A high-solids, low-viscosity, cooking-resistant water-based film-coated adhesive and preparation method thereof

A low-viscosity, retort-resistant technology, applied in the field of film-coated adhesives, can solve the problems of poor wettability of non-polar films, difficulties in meeting the requirements of composite flexible packaging, poor water resistance, heat resistance and mechanical properties, and achieve Enhance mechanical properties and retort resistance, overcome the effects of poor retort resistance and retort mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

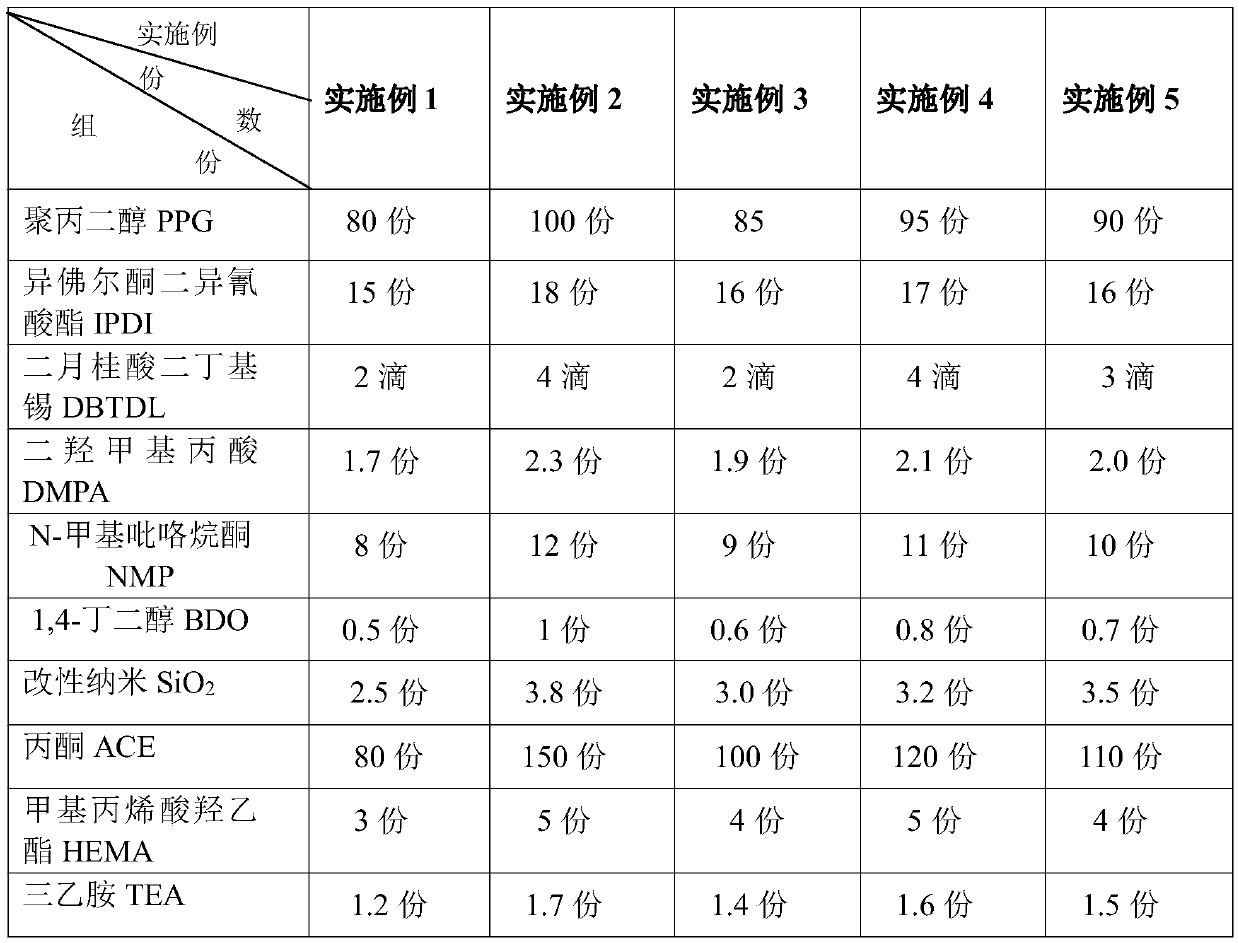

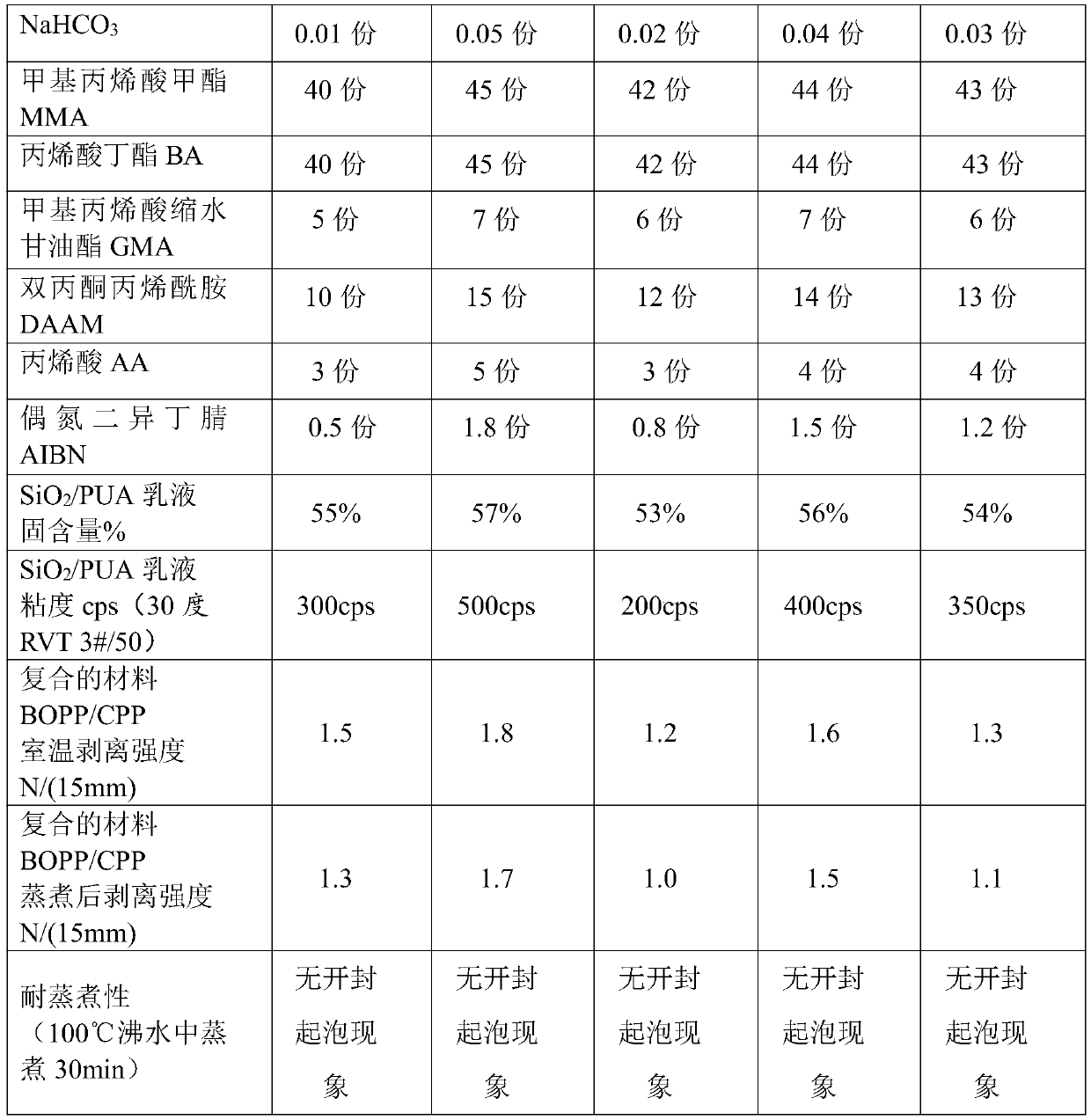

Examples

Embodiment

[0029] (1) Nano SiO 2 Organic modification: 3 to 5 parts of nano-SiO 2 Bake and activate in an oven at 120°C for 2 to 4 hours, add 4 to 10 parts of γ-aminopropyltriethoxysilane KH-550 dropwise after cooling down, and ultrasonically disperse in 5 to 7 parts of N-formazan dehydrated by molecular sieves After 20-40min in the base pyrrolidone solvent, in N 2 Heating to 70-75°C under heat preservation and reflux stirring, suction filtering the reacted suspension to obtain a filter cake, washing the filter cake three times with absolute ethanol, removing the residual silane coupling agent, and putting the filter cake in Dry in an oven at 100-150°C for 1-2 hours to obtain modified nano-SiO 2 .

[0030] (2) Synthesis of polymerizable polyurethane-acrylate emulsion containing double bonds:

[0031] a. Dehydrate 80-100 parts of polypropylene glycol PPG or polytetrahydrofuran diol PTHF at 100-150°C and a vacuum of 0.1MPa for 1-4 hours in a high-temperature kettle, then cool down to 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com