Ultraviolet light curing oil polish and preparation thereof

A technology of ultraviolet light and varnish, applied in the direction of coating, etc., can solve the problems of poor adhesion, high cost, time-consuming, etc., and achieve the effect of not easy to leak, excellent adhesion, and strong wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

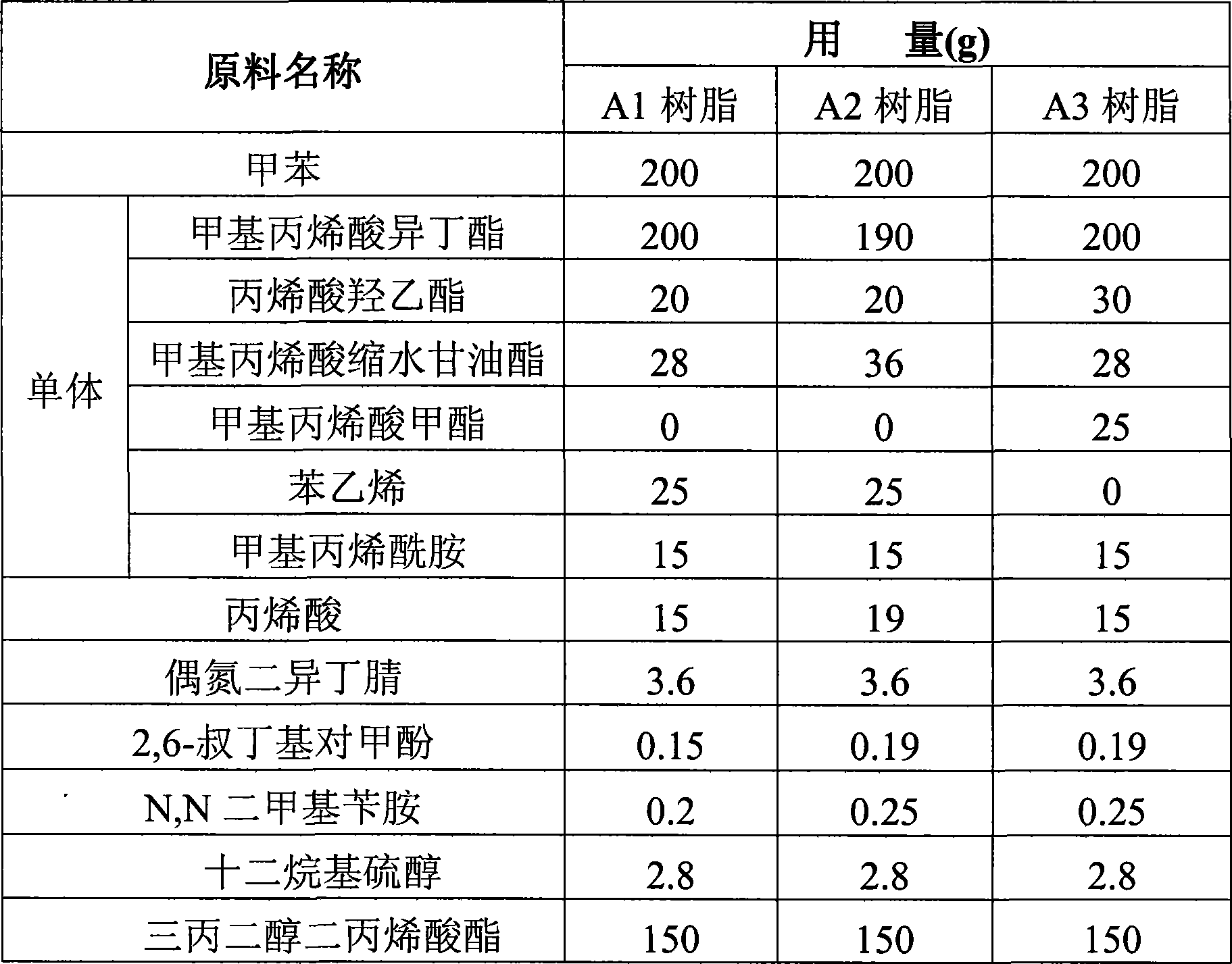

[0018] 1. Preparation of active oligomers:

[0019] Add 150g of toluene to a 1000ml four-neck flask equipped with a stirrer, condenser, thermometer and dropping funnel, raise the temperature to 85±2°C, mix the monomers of each resin in advance, add 1.3g of azobisisobutyl Nitrile and 2.8g of dodecyl mercaptan are completely dissolved to make a monomer mixture, add 1 / 6 of the monomer mixture to the four-neck flask, stir, keep warm for 1 hour, add the remaining monomer dropwise, and finish dropping in 2.5-3 hours , keep warm for 2 hours, heat up to 110°C, add dropwise 2.3g of azobisisobutyronitrile pre-dissolved with 50G, drop it in 1.5h, keep warm for 3h, add 2,6-tert-butyl p-cresol, stir well and then add acrylic acid React with N,N dimethylbenzylamine at 110-115°C until the acid value is less than 10mgKOH / g, add 150g of tripropylene glycol diacrylate, cool down to 85°C, and keep the vacuum degree above -0.097 and the temperature at 80 Toluene was distilled under reduced press...

Embodiment 2

[0023] 1. The preparation method of active oligomer is as embodiment 1, but replaces toluene with acetone, ether or any organic solvent.

[0024] 2. The preparation of UV-curable varnish is as in Example 1, but A2 is used instead of A1.

Embodiment 3

[0026] 1. The preparation method of active oligomer is as embodiment 1, but replaces toluene with acetone, ether or any organic solvent.

[0027] 2. The preparation of UV-curable varnish is as in Example 1, but A3 is used instead of A1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com