Method for using blast furnace gas to heat of large-scale walking beam type plate blank heating furnace

A blast furnace gas and slab heating technology, which is applied in the field of blast furnace gas heating and slab heating in wide and thick plate engineering, can solve the problems of no natural gas pipeline, increased cost, natural gas can not meet the natural gas consumption requirements, etc., achieve significant environmental protection effect and reduce emissions , Huge energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

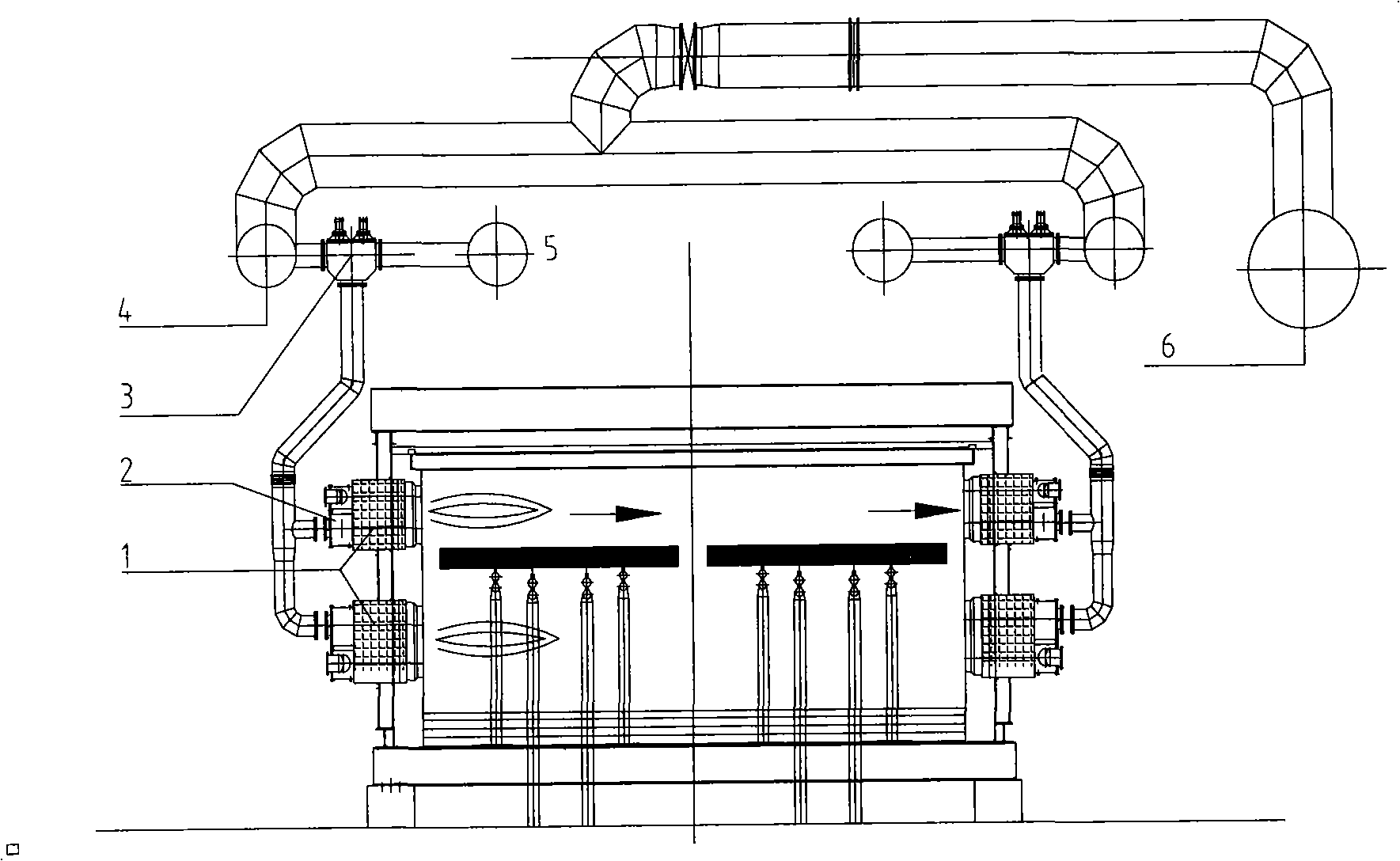

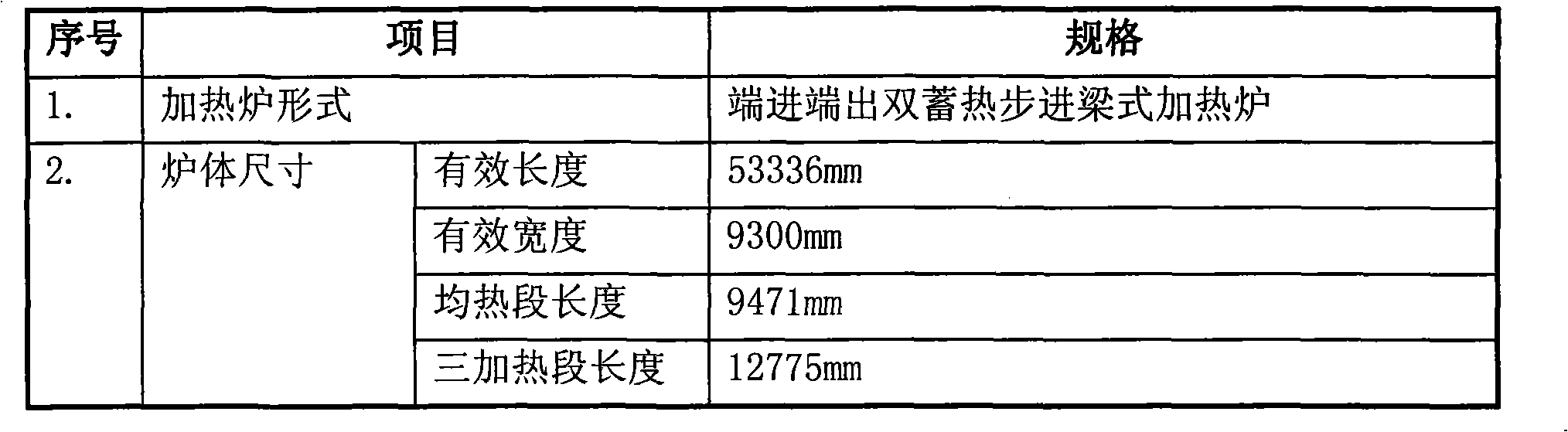

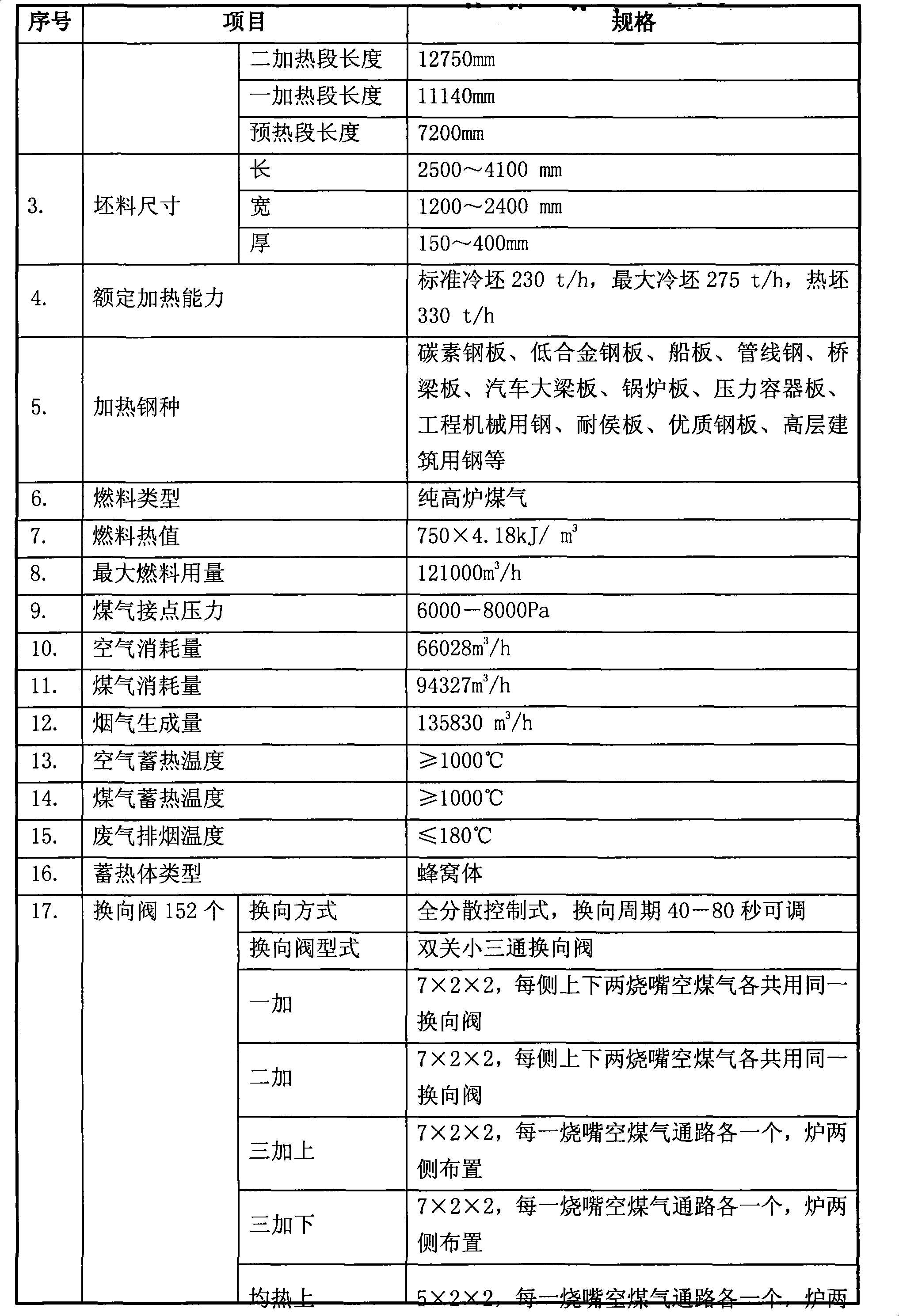

[0027] The key heating technology of the regenerative heating furnace lies in the organic combination of the fuel consumption system and the rehearsal system. The wide and thick plate engineering heating furnace adopts the regenerative combustion technology. The regenerative burners are arranged in pairs. The air from the blower and the blast furnace The blast furnace gas sent to the furnace body by the main gas pipeline is heated when it is switched into the regenerative burner through the reversing valve. In a very short period of time, the normal temperature blast furnace gas and air are heated to close to the furnace temperature. After the gas and air enter the furnace, the flue gas in the surrounding furnace is entrained to form a thin oxygen-deficient high-temperature airflow with an oxygen content much lower than 21%, and at the same time, the thin high-temperature air and high-temperature blast furnace gas are burned in an oxygen-depleted state; At the same time, the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com