3-3 type piezoelectric ceramic/cement piezoelectric composite material and preparation method thereof

A technology of piezoelectric composite materials and piezoelectric ceramics, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, material selection for piezoelectric devices or electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive Stretchable devices and other directions can solve problems such as cutting difficulty and achieve good durability, excellent piezoelectric performance, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

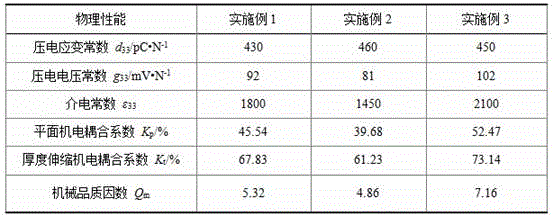

Embodiment 1

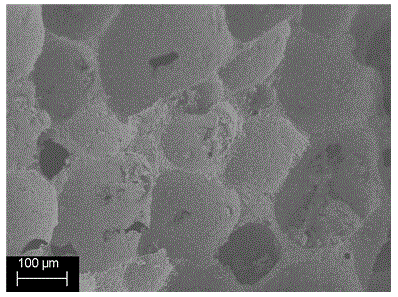

[0034] Dissolve 12.5wt% acrylamide monomer and 0.5wt% crosslinking agent methylenebisacrylamide in 87wt% water to make a premix; add lead zirconate titanate ceramic powder to 100m1 premix, ball mill After 12 hours, a lead zirconate titanate ceramic suspension with a solid phase volume fraction of 15% was prepared, that is, the volume of lead zirconate titanate accounted for 15% of the total volume of the slurry after adding the lead zirconate titanate ceramic powder. Add 100 μl of initiator ammonium persulfate solution (35wt%) and 0.5ml of foaming agent propionic acid into the suspension, and stir rapidly to foam. The ceramic foam is poured into the mold, and placed in a low-temperature constant temperature freezing tank at a temperature of -15°C for 20 hours to form. Immediately after the frozen body is taken out, it is placed in an electric drying oven at a temperature of 150°C, and the acrylamide monomer undergoes a curing reaction under the combined action of high temperat...

Embodiment 2

[0036]Dissolve 19.5wt% hydroxyethyl methacrylate monomer and 0.5wt% crosslinking agent methylenebisacrylamide in 80wt% water to make a premix; add niobium magnesium zirconium titanate to 100m1 premix Lead ceramic powder, ball milled for 12 hours to make a suspension of lead niobium magnesium zirconate titanate ceramics with a solid phase volume fraction of 10%, that is, the volume of lead niobium magnesium zirconate titanate occupies 10% of the total volume of the material. Add 150 μl of initiator ammonium persulfate solution (35wt%) and 1.0ml of foaming agent acetic acid into the suspension, and stir rapidly to foam. The ceramic foam is poured into the mold, and placed in a low-temperature constant temperature freezing tank at a temperature of -20°C for 10 hours to form. Immediately after taking out the frozen green body, place it in an electric drying oven at a temperature of 180°C, and the hydroxyethyl methacrylate monomer undergoes a curing reaction under the joint action...

Embodiment 3

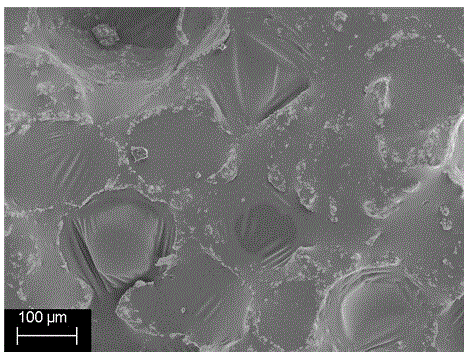

[0038] Dissolve 15.5wt% hydroxypropyl methacrylate monomer and 0.5wt% crosslinking agent methylenebisacrylamide in 84wt% water to make a premix; add niobium lithium zirconium titanate to 100m1 premix Lead ceramic powder, ball milled for 12 hours to make a suspension of niobium lithium zirconate lead titanate ceramics with a solid phase volume fraction of 20%, that is, the volume of niobium lithium zirconate lead titanate occupies 20% of the total volume of the material. Add 200 μl of initiator ammonium persulfate solution (35wt%) and 1.5ml of foaming agent propionic acid into the suspension, and stir rapidly to foam. The ceramic foam is poured into the mold, and placed in a low-temperature constant temperature freezing tank at a temperature of -20°C for 18 hours to form. Immediately after taking out the frozen green body, place it in an electric drying oven at a temperature of 150°C, and the hydroxypropyl methacrylate monomer undergoes curing reaction under the joint action o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com