Pyrolysis and vulcanization beneficiation method for laterite-nickel ore, metal sulfide and application

A technology of metal sulfide and laterite nickel ore, which is applied in chemical instruments and methods, cobalt sulfide, iron sulfide, etc., can solve the problems of large amount of slag in the smelting process and inability to beneficiate laterite nickel ore, so as to improve the comprehensive utilization efficiency of energy, Significant economic and social benefits, the effect of low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

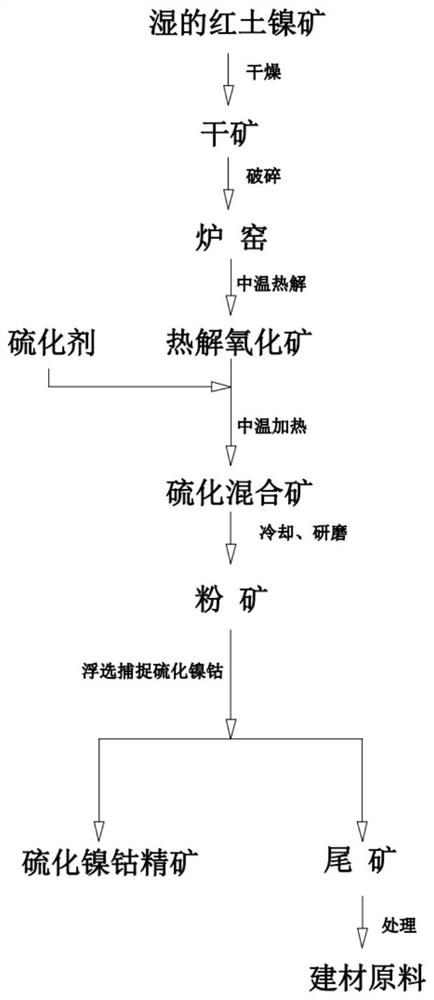

[0066] like figure 1 Shown is the process flow chart of the pyrolysis sulfide mineral processing method of the laterite nickel ore of the present invention; the detailed steps of the pyrolysis sulfide mineral processing method of the laterite nickel ore of the present invention are as follows:

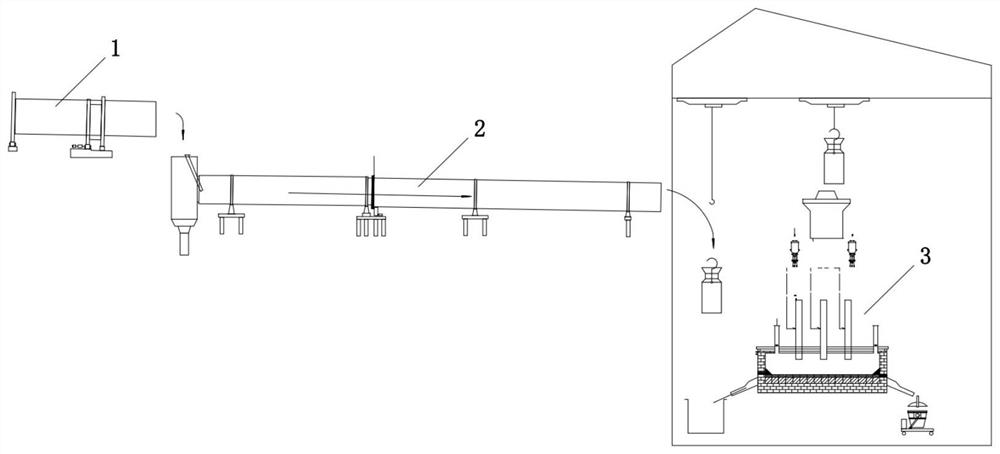

[0067] A smelting project is an integrated project of mining and smelting, and the smelting plant is built in the laterite nickel mining area. Its smelting process adopts 60000Kva ferronickel smelting RKEF process (rotary kiln + electric furnace) and has been built (such as figure 2 ), including drying kiln 1, roasting kiln 2 and submerged thermal electric furnace 3. At present, it is planned to transform the process, utilize the present invention to reduce the amount of slag, and concentrate is added to the electric furnace for smelting.

[0068] The scheme is as follows: After testing, the lateritic nickel ore contains an average of 1.78wt% nickel, 0.03wt% cobalt, 19wt% iron and 38...

Embodiment 2

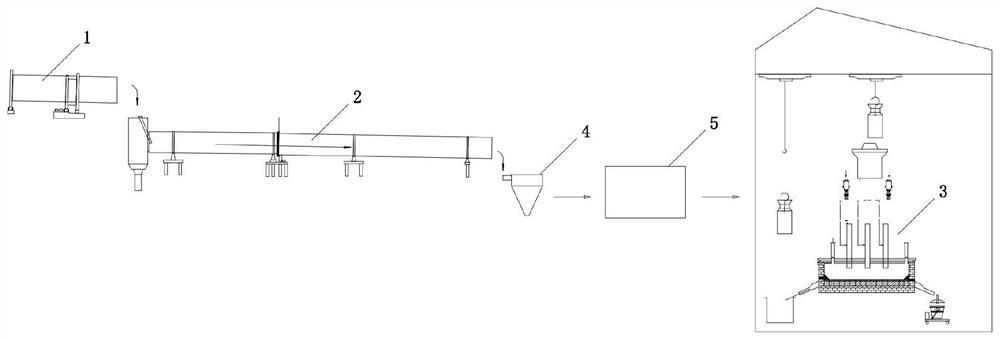

[0075] A smelting project is an integrated project of mining and smelting, and the smelting plant is built in the laterite nickel mining area. Its smelting process adopts 33000Kva ferronickel smelting RKEF process and has been established (such as figure 2 ), including drying kiln 1, roasting kiln 2 and submerged heat electric furnace 3. At present, it is planned to transform the process, first re-election and then flotation to obtain nickel-cobalt concentrate, and then add nickel-cobalt concentrate to electric furnace smelting, thereby reducing the amount of slag in electric furnace smelting. Process equipment diagram after technical transformation image 3 , the main added equipment is gravity hydrocyclone 4 and flotation machine 5. The main process details are improved as follows: reduce the original kiln head temperature of the drying kiln from 600-800°C to 300-500°C; reduce the original rotary kiln head temperature from 1100-1300°C to 500-750°C; Charcoal and anthracite...

Embodiment 3

[0083] A smelting project is an integrated project of mining and smelting. The smelting plant is planned to be built in the lateritic nickel mining area. After testing, the lateritic nickel ore contains an average of 1.65wt% nickel, 0.05wt% cobalt, 26wt% iron and 38% moisture . The beneficiation process adopts the process technology of the present invention, and the nickel-cobalt sulphide smelting process adopts a flash furnace. The main equipment includes drying kiln, vulcanization and roasting kiln, flotation machine, filter press, fine ore dryer, cloth bag collector, pneumatic conveying system, flash furnace, etc. Its main technological process adopts sulfide powder ore to be sprayed into flash furnace to make matte smelting after drying and dust collection.

[0084] The process is as follows: at a drying temperature of 200°C and a drying time of 0.5 hours, dry in a drying kiln until the water content is 25%, then add the dry ore to the roasting kiln, and continuously spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com