Tunnel vehicle-mounted folding type multifunctional work rack

A foldable and multi-functional technology, applied in tunnels, tunnel linings, shaft linings, etc., can solve the problem that the work bench cannot pass through the pre-grooving equipment passable space, the progress of entering and exiting the construction work surface is slow, and the utilization efficiency of the work bench is low. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

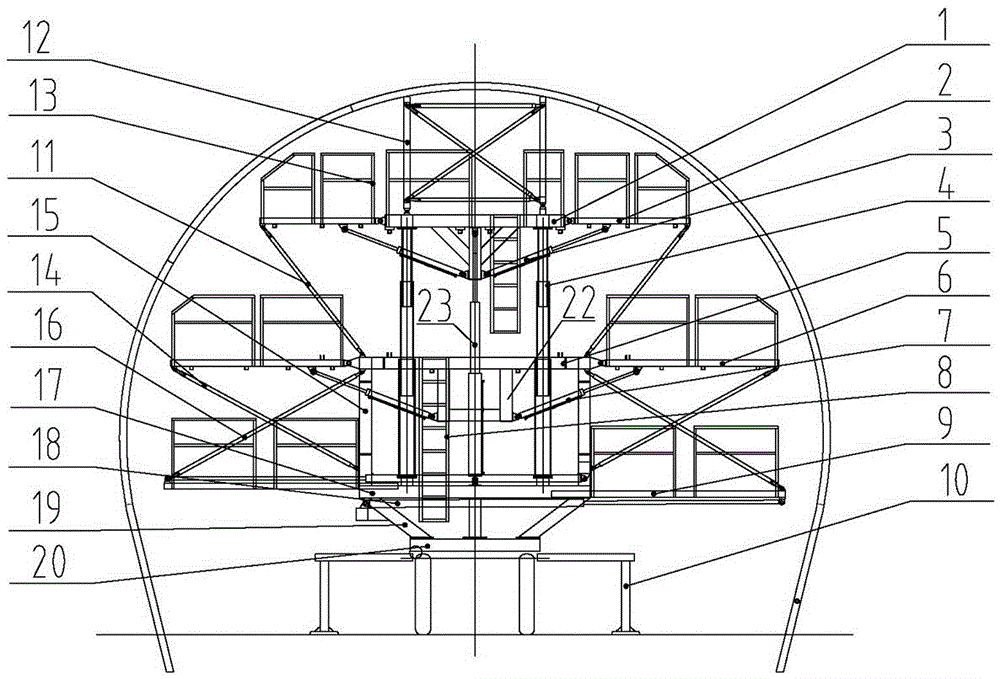

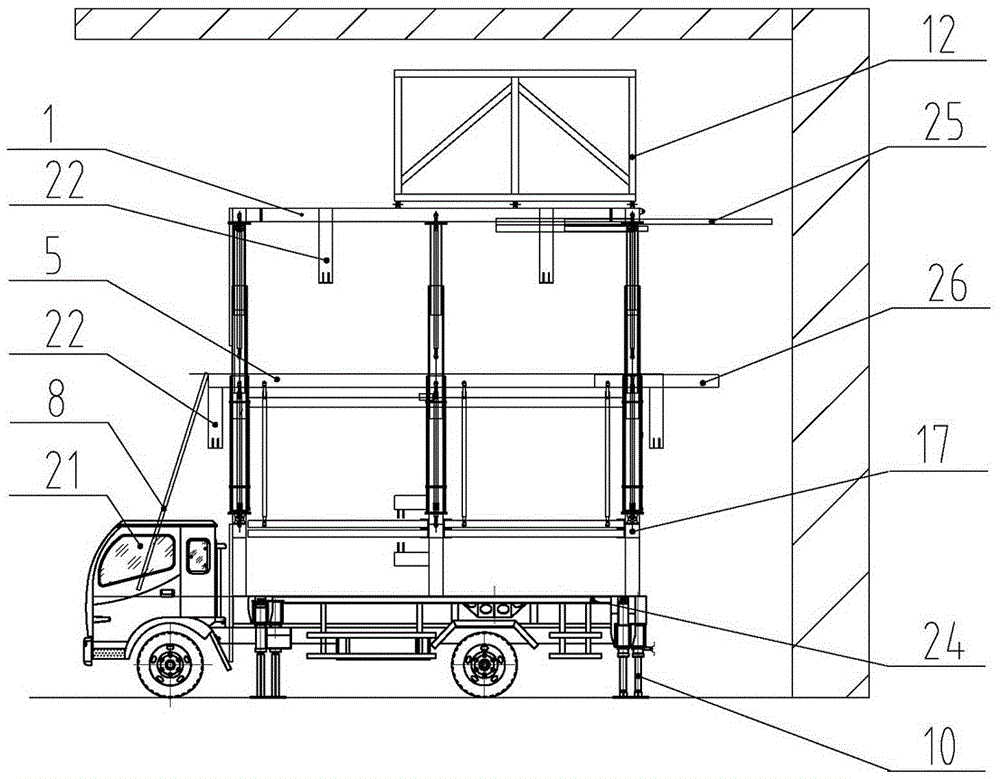

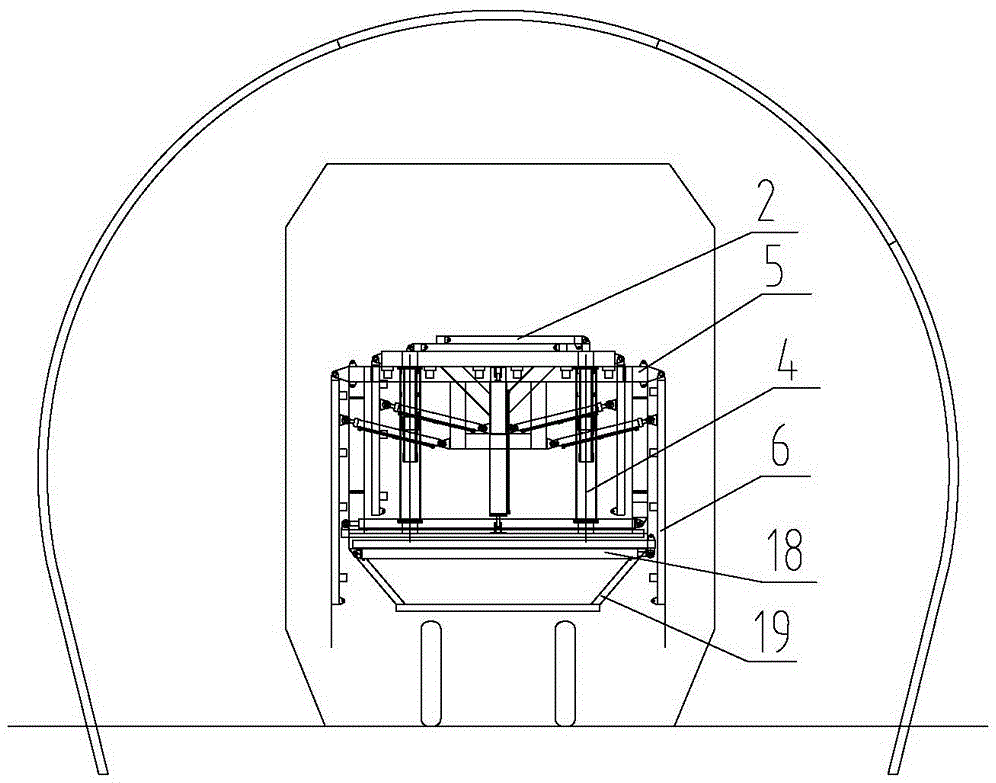

[0015] Such as figure 1 , figure 2 As shown, the tunnel vehicle-mounted folding multifunctional operating platform of the present invention includes a rear eight-wheeled crane chassis 24 with a cab 21 and outriggers 10, a vehicle-mounted hydraulic system, a number of operating platforms with three layers of safety guardrails 13, and operating platforms Ladder 8 between floors. The present invention welds some flanges on the chassis beam 20 of the crane chassis 24, and each flange is bolt-connected with a reinforced diagonal brace 19. The tops of all reinforced diagonal braces 19 are threadedly connected to the lower beam 17 of the fixing frame through flanges. The lower beam 17 of the fixed frame is installed with the upper beam 5 of the fixed frame by several fixed columns 15 . The chassis beam 20, the reinforced diagonal brace 19, the lower beam 17 of the fixed frame, the fixed column 15 and the upper beam 5 of the fixed frame constitute a fixed main support structure. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com