Polyurethane lens forming adhesive tape and preparation method thereof

A polyurethane and lens technology, applied in adhesives, film/sheet release coatings, film/sheet adhesives, etc., can solve problems such as bubbles in polyurethane lenses, achieve the effect of solving bubbles and meeting process temperature requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

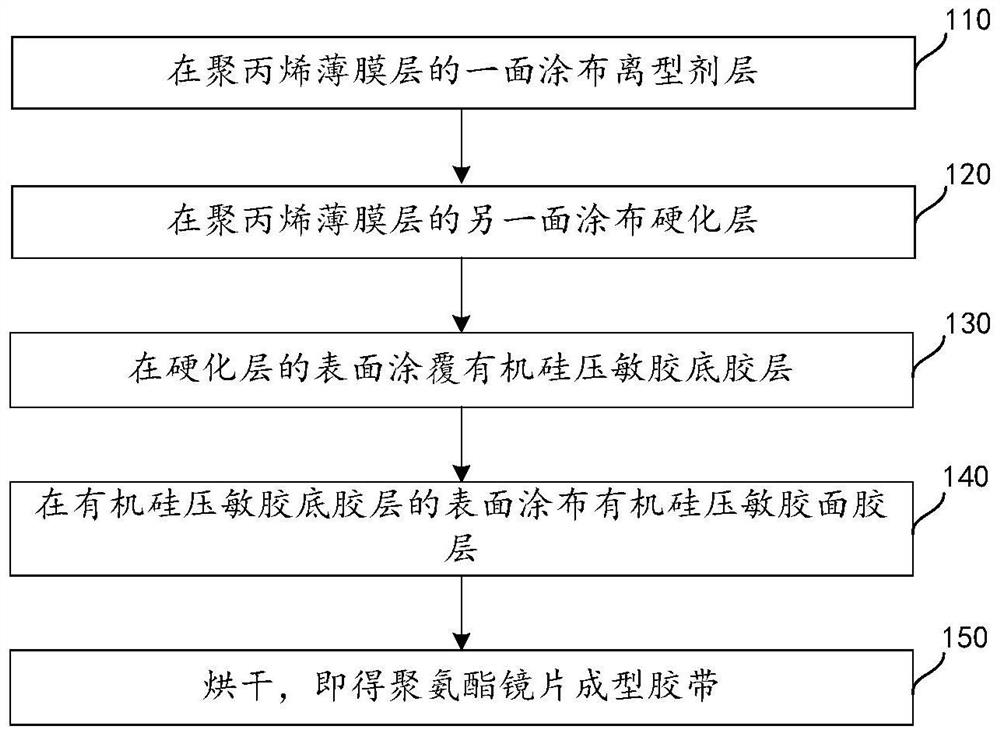

Method used

Image

Examples

Embodiment 1

[0057] The polypropylene film layer selected in this embodiment is a single-layer polypropylene film, and the thickness of the single-layer polypropylene film is 0.05 mm. Specific steps are as follows:

[0058] 1. Prepare the release agent solution, the release agent is preferably alkyl urethane modified polyvinyl alcohol, dissolve the powdered alkyl urethane modified polyvinyl alcohol with ethyl acetate or toluene, and prepare a mass concentration of 5 %-20% release agent solution.

[0059] 2. Use an anilox roller or dimple coating roller to coat the release agent solution on the surface of the single-layer polypropylene film with a coating thickness of 1 micron. Send the single-layer polypropylene film coated with the release agent solution into the drying tunnel, and dry it for 30 seconds at 130°C. The standard for judging the drying is that the surface is smooth and free of mucus.

[0060] 3. Under normal temperature conditions, put the single-layer polypropylene film co...

Embodiment 2

[0071] The polypropylene film layer selected in this embodiment is a double-layer polypropylene composite film, which is composed of two single-layer polypropylene films, wherein the thickness of the single-layer polypropylene film is 0.05 mm. Specific steps are as follows:

[0072] 1. Prepare the release agent solution, the release agent is preferably alkyl urethane modified polyvinyl alcohol, dissolve the powdered alkyl urethane modified polyvinyl alcohol with ethyl acetate or toluene, and prepare a mass concentration of 5 %-20% release agent solution.

[0073] 2. Coat the release agent solution on the surface of the single-layer polypropylene film with an anilox roll or dimple coating roll, and the coating thickness is 0.5 microns. Send the single-layer polypropylene film coated with the release agent solution into the drying tunnel, and dry it for 30 seconds at 130°C. The standard for judging the drying is that the surface is smooth and free of mucus.

[0074] 3. Put the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com