Energy-saving industrial cold and hot integrated water chilling unit

An integrated technology for water chillers, applied in the direction of refrigerators, refrigeration components, mechanical equipment, etc., can solve the problems of large storage space, low refrigerant content, and cost, so as to improve efficiency, reduce use time, increase The effect of large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

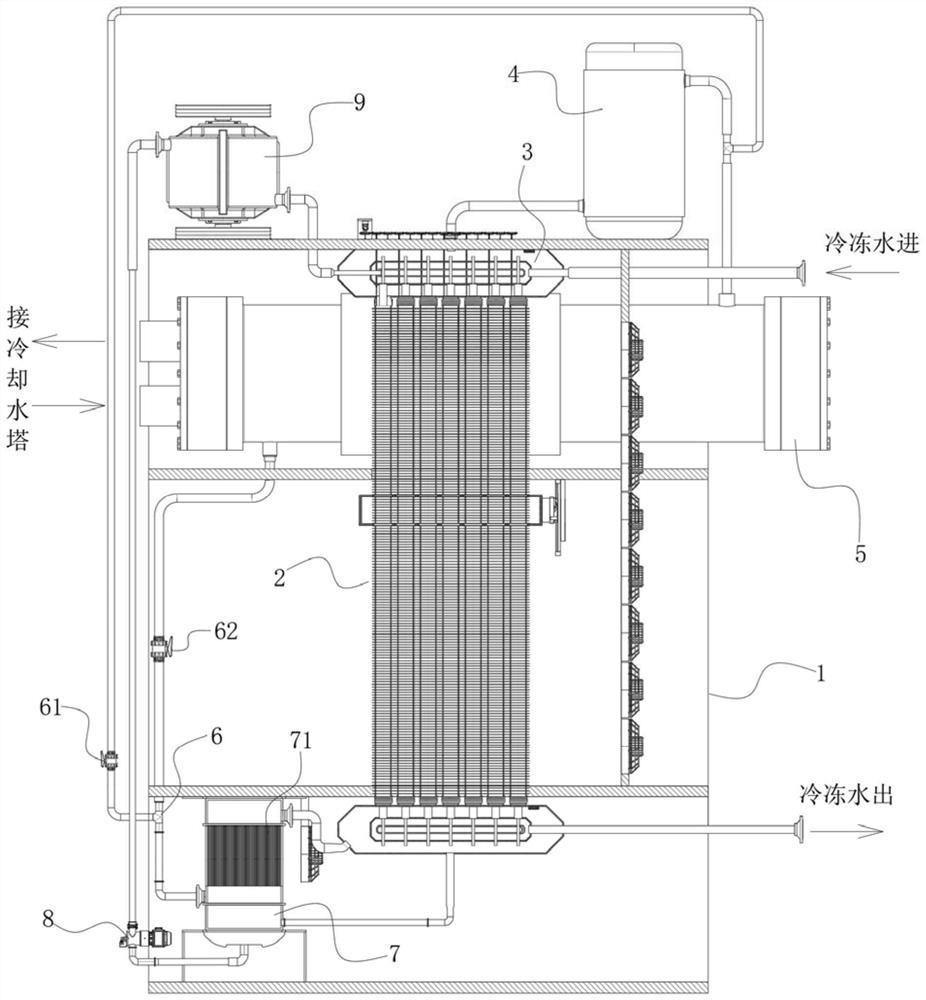

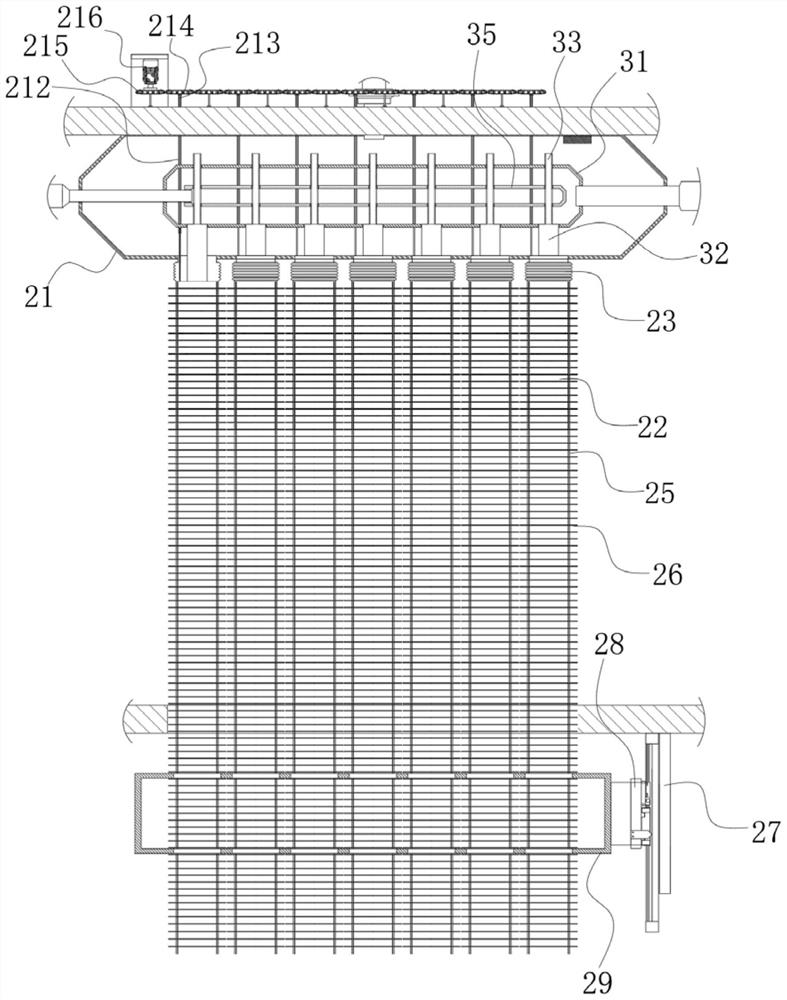

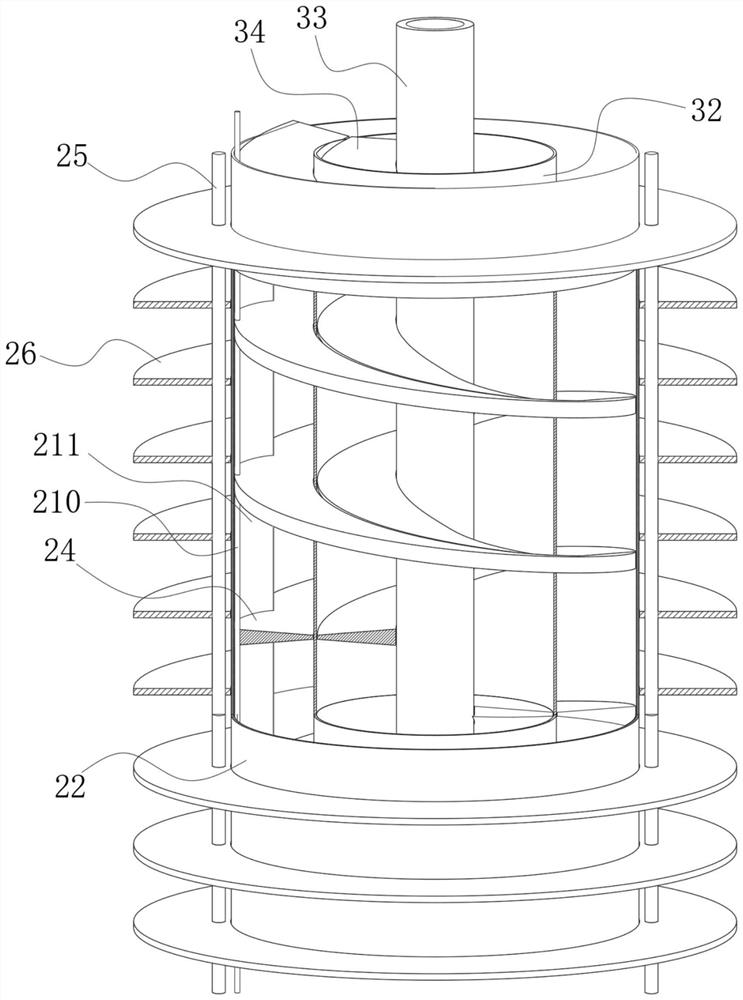

[0033] refer to Figure 1-5 , the present invention provides a technical solution: an energy-saving industrial cooling and heating integrated chiller, which includes a fixed plate frame 1, a flow control box 7 is installed on the bottom of the fixed plate 1, and a horizontally arranged condenser is installed on the top. Regulator tank 9 and compressor 4 are installed on the upper part of device 5, the top end, and outer drainage shell 2 arranged longitudinally is installed in the middle of the fixed plate frame, and inner diversion assembly 3 is embedded inside the outer drainage shell 2, and the The input end and the output end of the compressor 4 are respectively connected to the upper output end of the external drainage shell 2 and the upper right input end of the condenser 5, and the lower left output end of the condenser 5 is connected to the upper port of the three-communication 6 pipe, and is controlled by the The valve two 62 is regulated, and the output end of the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com