Bolt tightening machine capable of highly automatically searching, straightening and filling

A technology for tightening machines and bolts, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as difficult operation of bolts, and achieve the effects of high automation, high safety factor, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings.

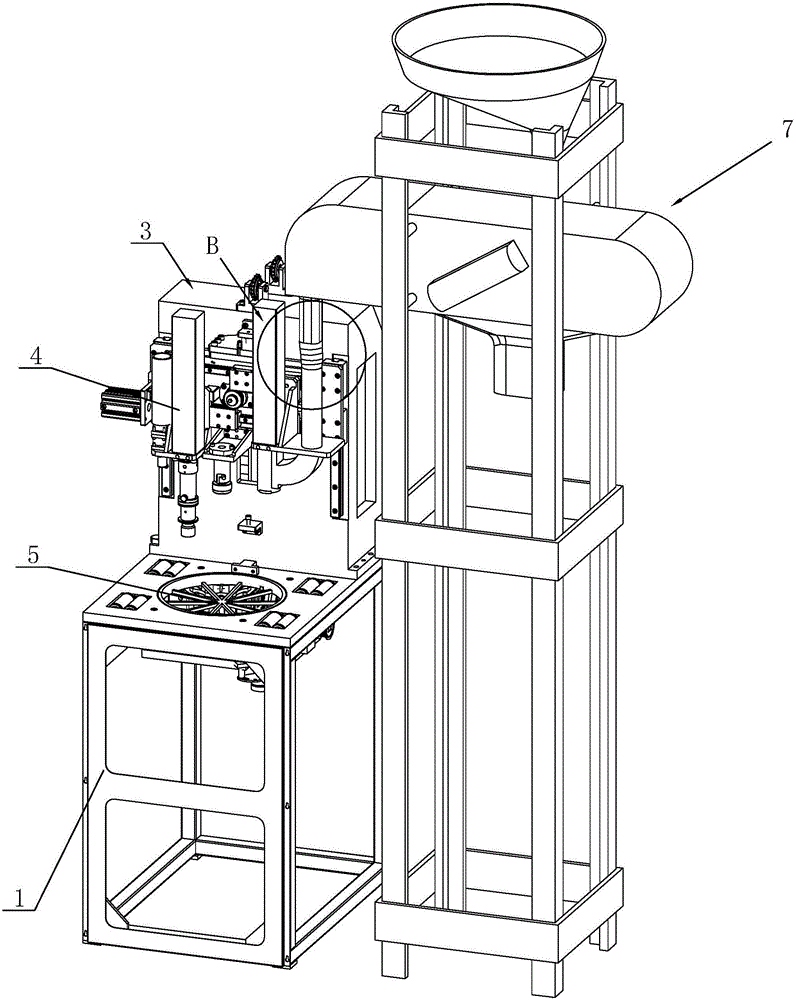

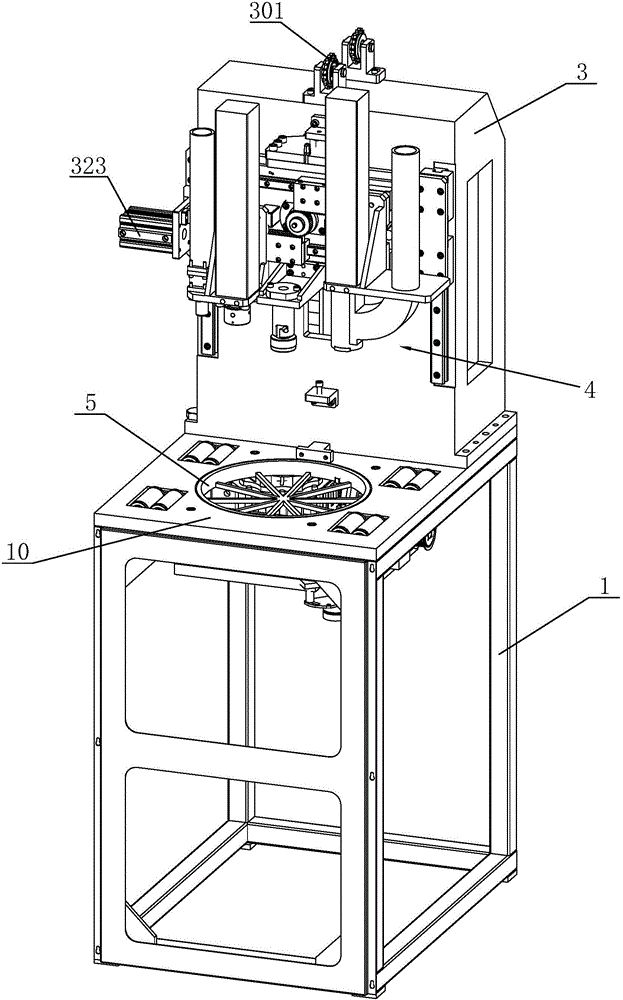

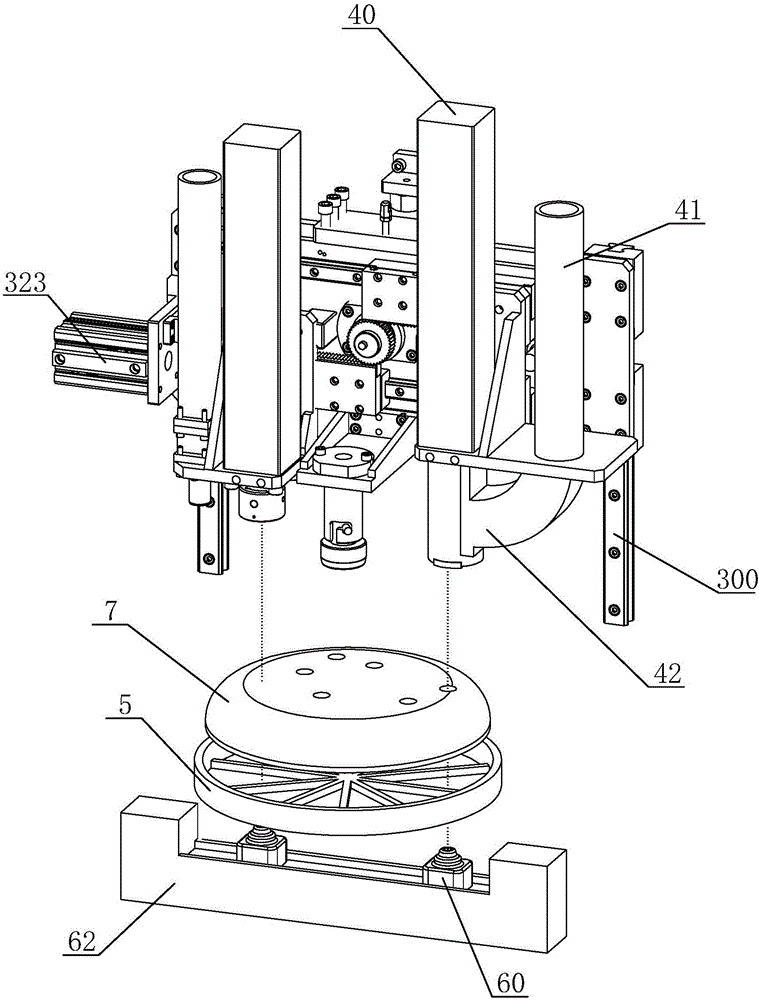

[0052] like Figures 1 to 18 Shown is a bolt tightening machine with high automatic positioning and filling, which consists of two parts: bolt assembly device and straightening device.

[0053] Among them, the straightening device such as Figure 13 to Figure 17 As shown, it is connected with the filling device, including a storage hopper 71, a valve 72, a conveyor belt 73, a casing 76 and a discharge pipe 74 for delivering bolts to the filling device. The top of the casing 76 is provided with a storage hopper 71, and the storage hopper 71 is provided with a feed pipe 711 for feeding the conveyor belt. Valve 72 is installed on the feed pipeline 711 side; Said conveyer belt 73 is located at the inside of shell 76, and conveyer belt 73 comprises front end, and discharge pipe 74 is positioned at the below of conveyer belt front end 73a, and discharge pipe 74 connects fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com