Aqueous exterior wall coating material with high solid content and low viscosity

An exterior wall coating, high solid content technology, applied in the direction of coating, can solve the problems of large labor cost and time increase, multi-manpower and time, long construction procedure, etc., achieve good environmental protection effect, high stability effect, easy construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] This kind of water-based high-solid low-viscosity exterior wall coating mainly includes: deionized water: 2%, thickener PUR40: 0.3%, ammonia water: 0.2%, water-based high-solid styrene-acrylic emulsion: 15%, Dispersant: 1.5%, water-based high solid content elastic acrylic emulsion: 25%, wetting agent: 0.5%, kaolin and nano high opacity polymer: 19%, rutile titanium dioxide: 35%, defoamer: 0.7% With coalescent: 0.8%. The defoamer in the above composition is SN-399 defoamer, and the film-forming aid is TEXANOL solvent.

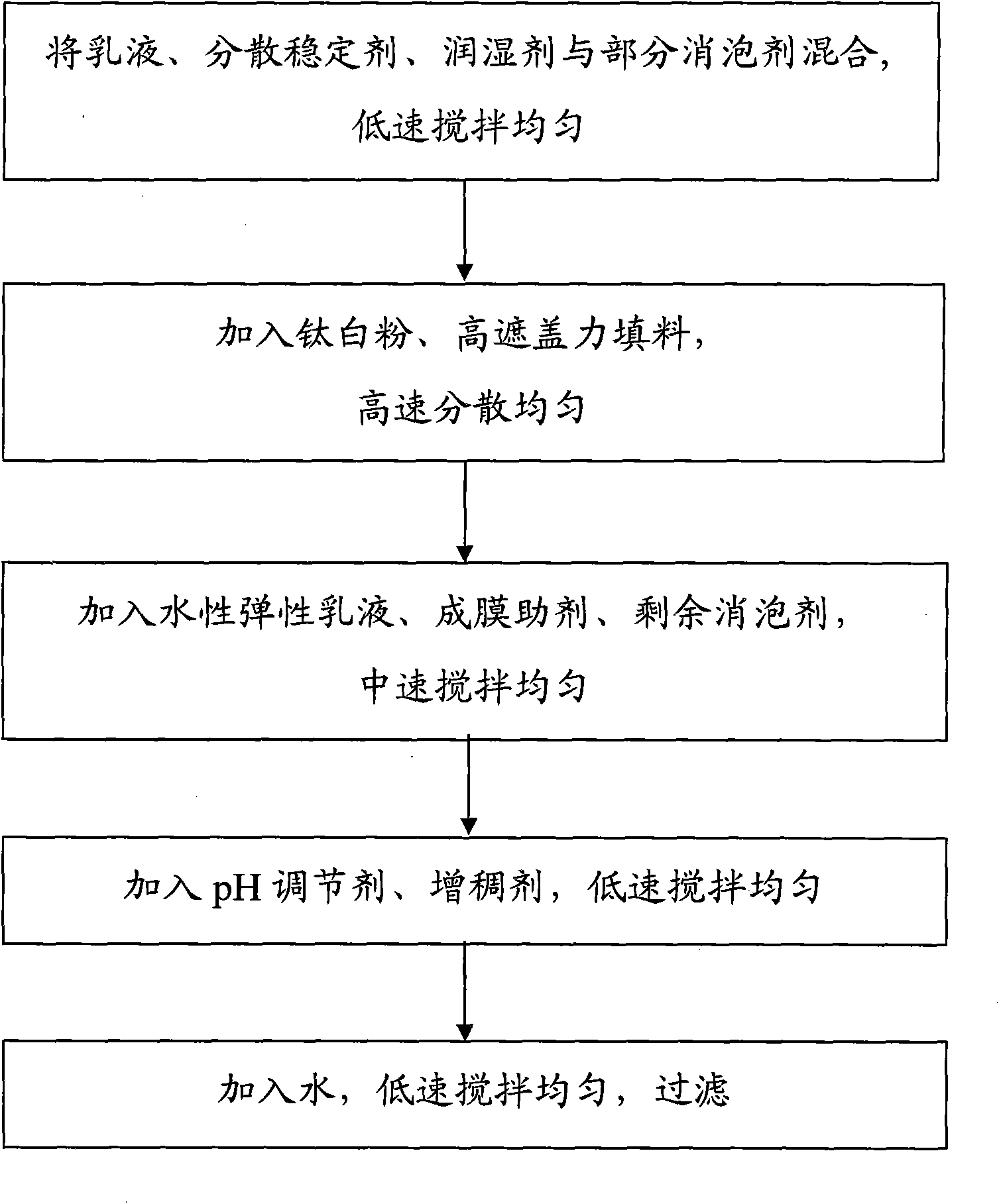

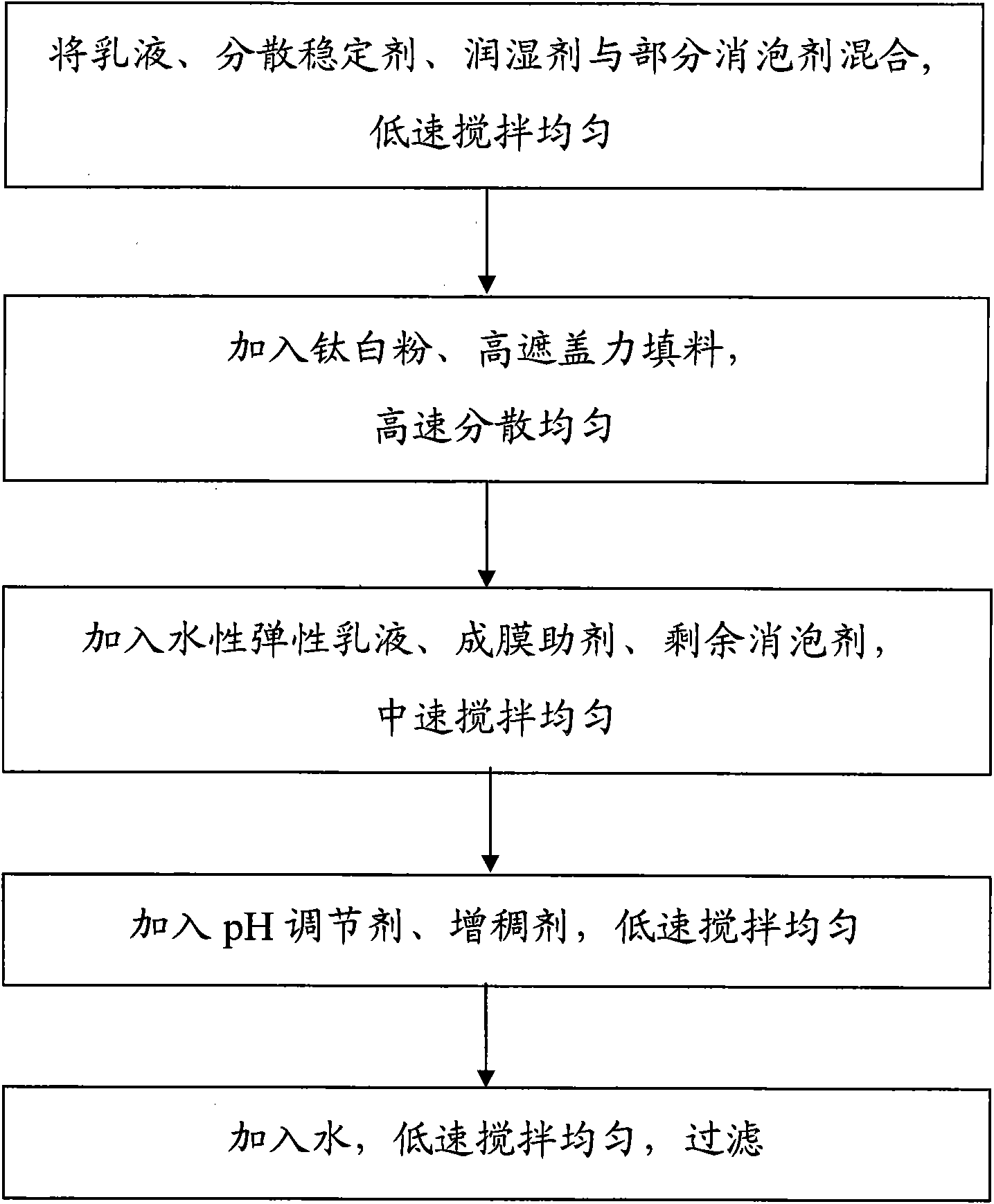

[0069] The above composition according to figure 1 The process shown in the manufacturing process mainly includes the following steps:

[0070] Step a: Weigh the raw materials according to the weight ratio of the above composition, add 15% high-solid styrene-acrylic emulsion, 1.5% dispersant, 0.5% wetting agent and 0.3% defoamer in sequence, stir at low speed for 5-10 minutes to fully mix uniform;

Embodiment 2

[0080] The difference between Example 2 and Example 1 is that the weight ratio of each component is changed. This kind of water-based high-solid low-viscosity exterior wall paint mainly includes: deionized water: 2.0%, thickener PUR40: 0.3%, ammonia water: 0.2%, water-based high-solid styrene-acrylic emulsion: 25%, dispersant: 1.5%, water-based high-solid elastic acrylic emulsion: 16%, wetting agent: 0.5%, kaolin and nano high opacity Force polymer: 24%, rutile titanium dioxide: 29%, defoamer: 0.7% and film-forming aid: 0.8%. The defoamer described in the above composition is SN-399 defoamer, and the film-forming aid is TEXANOL solvent

[0081] The above composition according to figure 1 The technological process shown is prepared, and it mainly comprises the following steps:

[0082] Step f: Weigh the raw materials according to the weight ratio of the above composition, add 25% of water-based styrene-acrylic emulsion, 1.5% of dispersant, 0.5% of wetting agent and 0.3% of de...

Embodiment 3

[0091] The difference between Example 3 and Example 1 and Example 2 is that the weight ratio of each component changes. This kind of water-based high-solid low-viscosity exterior wall paint mainly includes: deionized water: 2.0% , thickener PUR40: 0.3%, ammonia water: 0.2%, water-based high-solid styrene-acrylic emulsion: 20%, dispersant: 1.5%, water-based high-solid elastic acrylic emulsion: 21%, wetting agent: 0.5%, kaolin And nano-high hiding power polymer: 21%, rutile titanium dioxide: 32%, defoamer: 0.7% and film-forming aid: 0.8%. The defoamer described in the above composition is SN-399 defoamer, and the film-forming aid is TEXANOL solvent

[0092] The above composition according to figure 1 The technological process shown is prepared, and it mainly comprises the following steps:

[0093] Step k: Weigh the raw materials according to the weight ratio of the above composition, add 20% of styrene-acrylic emulsion, 1.5% of dispersant, 0.5% of wetting agent and 0.3% of def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com