Method for controlling large deformation by releasing pressure of high-stress roadway surrounding rocks

A control method and technology for surrounding rock deformation, which can be used in tunnels, earthwork drilling, mining equipment, etc., and can solve the problems of unsatisfactory support effect and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

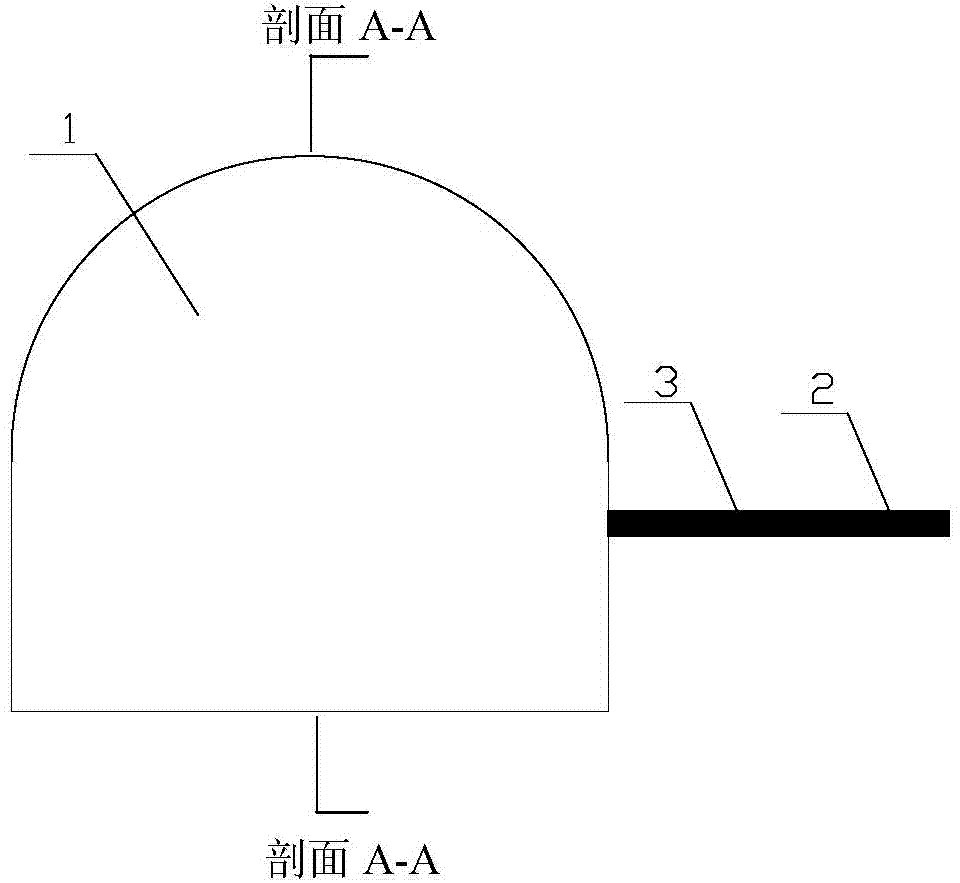

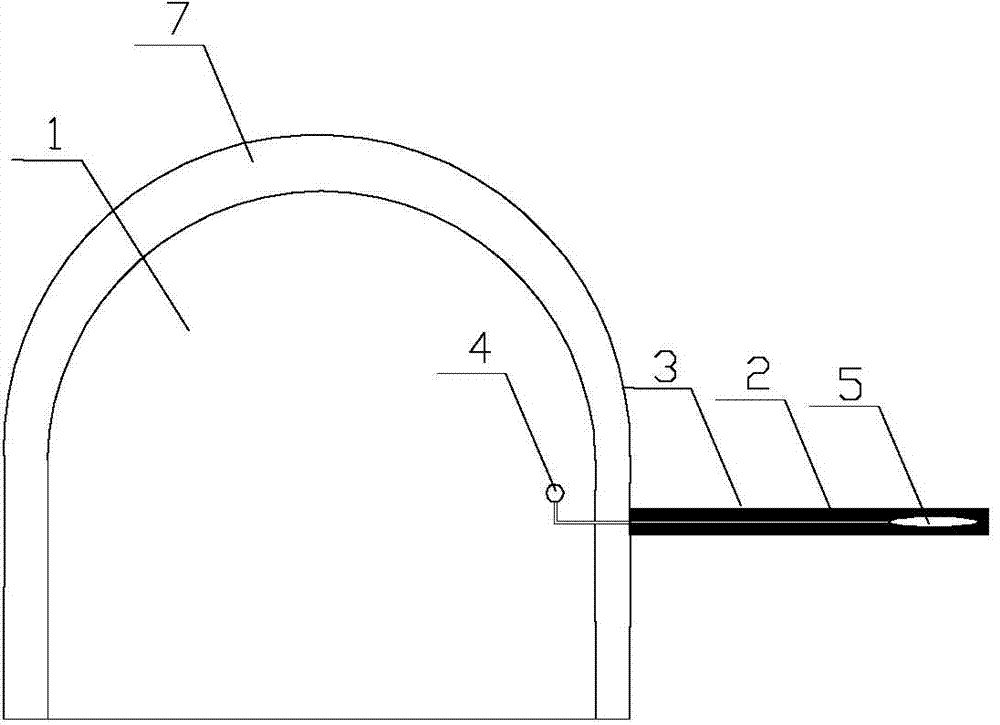

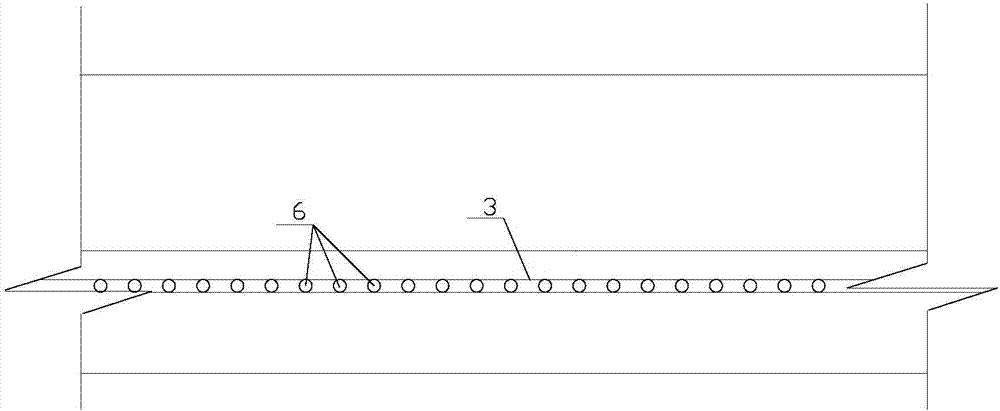

[0021] The present invention will be further described below in conjunction with the accompanying drawings. The difference between the two forms of high-stress surrounding rock in roadway ① rock burst type high-stress surrounding rock and ② large deformation type high-stress surrounding rock:

[0022] (1) Judgment criteria

[0023] The manifestation of high stress in rock burst is rock burst, which is one of the most serious natural disasters in coal mines all over the world. The disaster is to release the deformation energy of the coal and rock mass in a sudden, sharp and violent form. The coal and rock mass is thrown out, causing damage to the support, roof collapse of the roof, blockage of the roadway, injury to personnel, and huge noise and vibration of the rock mass. The time ranges from a few seconds to tens of seconds.

[0024] The performance form of large deformation type high stress surrounding rock is large amount of deformation, and the internal stress of the sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com