Macromolecular oriented film and preparation method and application thereof

A technology of oriented film and polymer, applied in the field of polymer oriented film and its preparation and application, to achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the polymer oriented film of the present invention comprises: (1) the step of forming the first polymer oriented film; (2) the step of forming the polymer oriented film.

[0032] In the step (1) of the present invention, the first polymer oriented film is prepared by a melt stretching method, and the first polymer oriented film is attached to the substrate. The melt stretching method can be carried out using devices and processes known in the art, such as the devices and processes disclosed in CN103407179A or CN103451698A, the entire contents of which are incorporated herein by reference. The melt-stretching method can conveniently obtain a polymer oriented film with a thickness of nanometer scale.

[0033]The first polymer is dissolved in an organic solvent to obtain a solution with a concentration of the first polymer of 0.1-5 wt%, such as 1-3 wt%. Preheat the hot stage to 110-235°C, preferably 130-200°C, more preferably 135-165°C, then pour...

Embodiment 1

[0064] High-density polyethylene HDPE was dissolved in xylene to obtain a solution with a polyethylene concentration of 1 wt%. Preheat the hot stage to 135°C, then pour the above solution onto the glass plate placed on the preheated hot stage, and coat it uniformly to form a thin film. After the solvent is heated and volatilized completely, adjust the rotational speed of the rotating roller to 120rpm, control the rapid contact between the rotating roller and the surface of the film, and separate and lift it to a certain height. At this time, a molten stretched oriented polyethylene film A is formed between the rotating roller and the glass plate . Remove the polyethylene film A by attaching to the substrate.

[0065] The above-mentioned polyethylene film was used as the base of the epigenetic crystal, and it was attached on the silicon wafer. Dissolve poly-1,4-butylene adipate and polycaprolactone (1:1 by weight) in chloroform to obtain a blend solution with a polymer concen...

Embodiment 2

[0070] The above-mentioned polyethylene film A was used as the base of the epigenetic crystal, and it was attached on the silicon wafer. Poly(adipate-co-succinate)butylene glycol ester and polycaprolactone (1:1 weight ratio) were dissolved in chloroform to obtain a blend solution with a polymer concentration of 1 wt%. Set the speed of the homogenizer to 3000rpm, use a pipette gun to evenly throw the blend solution on the surface of the polyethylene film to form a blend film, place it on a hot stage at 80°C for 5 minutes, and then transfer it to 35°C. ℃ heat treatment on a hot table for 24 hours to obtain a polymer oriented film (polyethylene film+blend film).

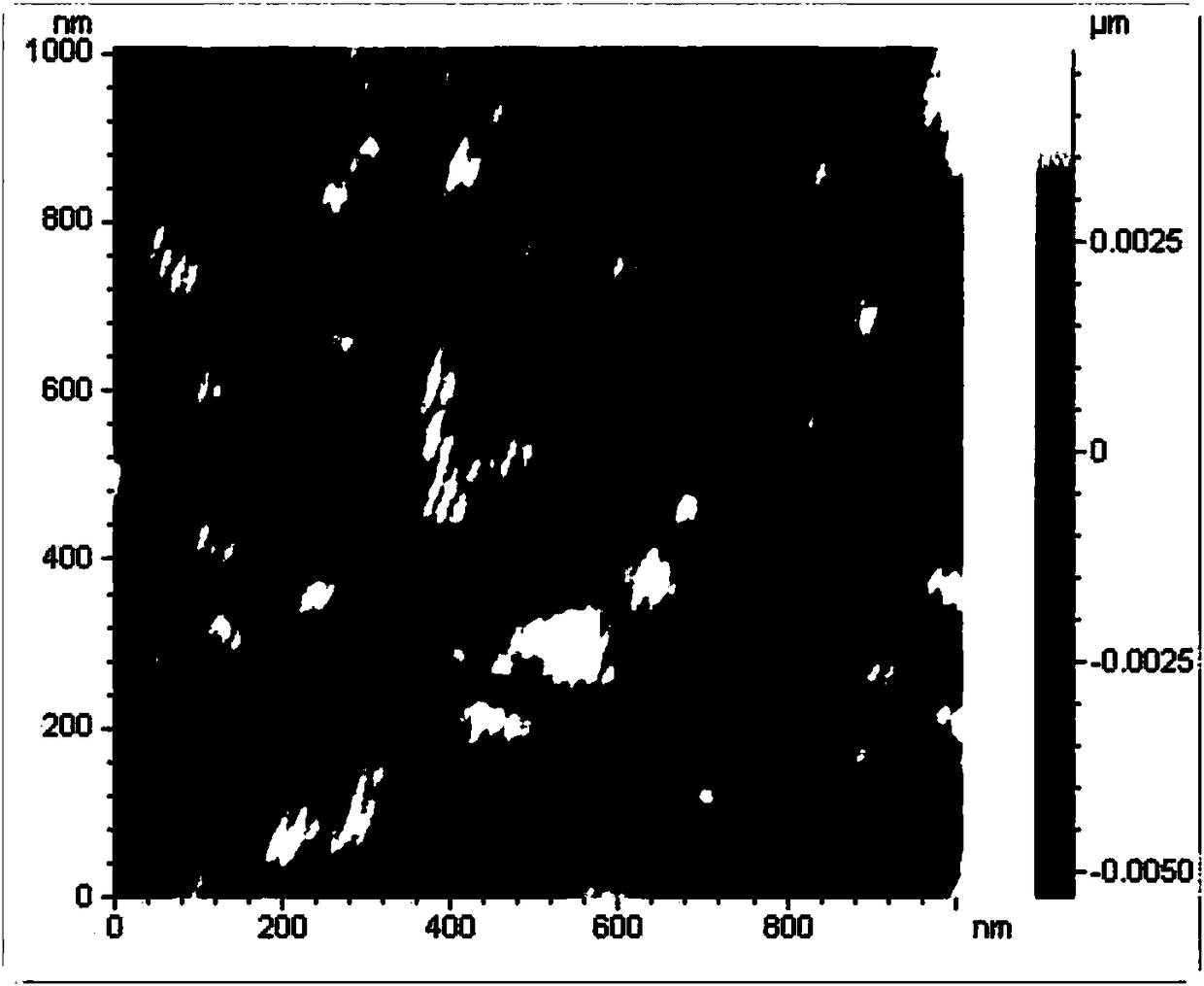

[0071] The polymer oriented film was observed with a polarizing microscope, and a corresponding extinction phenomenon was observed through the comparison of light and dark changes, which proved that the obtained polymer oriented film had an oriented structure. The polymer oriented film was tested by an atomic force mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com