Rotating cushion for fire truck

A technology for fire trucks and seat cushions, applied in thigh cushions, fire rescue and other directions, can solve the problems of fire extinguishing effects, increased consumption time, fixed seat cushions, etc., to reduce shaking, shorten consumption time, and improve comfort. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

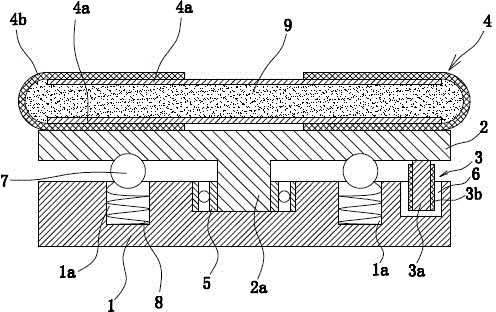

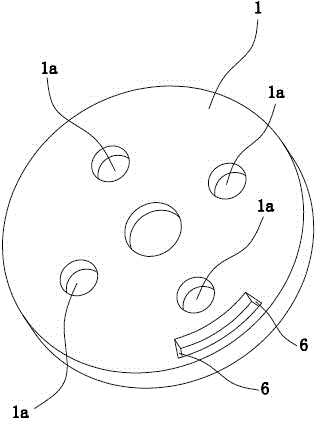

[0027] Such as figure 1 As shown, the rotating seat cushion used by this fire truck is made up of counterweight plate 1, connecting plate 2, limit post 3, housing 4 and so on. Wherein, both the counterweight plate 1 and the connecting plate 2 are disc-shaped and coaxial. In actual use, the counterweight plate 1 is placed on the seat to position the entire swivel cushion, and at this time, the connecting plate 2 is located on the upper side of the counterweight plate 1 .

[0028] The center of the lower end surface of the connecting plate 2 has a cylindrically protruding rotating shaft 2 a, and the rotating shaft 2 a is axially fixed with the counterweight plate 1 . Specifically, a slot is provided on the upper end surface of the weight plate 1 , and a bearing 5 is arranged in the slot, and the outer ring of the bearing 5 and the weight plate 1 are fixed together by welding. The rotating shaft 2a is in interference fit with the inner ring of the bearing 5, so as to achieve th...

Embodiment 2

[0036] The structure and principle of the second embodiment are basically the same as those of the first embodiment, except that the friction mechanism is a friction disc sleeved on the rotating shaft 2a, one end of the friction disc is fixedly connected with the weight plate 1, And the other end of the friction disc is against the connecting plate 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com