Surface enhanced raman scattering substrate and preparation method thereof

A surface-enhanced Raman and substrate technology, applied in the field of spectral detection, can solve the problems of high processing cost, poor controllability and poor assembly controllability, and achieve the effect of reducing the area, reducing the difficulty of the process, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

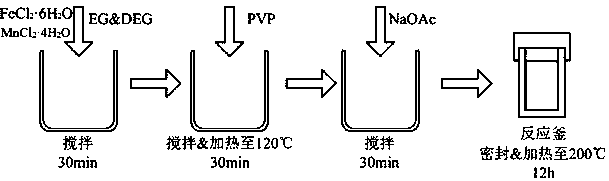

[0041] Please refer to Figure 7 , Figure 8 , the invention provides a method for preparing a surface-enhanced Raman scattering substrate, comprising the following steps:

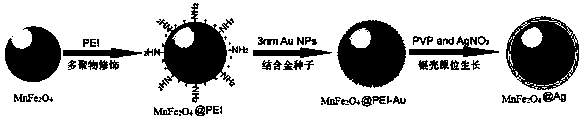

[0042] Step S1, preparing metal magnetic beads. The specific structure of the metal magnetic beads is a magnetic sphere inner core and a noble metal shell covering its outer surface; in a specific embodiment of the present invention, a chemical synthesis method is used to prepare magnetic ferromanganese Oxygen microspheres are used as the inner core of the magnetic sphere, and then a noble metal shell is coated on the outer core of the magnetic sphere to form a metal magnetic bead; the noble metal here refers to gold, silver, and copper.

[0043] Step S2, preparing a number of confinement pits distributed in an array in the preparation area on one side of the substrate body, the bottom surface of the confinement pits is planar; in a specific embodiment of the present invention, the substrate body is made ...

Embodiment 2

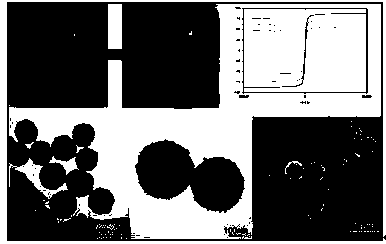

[0121] Please refer to Figure 9 , Figure 10 , the embodiment of the present invention also provides a surface-enhanced Raman scattering substrate, which decomposes a large-area SERS substrate into a plurality of small areas at designated positions, ensuring that the distribution of SERS hot spots in each small area is the same; it includes a substrate body 1 and A number of metal magnetic beads 2;

[0122] The base body 1 is in the shape of a sheet, one side of which is provided with a preparation area P;

[0123] The bottoms of several confinement pits 50 are flat bottoms (bottoms are flat), and all are located in the preparation area P, and several confinement pits 50 are distributed in an array; the depth of each confinement pit 50 along the confinement pit 50 is The direction is formed with at least one metal bead layer 60, see Figure 11 , each layer of metal magnetic beads 60 includes a plurality of metal magnetic beads 2 uniformly and closely arranged in the confin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com