Method for controlling underground sliding sleeves by ground pressure waves

A ground control and pressure wave technology, which is applied in wellbore/well valve device, earthwork drilling, wellbore/well components, etc. Conducive to post-production, low cost, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A method for controlling a downhole sliding sleeve by surface pressure waves, comprising the steps of:

[0052] a. Multiple sliding sleeves are connected to the completion string at the same time, and each sliding sleeve is assigned different command information to run into the well;

[0053] b. Regularly adjust the displacement of surface pumps to make the downhole pressure change according to the same law, that is, to transmit the pressure fluctuation signal containing control instructions to the downhole;

[0054] c. The receiving device installed on each sliding sleeve receives the ground control command and compares it with the command information assigned by itself;

[0055] d. If the ground control command is different from the command information assigned inside the sliding sleeve, the sliding sleeve will not act and continue to wait for the next ground control command;

[0056] e. If the ground control command is the same as the command information distributed...

Embodiment 2

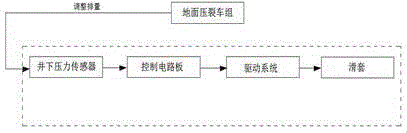

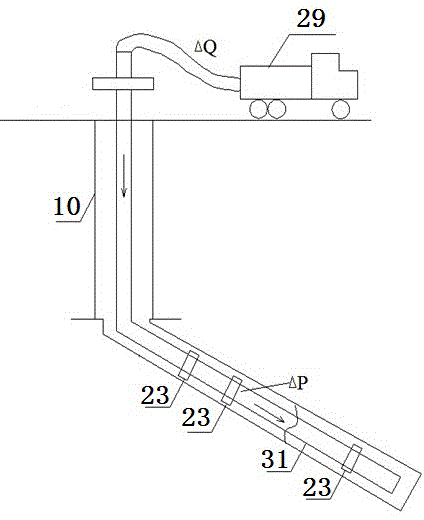

[0082] The invention is divided into two parts: a surface control part and a downhole execution part. The ground control part is the fracturing train unit; the downhole part is the executive part, which is an electronically controlled switchable sliding sleeve. In order to meet the needs of the current staged fracturing and acidizing process for horizontal wells, usually, multiple electrically controlled switchable sliding sleeves are connected to the completion string of a well at the same time, and they are lowered into the well together. Different instruction information is assigned, and when the ground fracturing crew adjusts the surface pumping displacement according to a certain law, the downhole pressure will also change according to the same law, that is, pressure fluctuations containing control instructions are transmitted downhole. The pressure sensor installed on each sliding sleeve receives the ground control command and compares it with the command information ass...

Embodiment 3

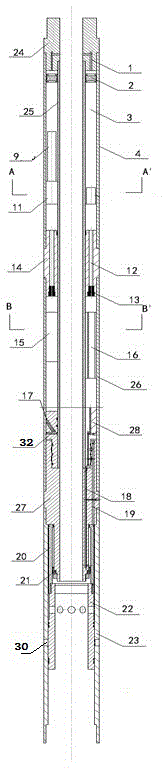

[0086] In this embodiment, the switch control of the sliding sleeve is described in detail as follows:

[0087] Switch sliding sleeve closed state:

[0088] Start the motor 9 according to the control signal, and the two-position three-way electromagnetic reversing valve 5 is in a power-off state and is in the lower position; the high-pressure oil enters the lower oil passage 18 through the second two-position two-way electromagnetic reversing valve 7 and the lower circuit, and pushes the valve. 22 moves upwards, the first two-position two-way electromagnetic reversing valve 6 is electrified, and when valve 22 moves upward, the hydraulic oil in the upper oil passage is pushed along the upper circuit, and returns to the oil tank 3 through the first two-position two-way electromagnetic valve 6, The sliding sleeve is closed. The upper space of the upper piston 2 on the fuel tank 3 communicates with the external environment pressure, thereby keeping the pressure in the fuel tank 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com