Surface control well sliding sleeve for staged fracturing and acidizing reconstruction of horizontal wells

A staged fracturing and surface control technology, applied in wellbore/well components, wellbore/well valve devices, production fluids, etc., can solve problems such as poor timeliness and sliding sleeves that cannot be closed, and achieve Low cost, conducive to post-production, large diameter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

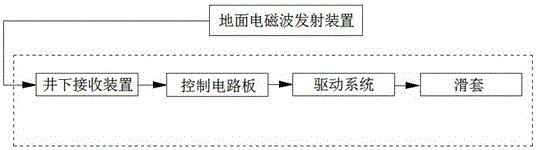

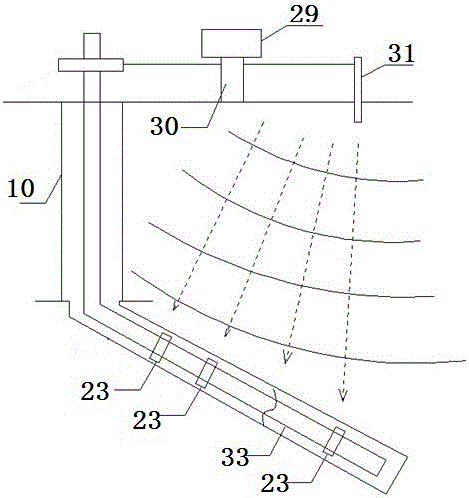

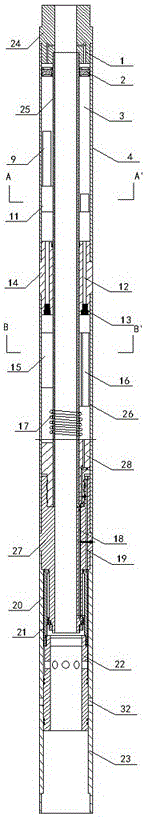

[0048] A ground-controlled downhole sliding sleeve for staged fracturing and acidification reconstruction of horizontal wells, comprising a ground electromagnetic wave emitting device and a switch sliding sleeve, the switch sliding sleeve including an electromagnetic wave receiving device, a drive system and a sliding sleeve 23, the electromagnetic wave receiving device and The driving system is arranged on the sliding sleeve 23, and the shell of the sliding sleeve 23 has an injection hole 32, and the valve 22 of the sliding sleeve 23 has an injection hole 32; the ground electromagnetic wave transmitting device sends command information, and the electromagnetic wave receiving device Receive the instruction information sent by the electromagnetic wave emitting device and control the drive system to drive the valve 22 to move; when the valve 22 moves to the valve hole and the shell injection hole communicates, the sliding sleeve 23 is in an open state, and the valve 22 moves to W...

Embodiment 2

[0072] The invention is divided into two parts: a surface control part and a downhole execution part. The ground control part is an electromagnetic wave emitting device; the downhole part is an execution part, which is a switch sliding sleeve. In order to meet the needs of the current staged fracturing and acidizing process for horizontal wells, usually, multiple electrically controlled switchable sliding sleeves are connected to the completion string of a well at the same time, and they are lowered into the well together. Different instruction information is assigned. When the ground electromagnetic wave launcher sends a control instruction, each sliding sleeve receives the ground control instruction, and at the same time compares it with the instruction information assigned by itself. If the command information is different, the sliding sleeve will not act. If the ground control command is the same as the command information distributed inside the sliding sleeve, the sliding...

Embodiment 3

[0076] In this embodiment, the switch control of the sliding sleeve includes the following steps:

[0077] a. Multiple sliding sleeves are connected to the completion string at the same time, and each sliding sleeve is assigned a different control command to run into the well;

[0078] b. The ground electromagnetic wave transmitting device generates command information to control the opening or closing of multiple downhole sliding sleeves according to the input control commands, and the command information is amplified and then sent to the downhole sliding sleeves;

[0079] c. The electromagnetic wave receiving device installed in each downhole sleeve receives the command information sent from the ground, and compares the command information with the respective pre-allocated control commands;

[0080] d. If the command information is inconsistent with the control command assigned by the downhole sleeve, the downhole sleeve whose command information does not match will not act,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com