Control method for coal mine insular coal pillar crossheading rock burst

A control method and technology of rock burst, applied in ground mining, underground chambers, mining equipment, etc., can solve problems such as insufficient degree of relief, unsafety, local stress concentration, etc., and achieve the goal of improving strength and protecting safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

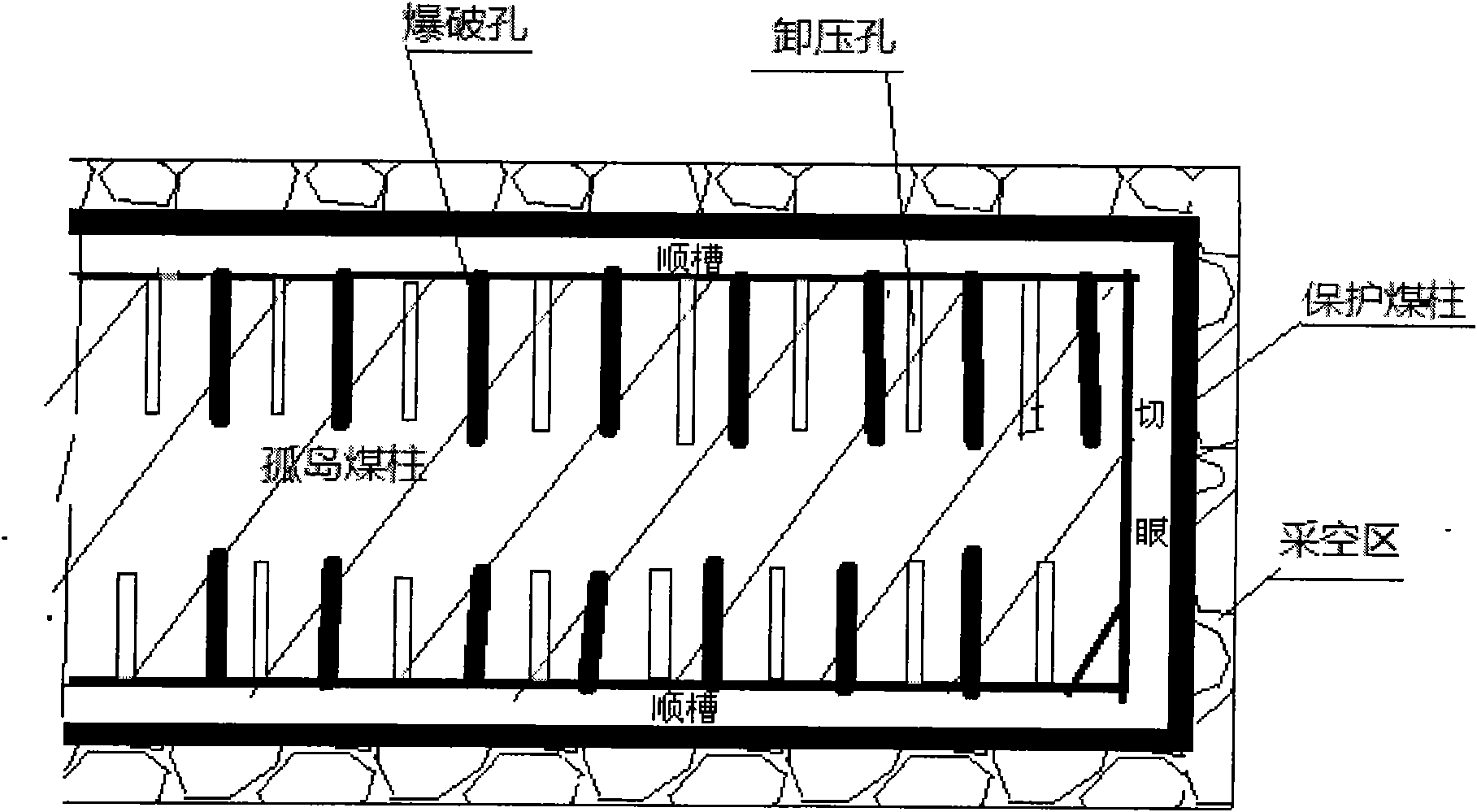

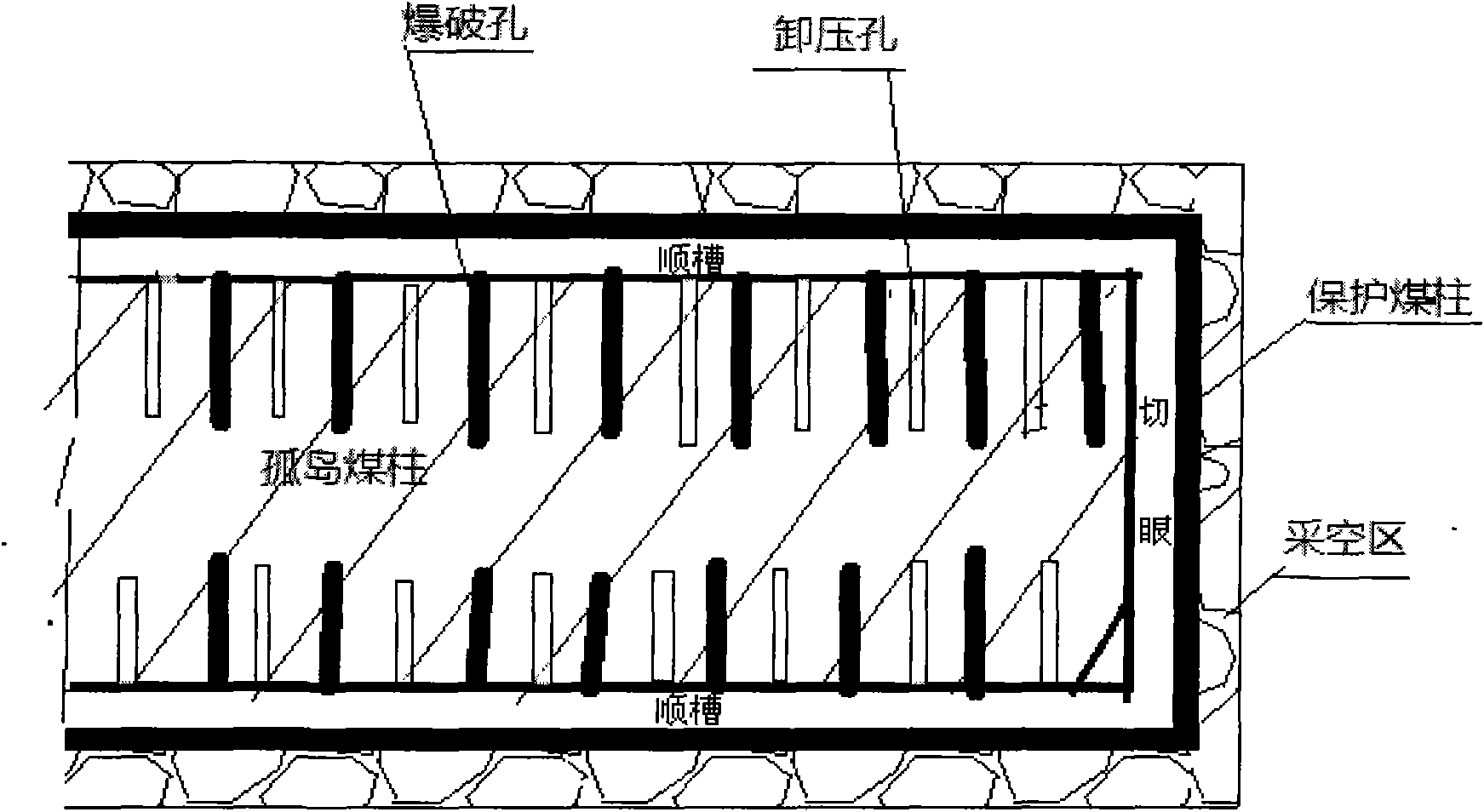

[0019] Such as figure 1 As shown, the specific steps of the method for controlling rock burst along the groove of coal mine island coal pillars of the present invention are:

[0020] Step 1: Develop mining roadways for arranging isolated coal pillars in coal mines

[0021] The mining roadway of the coal pillar in the isolated island of the coal mine includes the upper and lower troughs and the cutting holes of the working face. Excavate the roadways that meet the needs of production and ventilation; the cutting holes of the working face are arranged along the edge of the goaf, and generally leave a protective coal pillar of about 3m.

[0022] The second step: if figure 1 As shown, drilling and blasting pressure relief is carried out on the inner side of the upper and lower grooves

[0023] On the inner side of the upper and lower grooves at a height of 1.0-1.3m from the roadway floor, a drill hole is arranged every 3.0m. The diameter of the drill hole is 42mm, the depth of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com