Lifting rope angle measurer for crane

A technology of angle measuring device and suspending rope, applied in measuring device, safety device, electric device, etc., can solve the problems of affecting the accuracy of swing angle measurement, affecting the life of spring arm, etc., and achieve automation improvement, high reliability and high precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

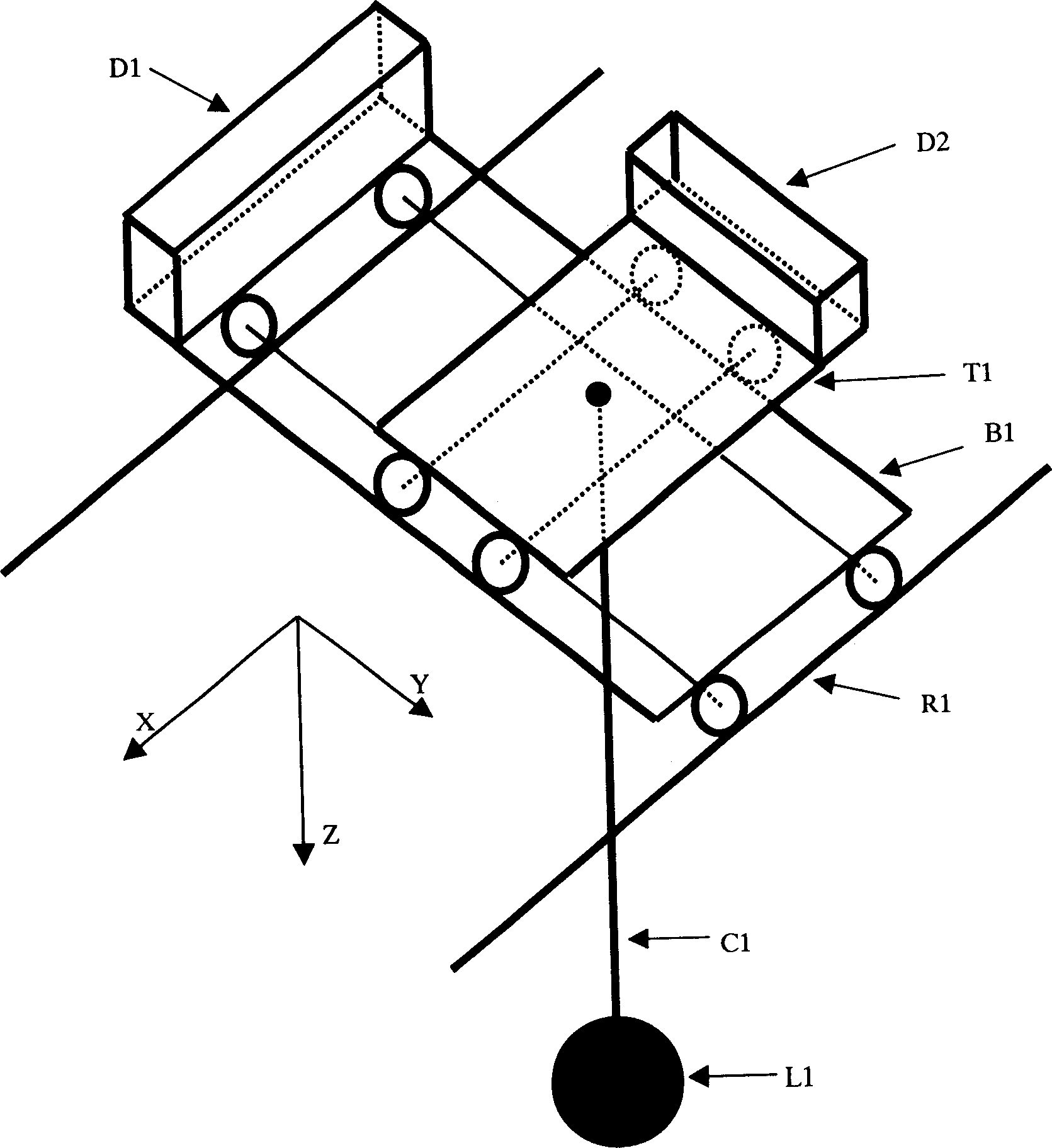

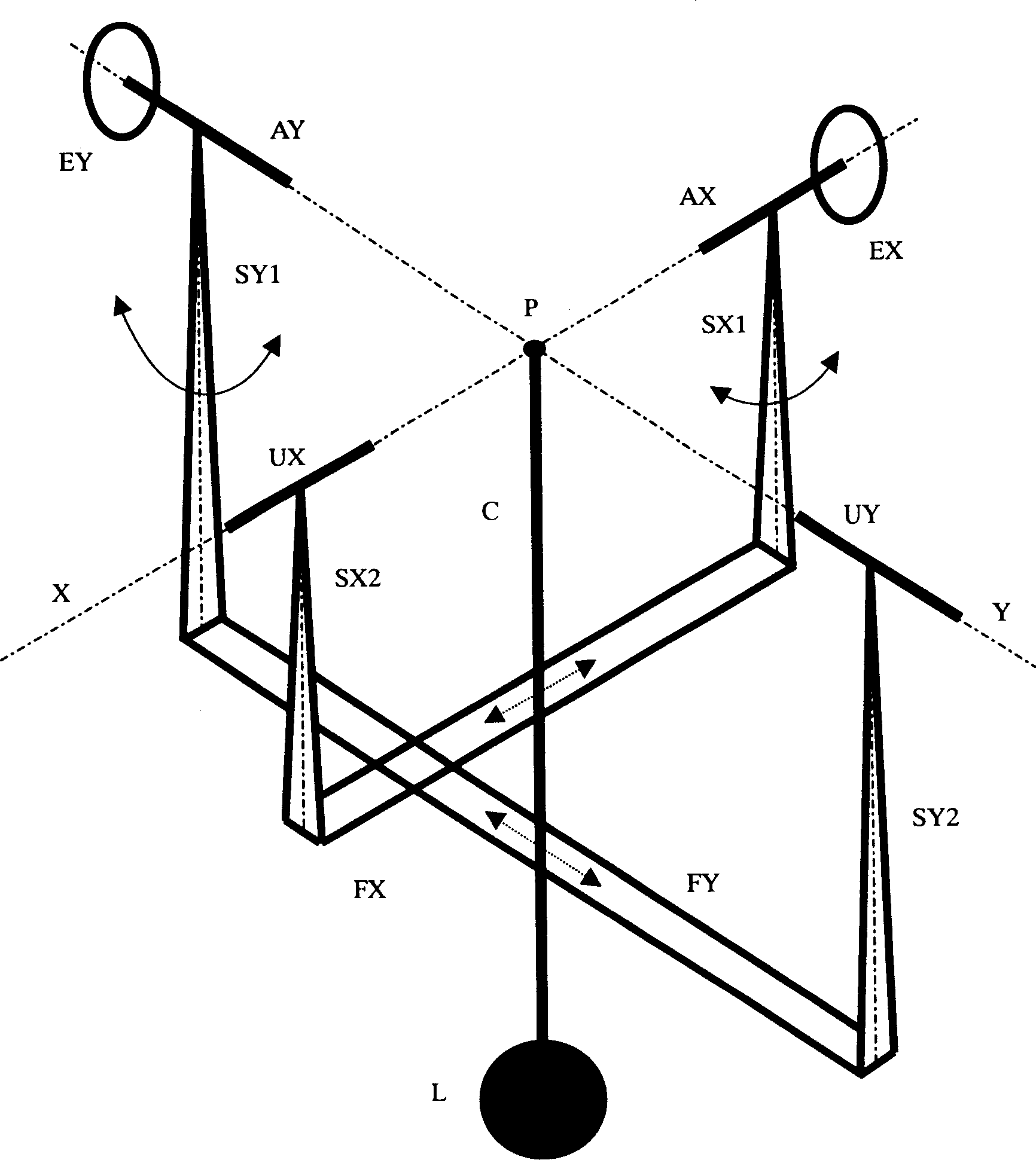

[0031] This measuring device passes Figure 4 The block diagram shown constitutes the angle measurement system and forms an important part of the crane's control system. In the example, we have customized a model crane with a height of 1.20 meters, a track length of 2.00 meters, a beam length of 1.00 meters, and a total beam weight of 20.00 kg. The size of the trolley is a square of 0.30m x 0.30m and the weight is 10.00kg. The diameter of the sling is 0.02 meters, the longest time is 0.80 meters, the shortest time is 0.4 meters, and the weight of the heavy object is 10.00 kg. This measuring device is installed on the lower part of the trolley. One of the U-frames is parallel to the track, which is 0.20 meters long and 0.30 meters high. The other U-shaped frame is parallel to the beam, its length is 0.20 meters and its height is 0.25 meters. The inner width of the U-shaped frame is 0.03 meters. In this way, the two frames do not touch each other in space, and the weight is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com