Preparation method of graphene heat-conducting film and product obtained by preparation method

A graphene film and graphene technology, applied in the direction of graphene, chemical instruments and methods, modification through conduction and heat transfer, etc., can solve the problems of poor film-forming property of graphene, achieve good film-forming property, strong thermal conductivity, The effect of fast delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

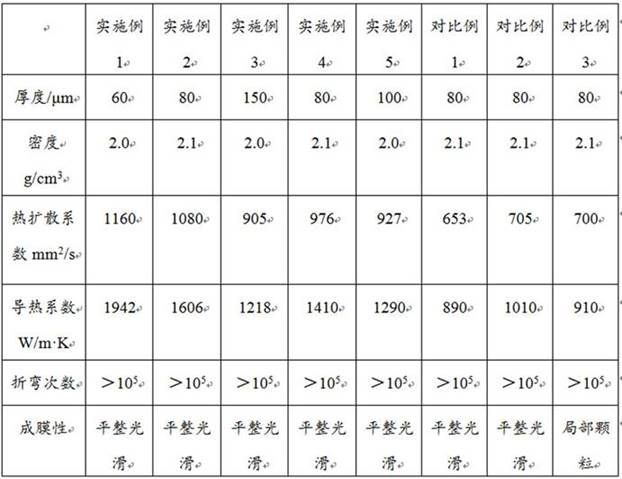

Examples

preparation example Construction

[0026] The invention provides a kind of preparation method of graphene heat conduction film, comprises the steps:

[0027] 1) Mixing the aqueous solution of graphene oxide and the foaming agent, vacuum defoaming and filtering the obtained mixed solution in turn to obtain the graphene oxide dispersion;

[0028] 2) Coating and drying the graphene oxide dispersion in step 1) to obtain a dried graphene oxide film;

[0029] 3) foaming the dried graphene oxide film in step 2) to obtain a foamed graphene oxide film;

[0030] 4) Place the foamed graphene oxide film in the step 3) in the interlayer of graphite sheets, and then perform high temperature treatment, vacuum treatment, air replacement treatment and hot pressing treatment in order to obtain a graphene heat conducting film;

[0031] The air replacement treatment is to introduce high thermal conductivity gas to replace the air in the pores of the heat conduction film with high thermal conductivity gas.

[0032] The present in...

Embodiment 1

[0043] S1. Put the graphene oxide aqueous solution (the mass concentration of graphene oxide is 0.5g / L, the sheet diameter is 10μm) and ammonium bicarbonate (the foaming agent is 2% of the mass of graphene oxide) in a high-speed shearing machine at 5000rpm Stir and disperse for 2 hours at a certain speed;

[0044] S2. Defoaming the mixed solution obtained in S1 for 20 minutes under a vacuum of 100 Pa, and then filtering it through a filter to obtain a graphene oxide dispersion;

[0045] S3. Coat the graphene oxide dispersion on the polytetrafluoroethylene PTFE membrane by a scraper coater, dry the base material coated with the graphene oxide slurry at 50°C, and dry the base material with the drying The graphene oxide film is separated to obtain a dry graphene oxide film;

[0046] S4, placing the dried graphene oxide film in a low-temperature box at 100° C. for low-temperature foaming for 120 minutes to obtain a foamed graphene oxide film;

[0047] S5. After cutting the foame...

Embodiment 2

[0051] S1. Put the graphene oxide aqueous solution (the mass concentration of graphene oxide is 1g / L, and the sheet diameter is 300μm) and ammonium carbonate (the foaming agent is 0.01% of the mass of graphene oxide) in a high-speed shearing machine at a speed of 5000rpm Stir and disperse for 1.5h;

[0052] S2. Defoaming the mixed solution obtained in S1 for 30 minutes under a vacuum of 100 Pa, and then filtering it through a filter to obtain a graphene oxide dispersion;

[0053] S3. Coat the graphene oxide dispersion on the methyl plate by a scraper coater, dry the substrate material coated with the graphene oxide slurry at 100°C, and combine the above substrate material with the dried graphite oxide Graphene film is separated to obtain dry graphene oxide;

[0054] S4, placing the dried graphene oxide film in a low-temperature box at 300° C. for low-temperature foaming for 10 minutes to obtain a foamed graphene oxide film;

[0055] S5. After cutting the foamed graphene oxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com