Strengthening and reinforcing method of high-ground-pressure soft rock laneway by hierarchical grouting

A high ground pressure, layered technology, applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of difficult plugging, less secondary grouting, insufficient grouting depth, etc., to improve diffusion uniformity, guarantee Construction safety, improve the effect of strengthening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

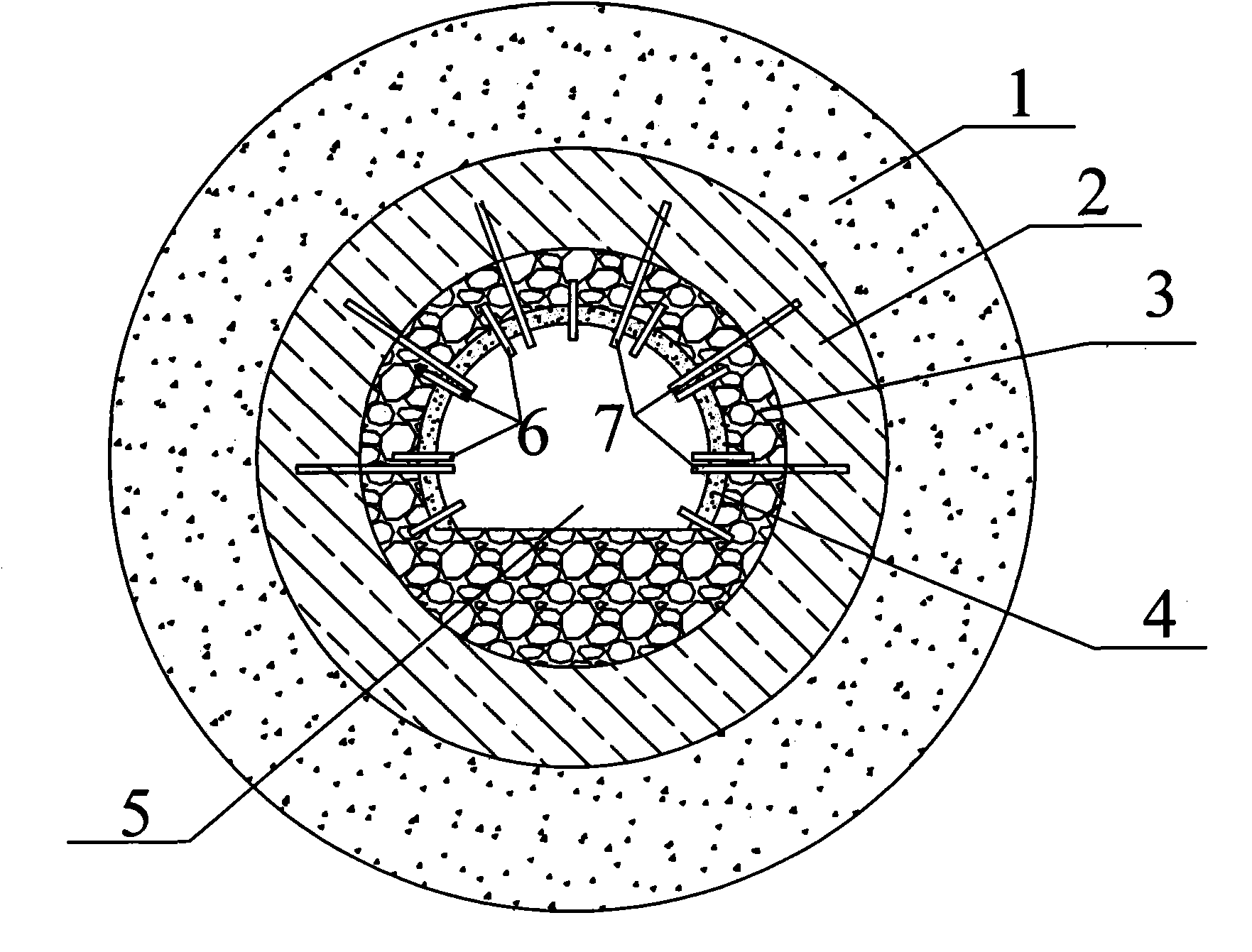

[0014] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

[0015] (1) Immediately following the roadway 5 excavation head-on, install the deep hole grouting pipe 7 with a length of about 3m and a row spacing of about 4.0×4.0m and a length of about 0.8m and a row spacing of about It is a shallow-hole grouting pipe 6 of 1.5m×1.5m, which should be sealed in time after installation to prevent the mouth of the pipe from being blocked by grouting on the surface of the roadway;

[0016] (2) After the shallow hole grouting pipe 6 and the deep hole grouting pipe 7 are installed, the surface of the roadway 5 is sprayed and sealed to form the roadway surface shotcrete layer 4, and the surface rock mass of the closed roadway is required to be uniform and compact. The thickness of the grouting layer is 120mm. If the grouting fails to meet the requirements at one time, it can be re-sprayed to prevent grout leakage during grouting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com