U-shaped steel composite support structure for deep dynamic pressure soft rock roadway and construction method of U-shaped steel composite support structure

A composite support and construction method technology, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems that the support cannot play a supporting role in time, the initial support force cannot be applied to the surrounding rock, and the deformation of the surrounding rock can be solved. Economical effect, flexible and changeable support form, and the effect of avoiding local damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

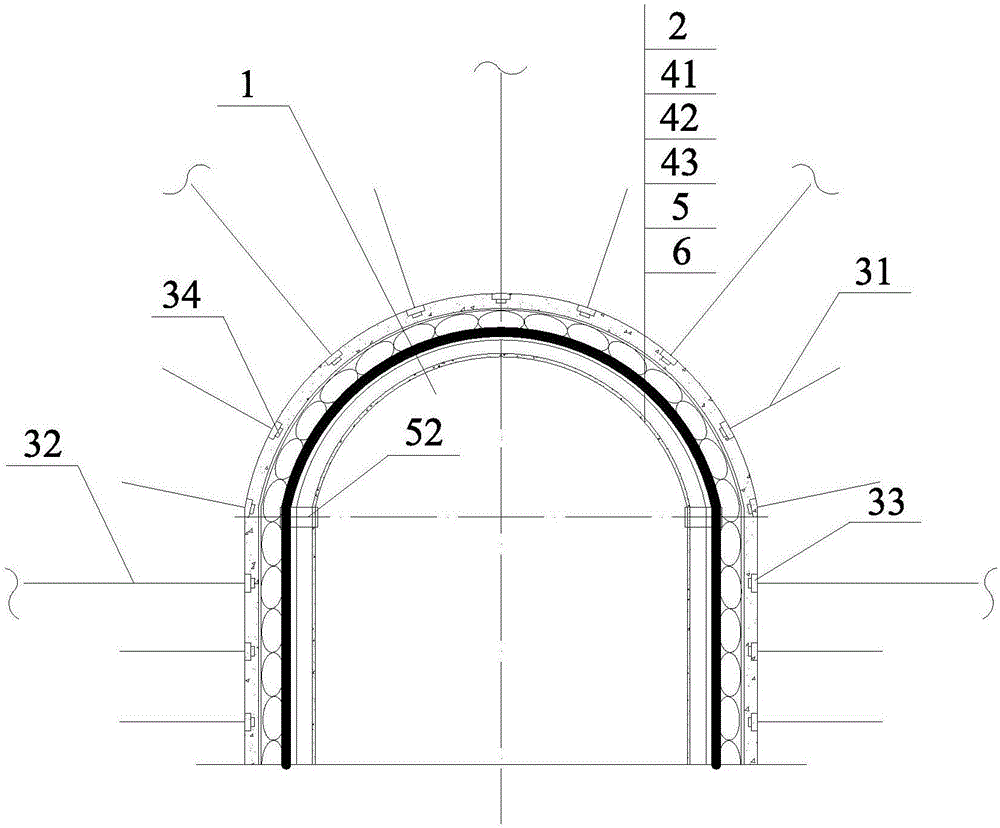

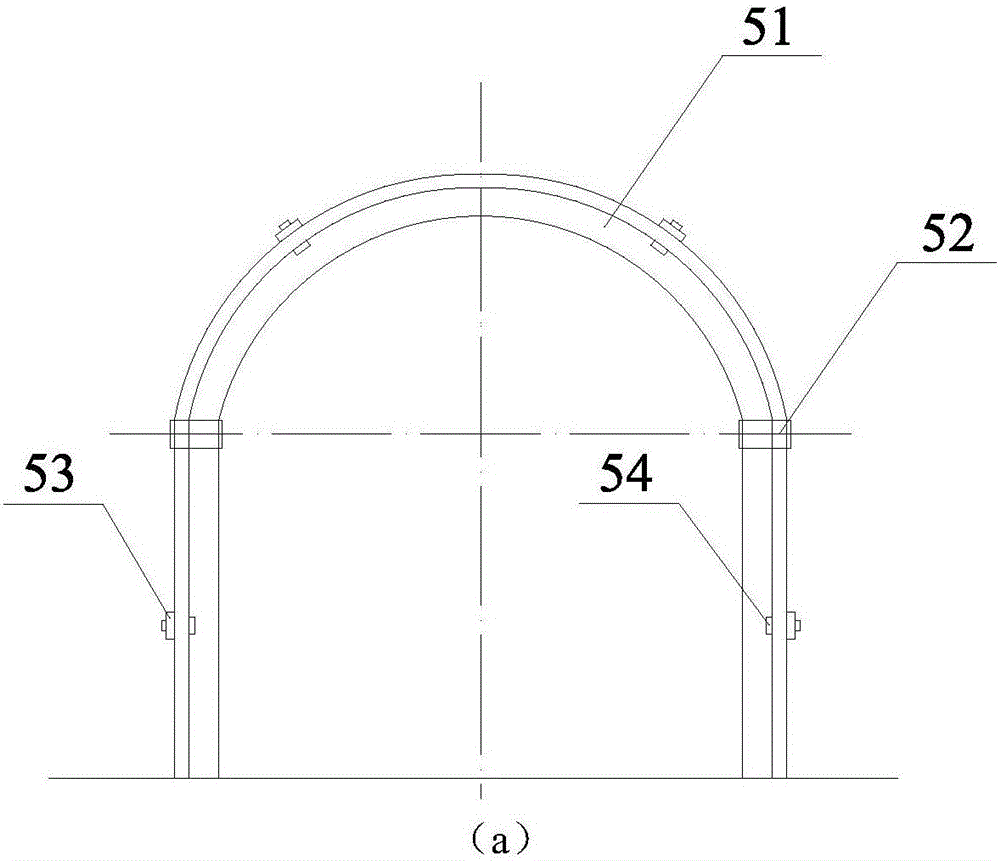

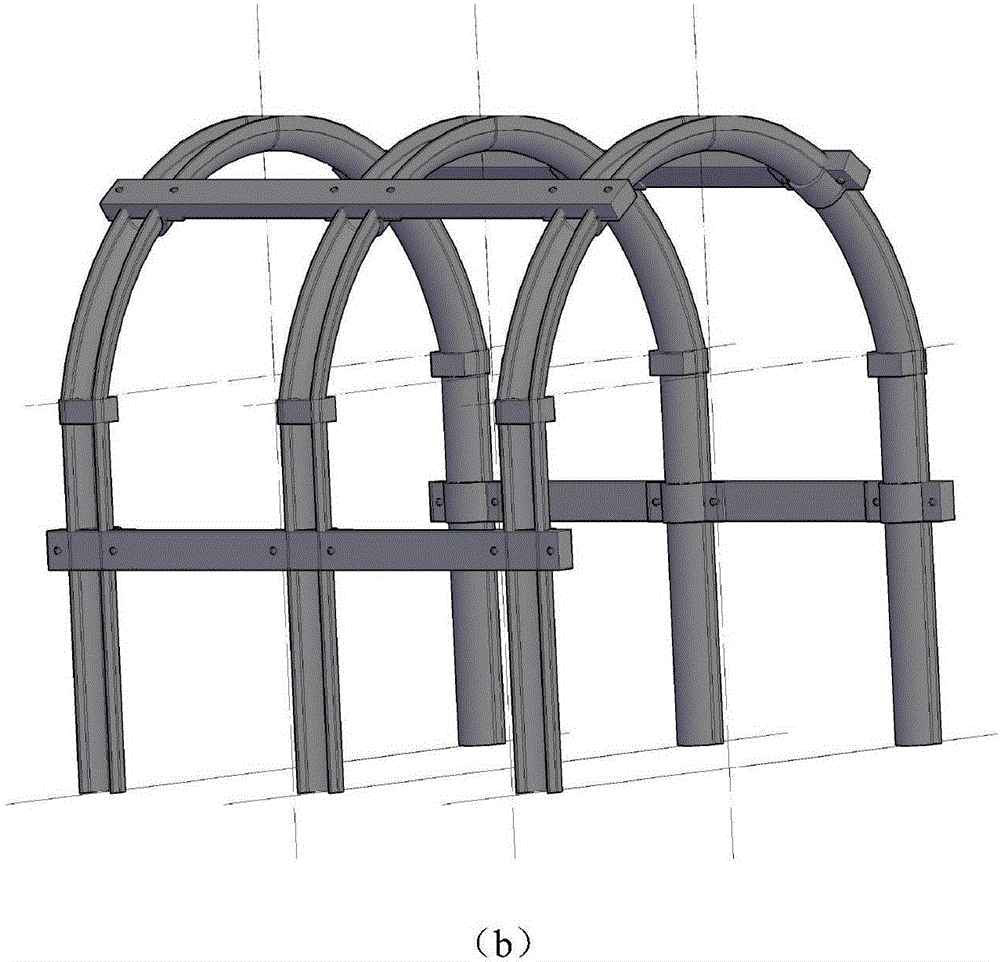

[0056] refer to Figure 1~4 , the construction steps, methods and related parameters are as follows:

[0057] A) Excavate roadway 1 according to the design section shape and size of roadway 1, and spray 50mm thick concrete leveling layer 2 on the section of roadway 1, the design strength is not lower than C20, and the mix ratio is cement: melon seeds: sand: water = 1:2 : 2: 0.45, and mixed with 2.5% cement amount of quick-setting agent;

[0058] B) After the initial setting of the concrete leveling layer, use the anchor rod 31 and the anchor cable 32 to drive into the interior of the surrounding rock 1 and expose it, and fix it with the tray 33 and the nut 34. The specification of the tray 33 used is 150mm×150mm×150mm. Not less than 150kN, the anchor rod 31 used is a high-strength prestressed anchor rod with a diameter of Φ20mm, a total length of 2400mm, a spacing of 700mm, and a row spacing of 700mm. , total length 7000mm, such as figure 1 As shown, one is arranged on the ...

Embodiment 2

[0062] refer to Figure 5 with Image 6 , on the basis of Embodiment 1, if the surrounding rock is relatively broken and accompanied by the phenomenon of undercutting, it is further preferable to add grouting construction equipment and anti-bottom arches, and the increased construction steps, methods and related parameters are as follows:

[0063] E) If Figure 5 As shown, in step B) of Embodiment 1, a plurality of hollow grouting anchor rods 35 and hollow grouting anchor cables 36 are arranged, and the grouting construction is carried out after the roadway 1 is excavated to form a grouting layer 37, inject The slurry material is clay cement slurry;

[0064] F) Excavate 500-600mm downward from the roadway 1 floor, and then drive the anchor rod 31 to the bottom plate of the roadway 1 and fix it with the tray 33 and the nut 34, and lay the latticed steel mesh anti-bottom arch 71, which consists of a diameter of Φ10mm It is made of welded steel bars, and a buffer layer 72 is s...

Embodiment 3

[0068] refer to Figure 7 with Figure 8 , on the basis of Embodiments 1 and 2, if the ground pressure of the vault and the two sides of the roadway 1 is strong and accompanied by large deformation, it is further preferable to add support columns, and the additional construction steps, methods and related parameters are as follows:

[0069] G) support column 8 is set, and support column 8 is steel pipe concrete column, and the diameter of steel pipe is 300mm, and concrete design strength is C30, and mix ratio is cement: melon seed slice: sand: water=1:2:2:0.45, Figure 7 (a), (b), and (c) are respectively the structural schematic diagrams of the support column 8 being an upright column 81, a "Y" shaped column 82 and a "T" shaped column 83.

[0070] Figure 8 Shown is the structural schematic view of the upright column 81 implemented on the present invention.

[0071] In fact, the construction method, steps and relevant parameters are the same as those in Embodiments 1 and 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Carrying capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com