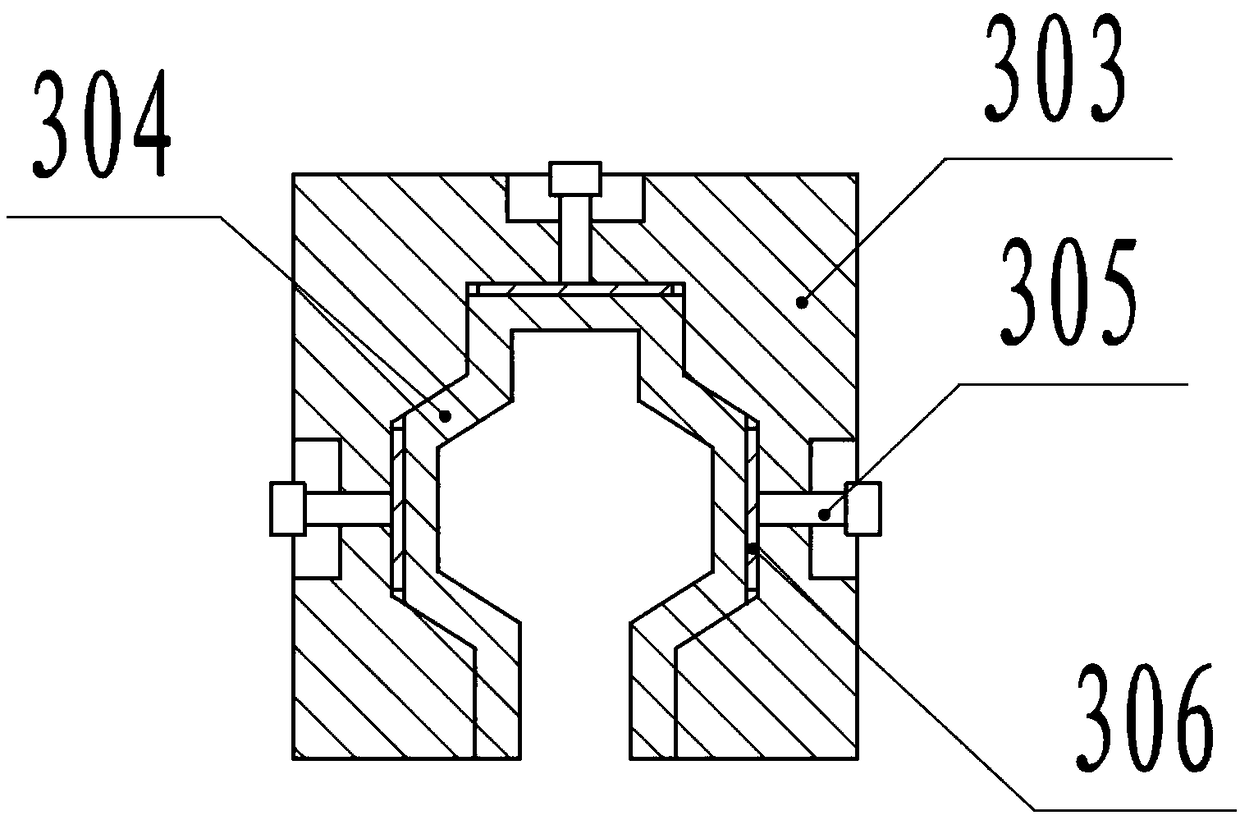

[0040] Embodiment 1: as Figure 1-Figure 4 As shown, a vertical high-rise escape device includes a vertical linear track 1 and a track trolley 2 installed outside the high-rise wall 5, the track trolley 2 is tightly connected to the linear track 1 through a friction slider 3 and the track trolley 2 When the load-bearing gravity is greater than the frictional force, it slides down, and it also includes a stay rope 4, which is installed next to the vertical linear track 1, and a limit sleeve 7 is set outside the wall 5 facing each floor to prevent the stay rope Suspended, unreliable to hold.

[0041] Preferably, the above-mentioned rail trolley 2 includes a slide plate 201, a cushion 202 and a backrest 203. Two friction sliders 3 are installed on the back side of the slide plate 201, and the bottom of the front side is vertically connected to the cushion 202. Skateboard 201 forms U-shaped structure, and linear track 1 is fixedly connected on the high-rise building wall 5 by I-s...

Embodiment 2

[0046] Embodiment 2: a method for using a vertical high-rise escape device, the method includes the following steps:

[0047] (1) Install the linear guide block and friction pair of the escape device on the linear track in sequence;

[0048] (2) Fasten the friction pair on the linear guide block and adjust the friction force;

[0049] (3) When in use, the human body sits on the cushion and faces the wall, with one hand leaning on the armrest, and the other hand pulling the drawstring;

[0050] (4) Give the escape device an initial force by external force or pulling the pull rope to obtain an initial speed;

[0051] (5) Under the action of friction, the human body descends to the ground along the straight track to realize escape.

[0052] The movement process of the escape device at the start and end of each floor satisfies:

[0053]

[0054] Among them, m is the total mass of the escape device and the person;

[0055] v 1 is the initial velocity;

[0056] h is the hal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com