Single-medium heating and cooling system

A medium heating and cooling system technology, applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc. , heat medium mixed pollution and other problems, to achieve the effect of facilitating large-scale industrial production and use, increasing the maximum heating temperature and stabilizing the pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

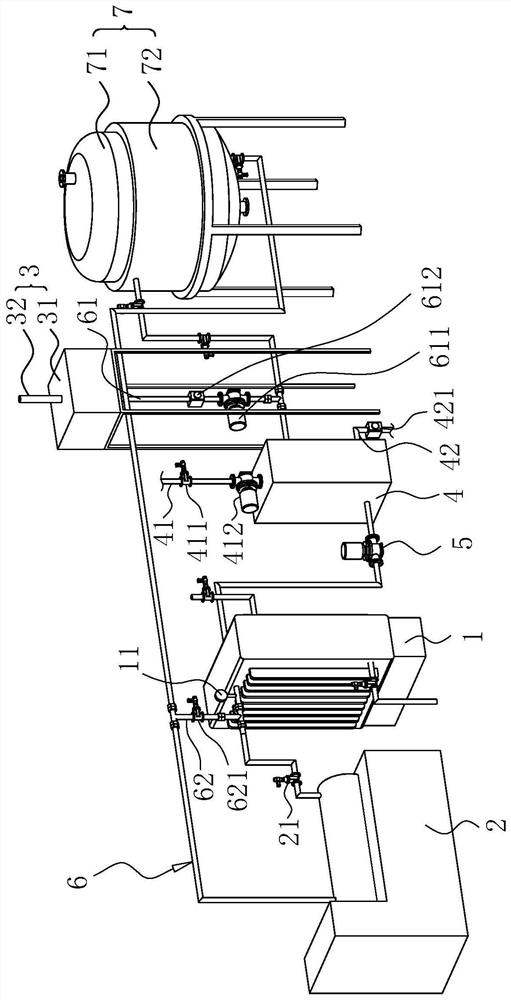

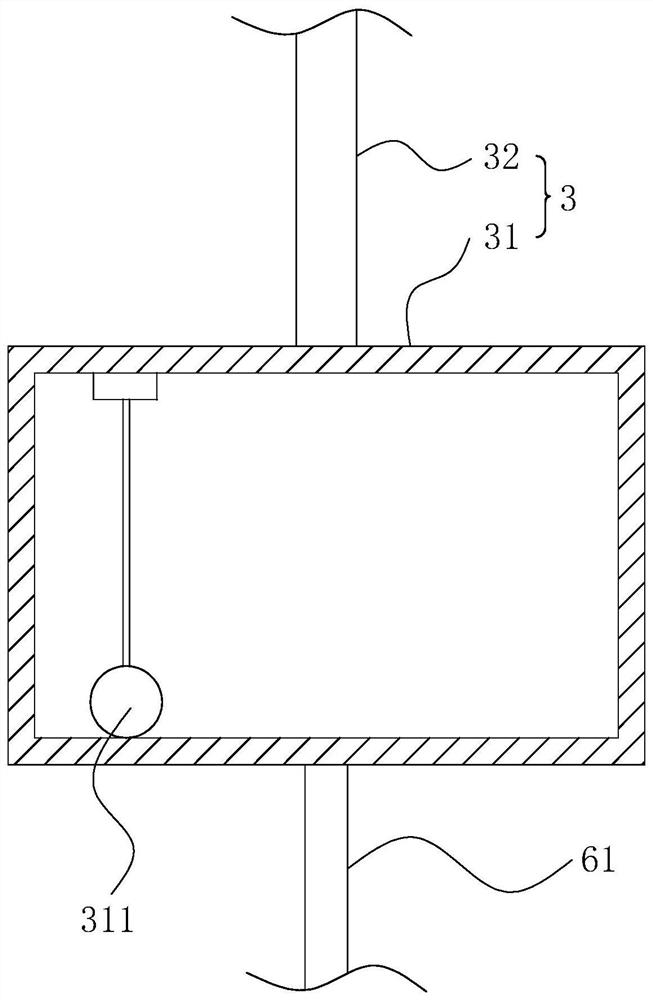

[0034] The following is attached Figure 1-2 The application is described in further detail.

[0035] The reaction kettle is a common reaction device 7 in the field of medicine and chemical industry, including a reaction kettle body 71 and a reaction kettle jacket 72. The reaction kettle jacket 72 is set on the outside of the reaction kettle body 71, and the inside of the reaction kettle jacket 72 is arranged along the circumference of the reaction kettle. There is a temperature control pipeline, the liquid inlet of the temperature control pipeline is arranged at the bottom of the reaction kettle jacket 72, and extends out of the reaction kettle jacket 72, and the liquid outlet of the temperature control pipeline is arranged at the top of the reaction kettle jacket 72, And stretch out reactor jacket 72 and set. When in use, by connecting the temperature control pipeline with the heating system and the cooling system, the heating medium or cooling medium is delivered to the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com