Fishing boat stern shaft braking device

A brake device and stern shaft technology, applied in the direction of brake parts, brake types, drum brakes, etc., can solve the problems of long inertia braking time, large damage to reverse braking transmission components, and short braking time. Achieve the effect of less damage to parts, reliable stop and high braking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

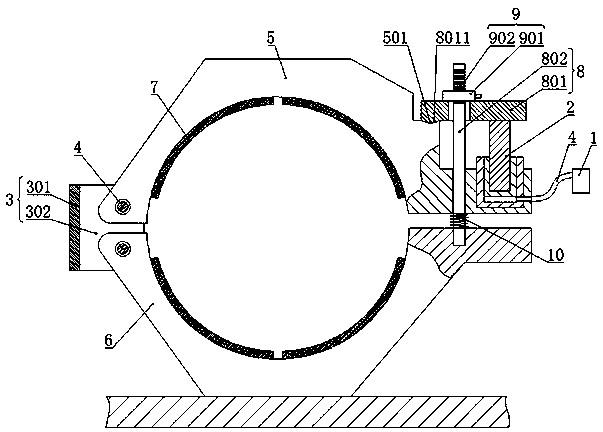

[0018] exist figure 1 Among them, a fishing boat stern shaft braking device, which includes a hydraulic pump station 1, a hydraulic cylinder 2 and a mounting plate assembly 3. Wherein, the hydraulic cylinder 2 communicates with the hydraulic pump station 1 through a hydraulic pipe 11 in a conventional connection manner.

[0019] Such as figure 1 As shown, a fishing boat stern shaft braking device also includes a semi-annular upper hoop 5 and a semi-annular lower hoop 6, the upper hoop 5 and the lower hoop 6 can form an encircling shape. When in use, the upper hoop body 5 and the lower hoop body 6 surround the stern shaft of the fishing boat to achieve braking on the stern shaft of the fishing boat.

[0020] In order to improve the friction force of the upper hoop body 5 and the lower hoop body 6 when braking the stern shaft of the fishing boat, as figure 1 As shown, friction plates 7 are respectively provided on the opposite surfaces of the upper hoop body 5 and the lower h...

Embodiment 2

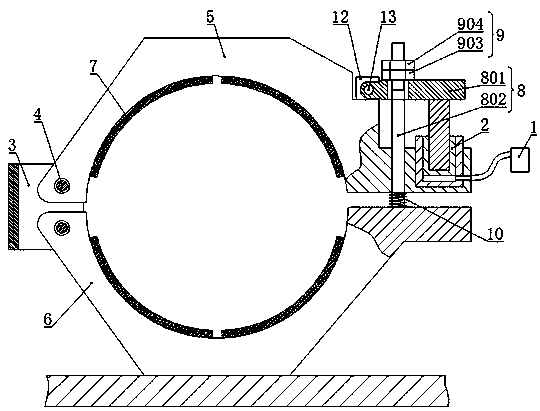

[0029] figure 2 The structure of another embodiment of the present invention is given.

[0030] exist figure 2 Among them, a braking device for the stern shaft of a fishing boat, which is the same as that of Embodiment 1, includes a hydraulic pump station 1, a hydraulic cylinder 2, a mounting plate assembly 3, a semi-circular upper hoop body 5 and a semi-circular The lower hoop body 6, the connecting ends of the upper hoop body 5 and the lower hoop body 6 are respectively connected to the mounting plate assembly 3 through the connecting piece 4; friction plate 7; an actuator 8 is arranged between the locking ends of the upper hoop body 5 and the lower hoop body 6; the cylinder body of the hydraulic cylinder 2 is fixed on the locking end of the upper hoop body 5, and the piston rod of the hydraulic cylinder 2 The upper hoop body 5 and the lower hoop body 6 are tightened or loosened by the actuator 8 . Wherein, its actuator 8 also includes a drive plate 801 and a pull rod 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com