Mechanized continuous mining method for wall-type gentle-inclined thin ore body

A mining method and thin ore body technology, applied in the field of mechanized continuous mining of wall-type gently inclined thin ore bodies, can solve the problems of poor production safety, high consumption of production materials, low ore recovery rate, etc., and achieve high production efficiency and mechanized operations High degree, the effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

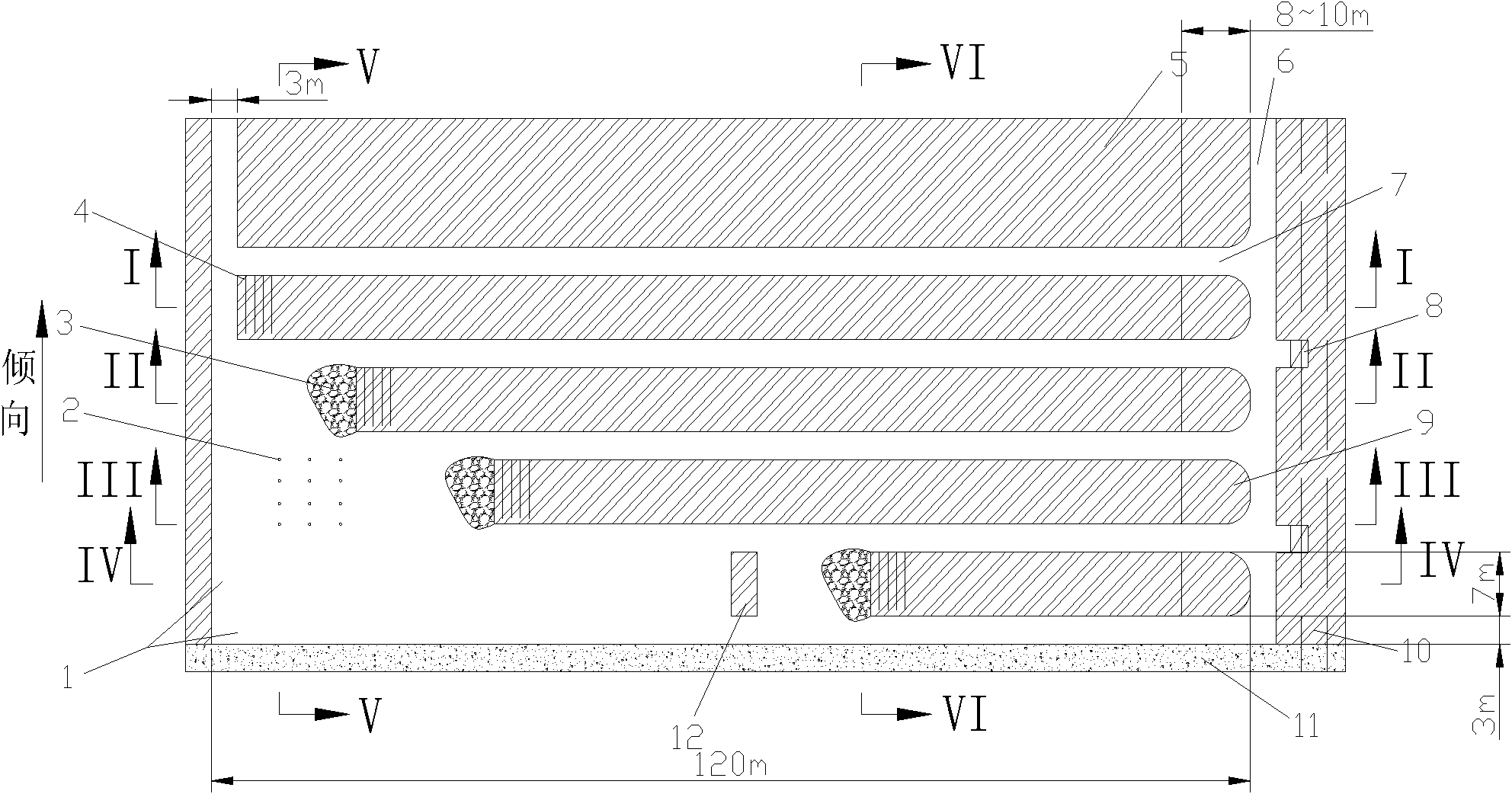

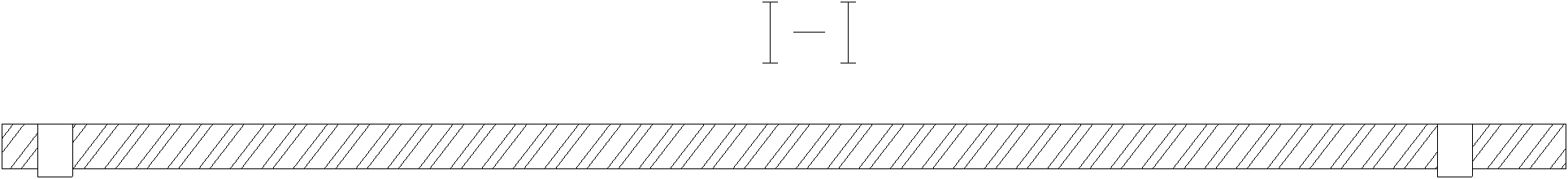

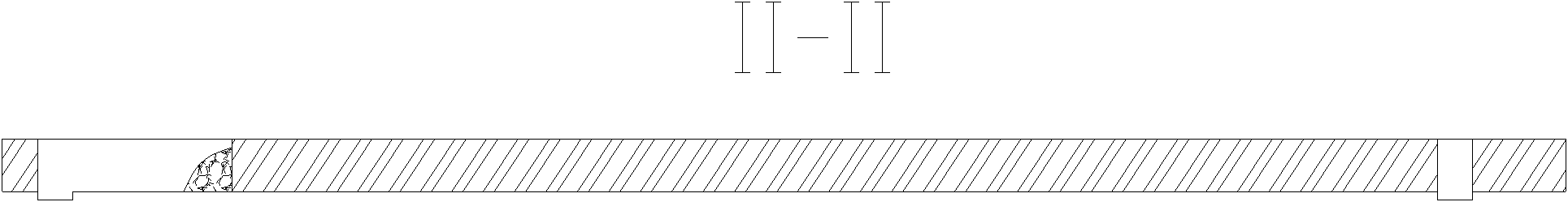

[0022] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 , in the figure: 1. ventilation roadway, 2. hydraulic prop, 3. ore, 4. blast hole, 5. ore body, 6. transportation roadway, 7. rock drilling roadway, 8. slip shaft, 9. security pillar, 10 . Concentrated transport roadway, 11. Surrounding rock, 12. Ore pillars, the stope is arranged along the vertical direction of the ore body, the stope structural parameters are 120m in length, 7m in width, 3m in height or the thickness of the entire ore body, and the interval column between the panels That is, the security pillars of the transport roadway, and the width of the pillars between panels is 5-8m. Due to the large exposed area of the roof, hydraulic props 2 are set up during the mining process to manage the ground pressure in the working stope, and according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com