Retractable concrete arch and anchor rod combined support system and construction method

A combined support and concrete technology, applied in the installation of bolts, earthwork drilling, wellbore lining, etc., can solve the problems of low rigidity, slow construction speed, and high labor intensity of anchor net and cable support, and achieve the support structure. Simple and reliable, low labor intensity of workers, high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

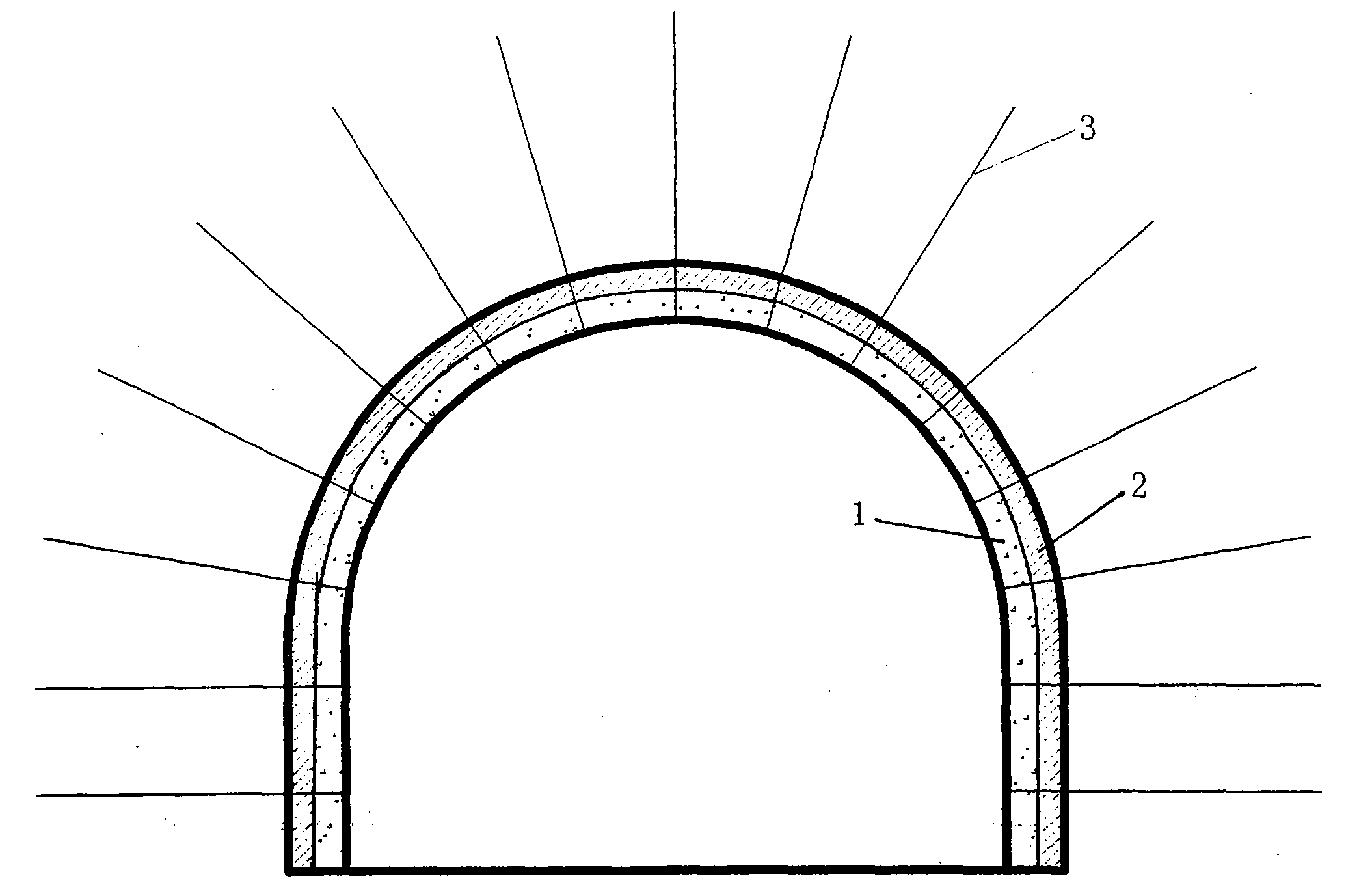

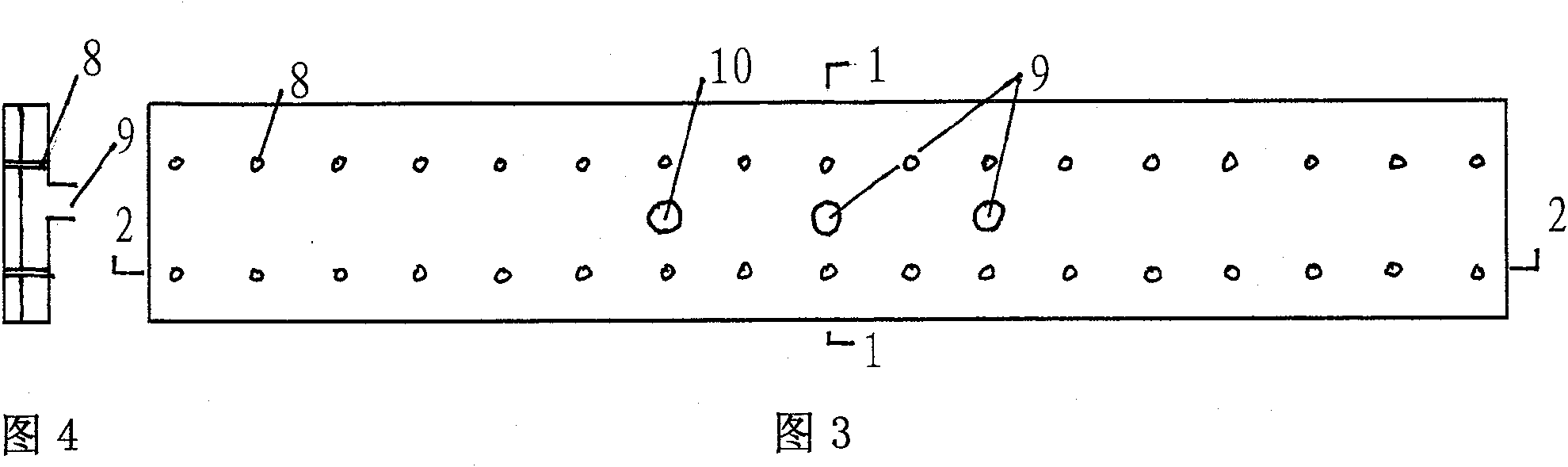

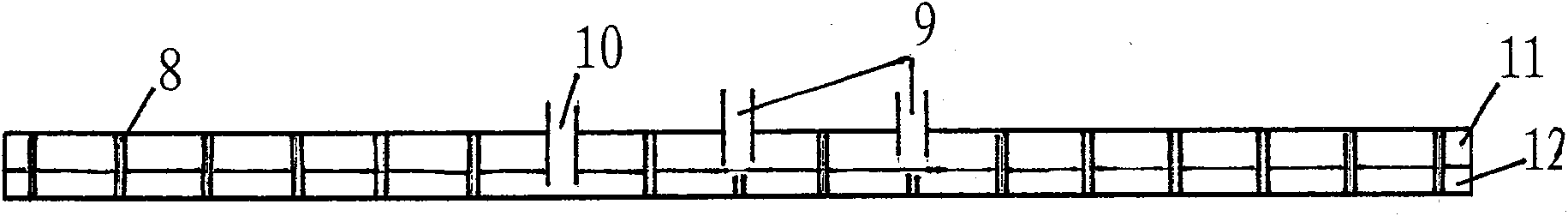

[0039] A combined support system of shrinkable concrete slabs and bolts, the double-layer fiber flexible formwork 5 is made of high-strength fiber cloth according to the length of the tunnel perimeter to make a cuboid structure, with bolt holes 8 and inner pouring ports 9 And the outer pouring port 10, during construction, the double-layer fiber flexible formwork 5 is continuously laid close to the surrounding rock, the inner side of which is laid with a reinforcement mesh 6, the anchor rod 3 passes through the reinforcement mesh 6, and the double-layer fiber flexible formwork 5 is connected with the surrounding rock 4, Concrete 1 is pumped into the inner space 11 of the double-layer fiber flexible formwork 5 through a concrete pump through the delivery pipe and the inner layer pouring port 9 to form a concrete layer, and after the concrete 1 is solidified, it is pumped into the outer space 12 of the double-layer fiber flexible formwork 5 Injecting foamed concrete forms a highl...

Embodiment 2

[0041] A combined support system of shrinkable concrete slabs and bolts, the double-layer fiber flexible formwork 5 is made of high-strength fiber cloth according to the length of the tunnel perimeter to make a cuboid structure, with bolt holes 8 and inner pouring ports 9 And the outer pouring port 10, the double-layer fiber flexible formwork 5 is laid at intervals close to the surrounding rock 4 during construction, and the steel mesh 6 is laid outside it, the anchor rod 3 passes through the steel mesh 6, and the double-layer fiber flexible formwork 5 is connected to the surrounding rock 4 , and there is a row of anchor rods 14 between two adjacent double-layer fiber flexible formworks 5, and the concrete pump is used to pump concrete 1 to the inner space 11 of the double-layer fiber flexible formwork 5 through the delivery pipe and the inner layer pouring port 9 to form a concrete layer. After the concrete 1 is solidified, foamed concrete is pumped into the outer space 12 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com