A kind of waterborne epoxy modified acrylic resin and preparation method thereof

An acrylic resin and water-based epoxy technology, applied in the field of water-based coatings, can solve the problem that water-based resins are difficult to meet the performance indicators of automobile axles, and achieve the effects of excellent hardness and adhesion, reducing environmental pollution, and reducing environmental and human injury.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

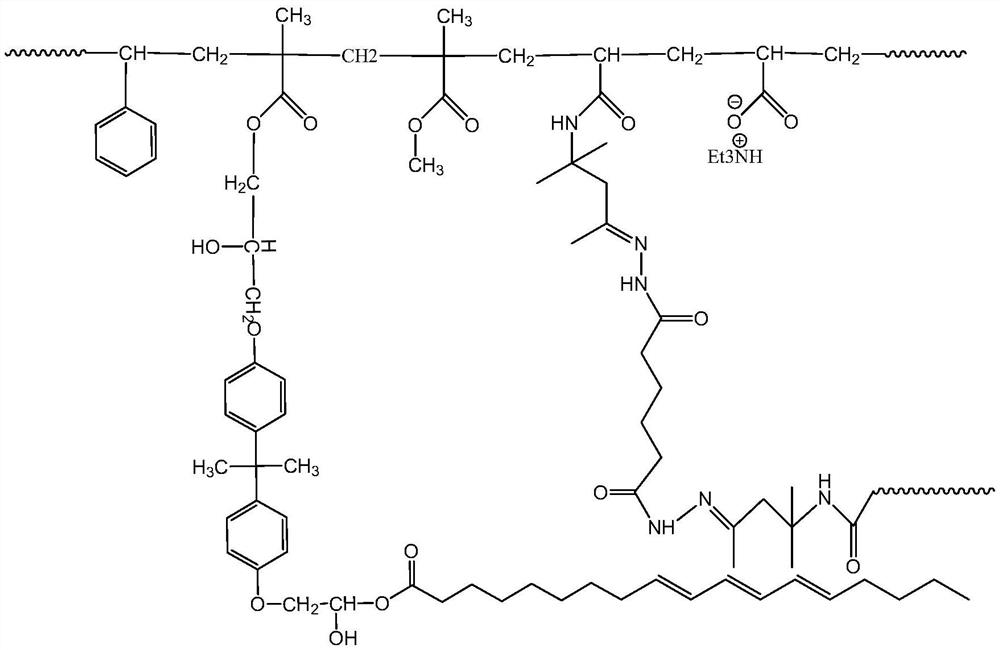

[0036] The preparation of waterborne epoxy modified acrylic resin, the steps are as follows:

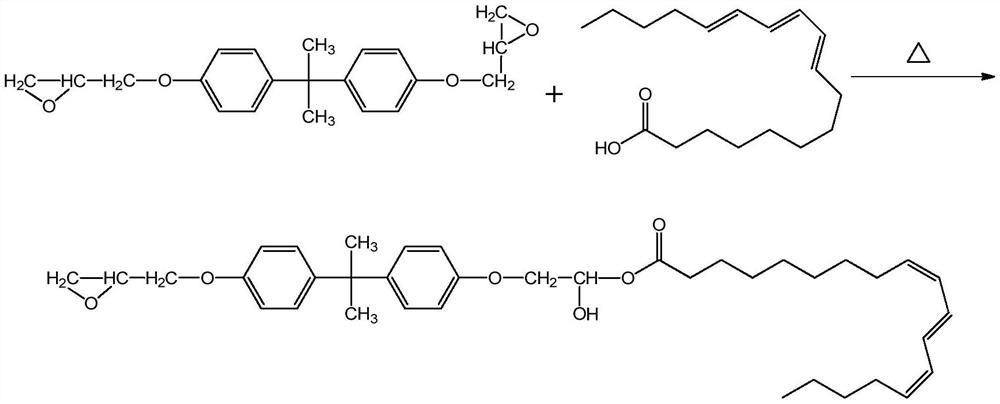

[0037] (1) Preparation of epoxy ester resin: under nitrogen protection, 15 parts of oleic acid, 20 parts of tungoleic acid, 10 parts of soybean oleic acid, 20 parts of epoxy resin, 0.02 part of zinc oxide, 7 parts of butanone, 8 parts Ethylene glycol butyl ether was added into a four-necked reaction flask equipped with a stirrer, an air guide tube, a thermometer, and a condenser tube. Under the protection of nitrogen, the temperature was raised to 80° C. for 2 hours, and then the temperature was raised to 140° C. for 2 hours until the acid value of the epoxy ester resin was 3 mgKOH / g to obtain an epoxy ester resin.

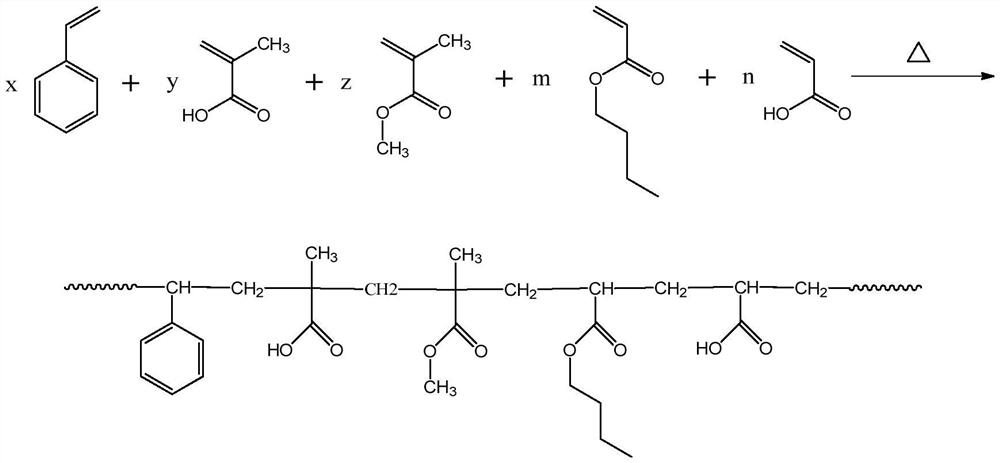

[0038] (2) Preparation of hydrophilic acrylic resin: under nitrogen protection, add 25 parts of methyl methacrylate, 5 parts of diacetone acrylamide, 30 parts of styrene, 10 parts of acrylic acid, and 5 parts of acrylamide to the , air duct, thermometer, and condenser t...

Embodiment 2

[0041] The preparation of waterborne epoxy modified acrylic resin, the steps are as follows:

[0042] (1) Under the protection of nitrogen, 10 parts of oleic acid, 10 parts of oleic acid, 12 parts of linoleic acid, 25 parts of epoxy resin, 0.05 parts of triphenylphosphine, and 10 parts of butyl acetate are added to the mixture equipped with a stirrer, In the four-necked reaction flask with air guide tube, thermometer and condenser tube. Under the protection of nitrogen, the temperature was raised to 90°C for 1 hour, and then the temperature was raised to 120°C for 3 hours until the acid value of the epoxy ester resin was 6 mgKOH / g to obtain an epoxy ester resin.

[0043] (2) Under the protection of nitrogen, add 15 parts of butyl methacrylate, 4 parts of diacetone acrylamide, 25 parts of styrene, and 12 parts of methacrylic acid to the four parts equipped with stirrer, air guide tube, thermometer and condenser tube. In a reaction bottle, heat while stirring, raise the tempera...

Embodiment 3

[0046] The preparation of waterborne epoxy modified acrylic resin, the steps are as follows:

[0047] (1) Under the protection of nitrogen, 20 parts of ricinoleic acid, 25 parts of oleic acid, 30 parts of epoxy resin, 0.3 parts of cobalt chloride, and 20 parts of ethylene glycol butyl ether are added to the mixture equipped with agitator, air duct and thermometer. , into the four-necked reaction flask of the condenser tube. Under the protection of nitrogen, the temperature was raised to 95° C. for 1 h, and then the temperature was raised to 120° C. for 3 h until the acid value of the epoxy ester resin was 8 mgKOH / g to obtain an epoxy ester resin.

[0048] (2) Under nitrogen protection, add 20 parts of butyl methacrylate, 5 parts of diacetone acrylamide, 20 parts of butyl acrylate, 12 parts of lauryl acrylate, and 10 parts of acrylic acid to the , into a four-necked reaction flask with a condensing tube, heat while stirring, raise the temperature to 110°C, slowly add dropwise ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com