Automatic wall-forming device and method of static pressure continuous concrete wall

An underground diaphragm wall and automatic wall forming technology, which is applied to underwater structures, water conservancy projects, artificial islands, etc., can solve problems such as high price support, environmental pollution, and poor comprehensive economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

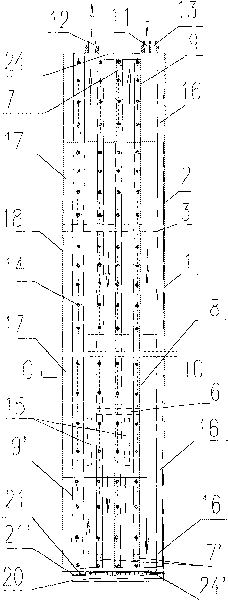

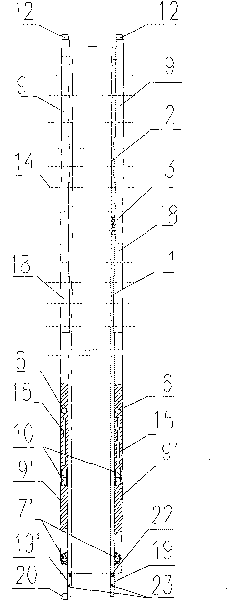

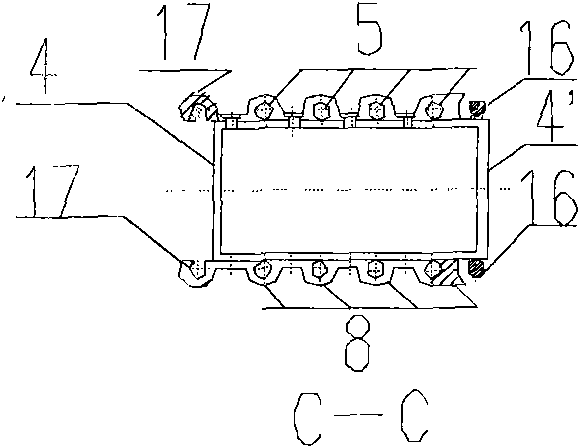

[0016]The automatic wall-forming device of this embodiment consists of three parts: basic body, docking body, and valve group; its basic body part includes basic section 1, connecting section 2, wedge-shaped interface 3, short side surface 4, and short side surface 4' , main channel 5, cable cross channel 6, cooling water circulation channel 7, cooling water circulation channel 7', corrugated plate 8, top corrugated plate 9, end corrugated plate 9', sealing strip 10, water inlet joint 11, water outlet Connector 12, cable inlet 13, connecting screw 14, vibrator 15, connecting corrugated plate 18, upper blocking 24 and lower blocking 24'; main functions are: 1, the main body of force and force transmission, 2, the mixture carrier and Wall section shape mold, 3. Butt joint body and valve group parts placement base; the long side of the basic body section is 300mm-1200mm, the short side is 100mm-1000mm, and its surface shape has a combined trapezoidal plate shape, thick-walled stra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com