Method for preparing high-purity copper oxide by adopting acidic etching waste liquor

A technology of acidic etching waste liquid and etching waste liquid, applied in chemical instruments and methods, copper oxide/copper hydroxide, water/sewage multi-stage treatment, etc., can solve problems such as uneven temperature rise, increased cost, and difficult heat conduction. Achieve good environmental protection effect and achieve zero emission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

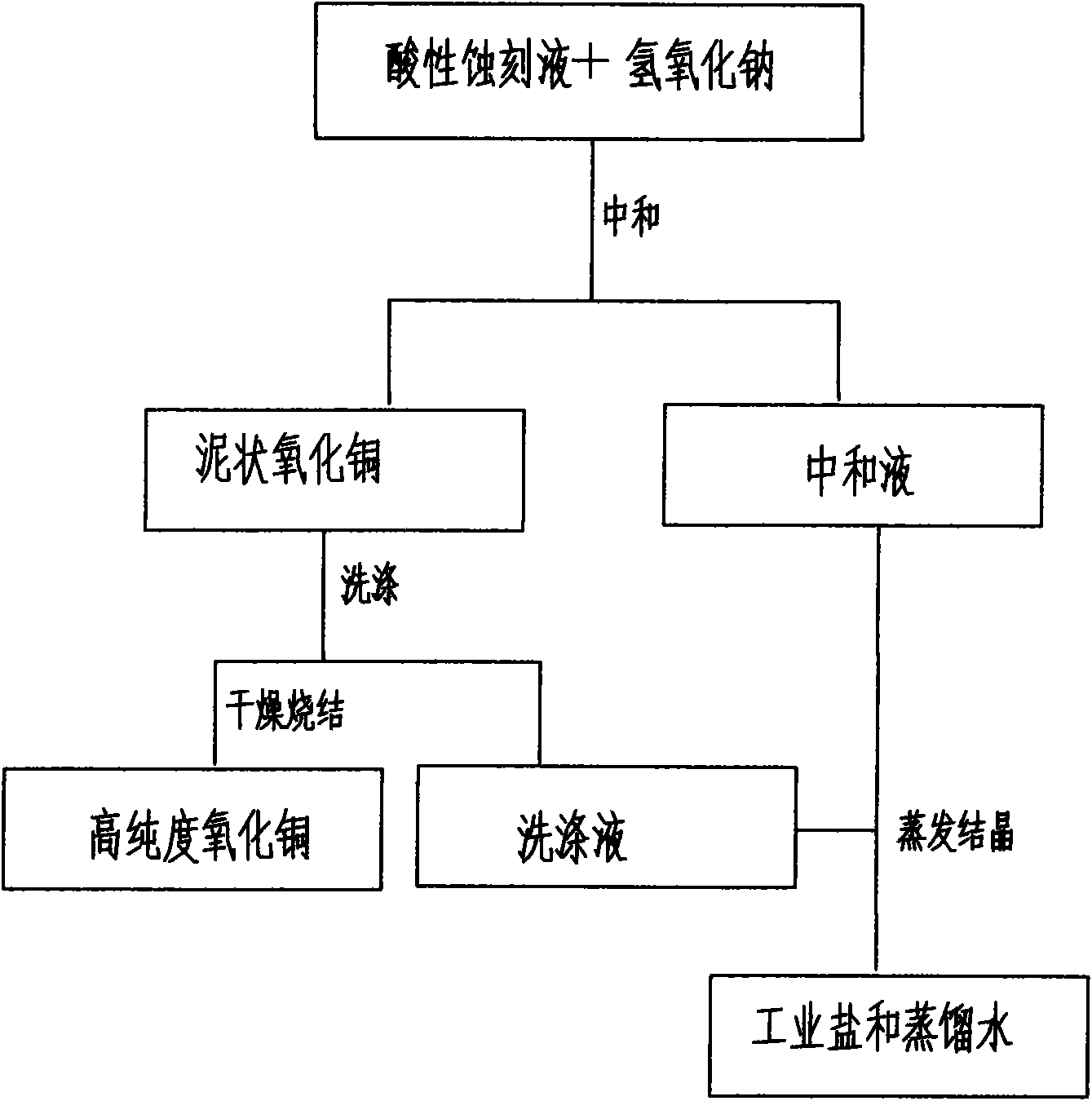

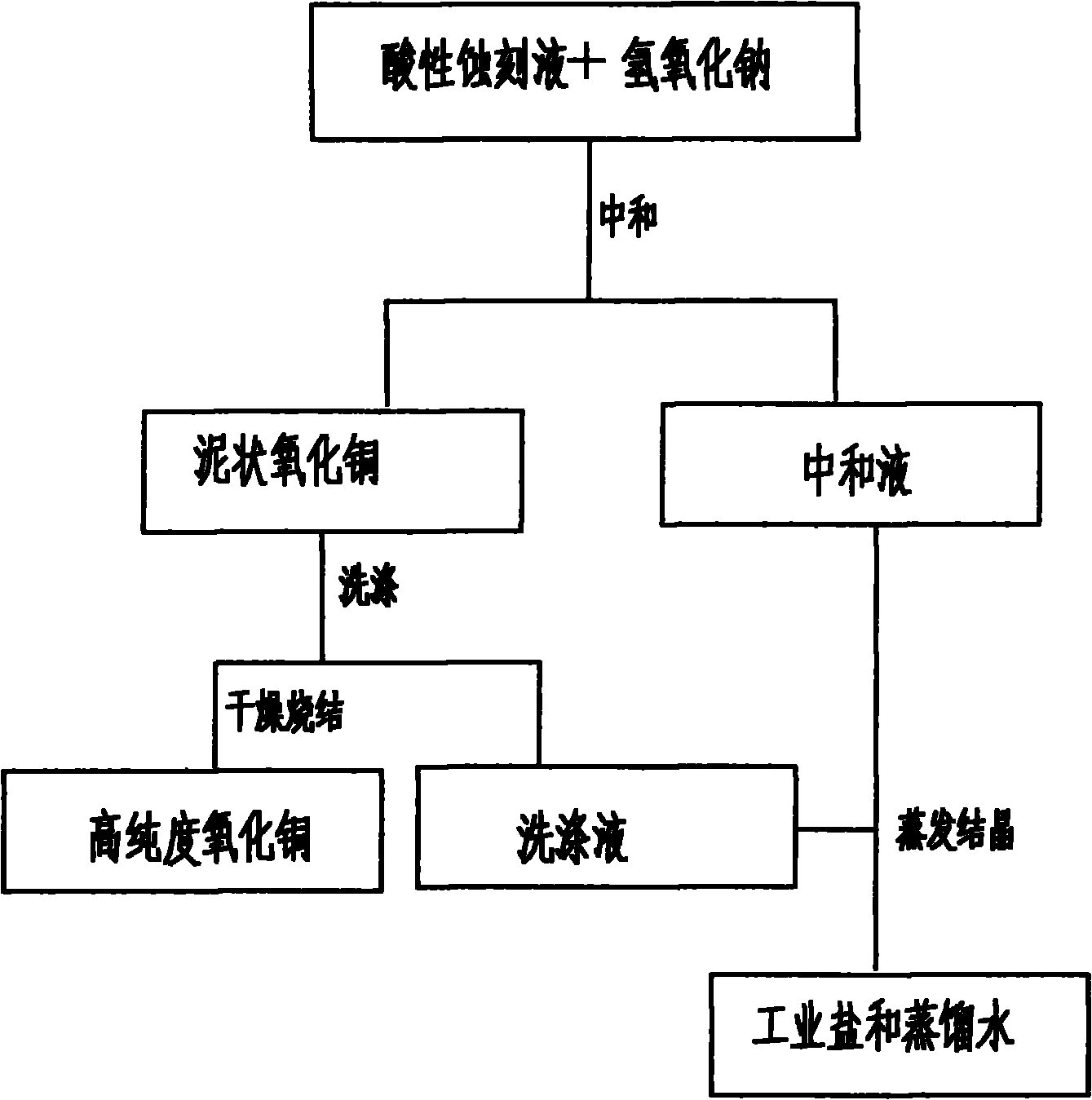

[0018] The preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings by taking the acid copper chloride etching waste solution (its composition: copper 145g / L, hydrochloric acid 12%) as an example.

[0019] step:

[0020] 1) Neutralization: The acidic copper chloride etching waste liquid of the printed board manufacturer is filtered to remove insoluble solid impurities, and then injected into 30-35% (weight percent) sodium hydroxide solution at an initial temperature of 40-60 ° C, hydrogen The sodium oxide solution is continuously stirred, and the end point pH is ≥ 8.0. When the acid solution is injected, copper hydroxide is produced, and immediately dehydrated at a temperature of 40-60 ° C to form copper oxide in a muddy state, and the reaction process has been maintained at a pH ≥ 8.0. The muddy copper oxide is located in the lower layer, and the upper layer is the neutralizing solution after the reaction. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com