Air cylinder friction force testing device and method

A testing device and friction technology, applied in measuring devices, force/torque/work measuring instruments, instruments, etc., can solve the problems affecting the accuracy of friction force, the influence of friction force, the inability of the precision pressure reducing valve to respond in time, etc., and achieve good results. Universal, high-precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

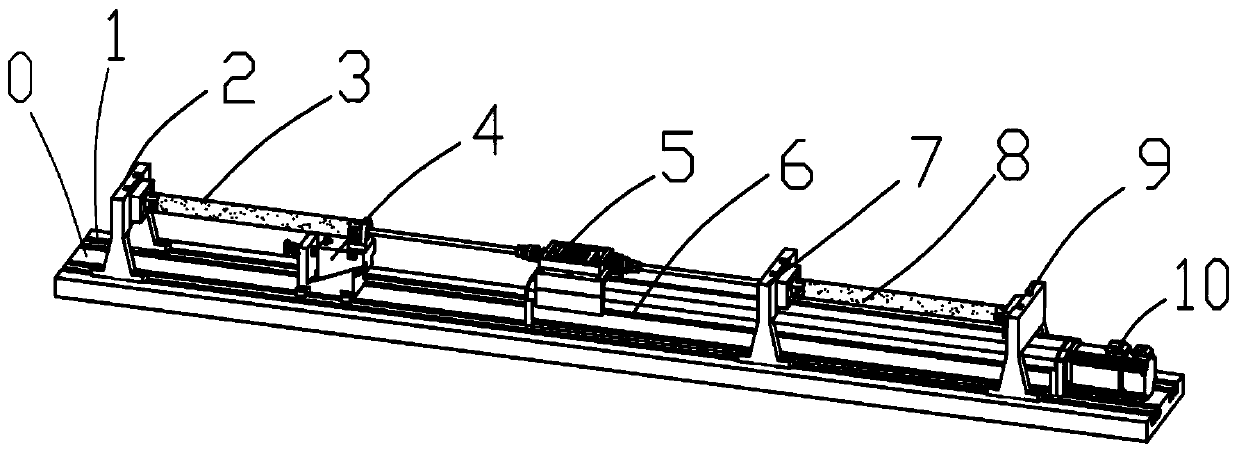

[0049] like figure 1 As shown, the cylinder friction detection device of the present invention includes a mounting platform, a motion transmission component, a connecting assembly 5, a measured part, a supporting component and a cylinder pressure control system. Both the motion transmission part and the supporting part are installed on the installation platform.

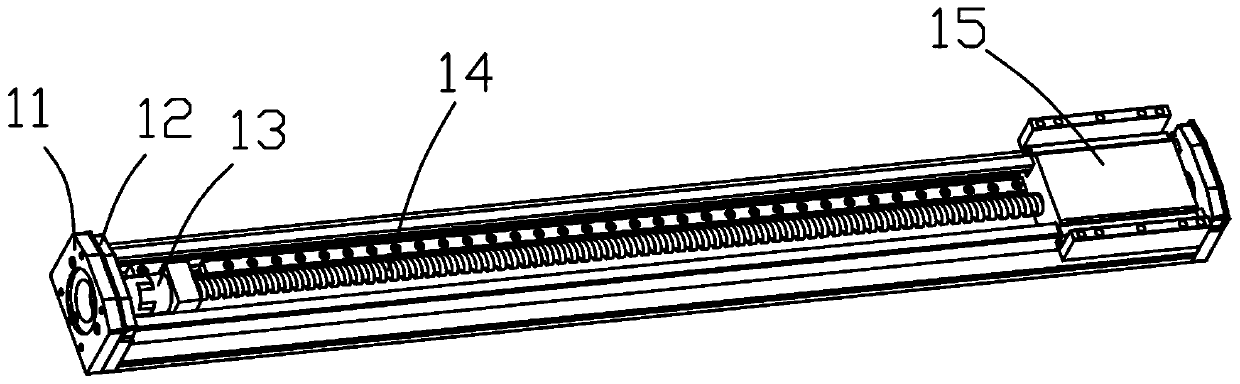

[0050] like figure 2 As shown, the motion transmission components include a servo motor 10 and a ball screw mechanism 6 . The end cap 12 of the ball screw mechanism 6 is provided with four threaded holes; the flange 11 is provided with four countersunk holes and four threaded holes, and the hexagon socket bolts pass through the countersunk holes on the flange 11 The hole is screwed and fastened to the end co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com