Copper-tungsten composite material with microscopic oriented structure and preparation method thereof

A composite material and a microscopic technology, applied in the field of copper-tungsten composite material with a microscopic directional structure and its preparation, can solve the problems affecting the use effect and life, the inconsistency of the microstructure and performance, and the reduction of the plasticity and toughness of the composite material. Excellent electrical and thermal conductivity, improve utilization efficiency and use effect, improve plasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

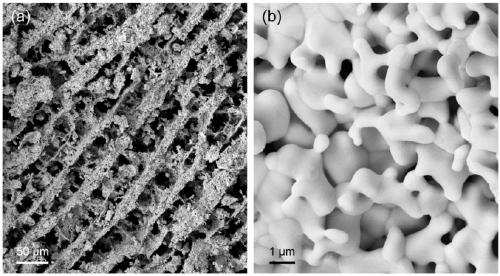

[0040] The raw materials used in this example mainly include tungsten powder (average particle diameter 500nm), copper powder (average particle diameter 50nm), deionized water, hydroxypropyl methylcellulose powder (average particle diameter 180μm), polyacrylic acid and infiltration Using pure copper block, the specific preparation process is as follows:

[0041] (A) Slurry preparation: Take 228g of deionized water and add it to a 500ml plastic jar, add 419g of tungsten powder and 33.2g of copper powder to the jar in turn, and use a glass rod to stir at a speed of 80rpm for 5min to make the tungsten Powder and copper powder are evenly dispersed in water. Place the jar in a constant temperature water bath at 70°C, keep it warm for 30 minutes, slowly add 3.4g of hydroxypropyl methylcellulose powder into the jar, and stir until the powder is evenly dispersed in the slurry. Take out the jar from the constant temperature water bath, and after the slurry is cooled, add 2.3 g of poly...

Embodiment 2

[0048] The raw materials used in this example are the same as those in Example 1, and the difference between the specific preparation process and Example 1 is that the mass of deionized water added in the slurry preparation process is 145.6g, the mass of tungsten powder is 404g, copper The quality of powder is 32.8g, the quality of hydroxypropyl methylcellulose powder is 7.3g, the quality of polyacrylic acid is 2.2g, all the other operations are identical with embodiment 1.

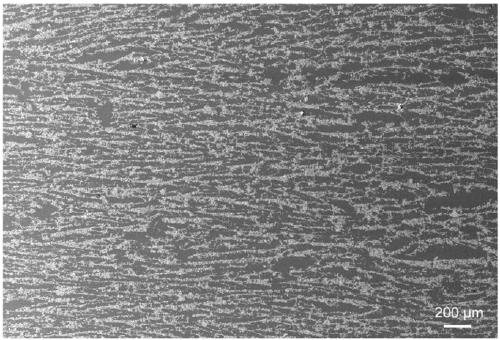

[0049] Copper-tungsten composite materials with micro-oriented lamellar structure can be prepared through the above-mentioned process, and its micro-structure can be seen in Figure 4 . Depend on Figure 4It can be seen that the volume fraction of tungsten in the composite material is 41%, and the corresponding mass fraction is 60%. After testing, the hardness of the composite material along the lamellar direction is 1.97GPa, the hardness perpendicular to the lamellar direction is 1.85GPa, the compressi...

Embodiment 3

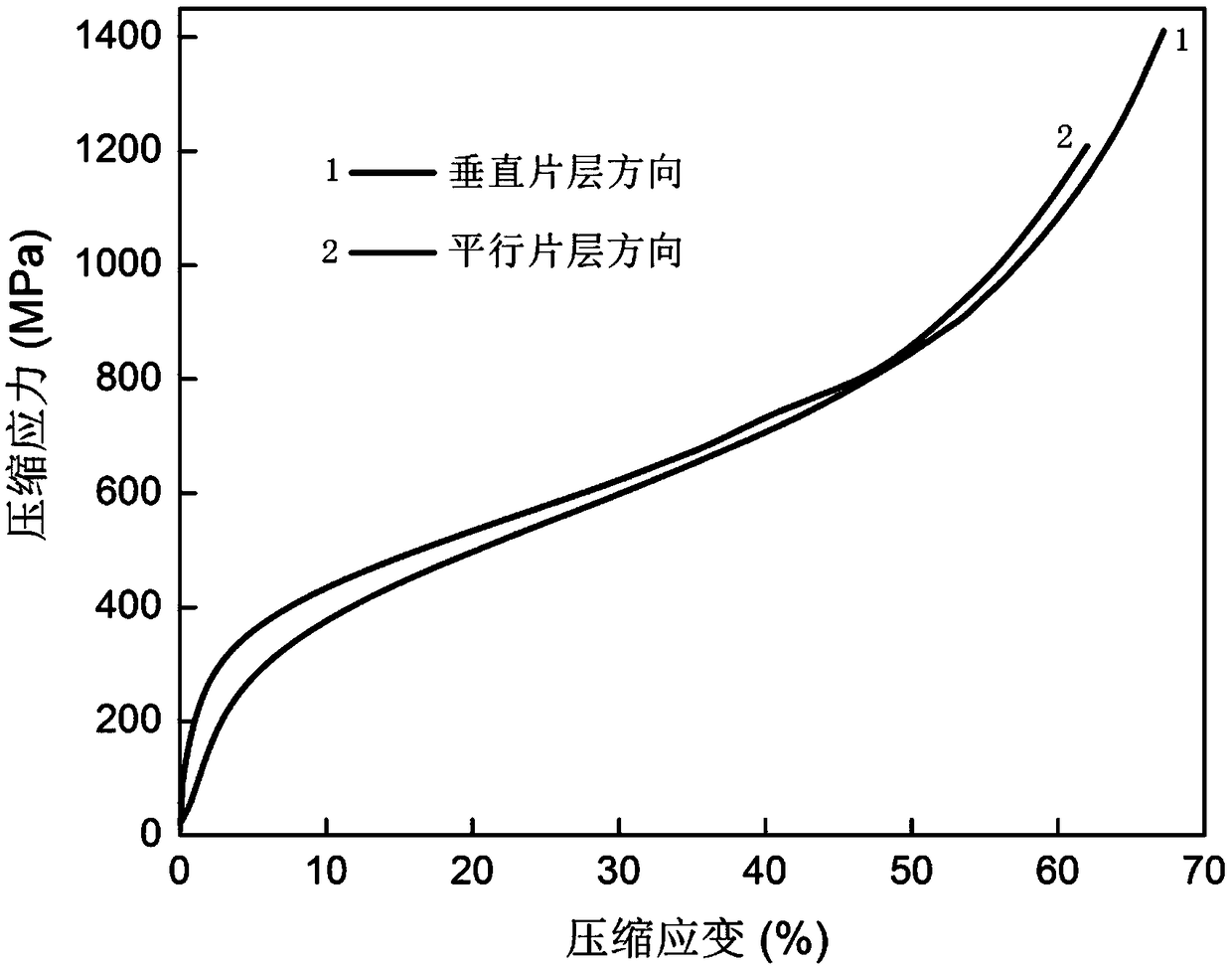

[0051] The raw materials used in this example are the same as in Example 1, and the specific preparation process differs from Example 1 in that the mass of deionized water added in the slurry preparation process is 121.5g, the mass of tungsten powder is 450g, copper The quality of powder is 36.4g, the quality of hydroxypropyl methylcellulose powder is 7.9g, the quality of polyacrylic acid is 2.4g, all the other operations are identical with embodiment 1.

[0052] A copper-tungsten composite material with a microscopically oriented lamellar structure can be prepared through the above-mentioned process. The volume fraction of tungsten in the composite material is 46%, and the corresponding mass fraction is 65%. After testing, the hardness of the composite material along the sheet direction is 2.15GPa, the hardness perpendicular to the sheet direction is 2.07GPa, the compressive strength along the sheet direction at room temperature is 630MPa, the electrical conductivity is 50% IA...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average spacing | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com